Advanced Enzyme Immobilization Techniques for Continuous-Flow Biocatalysis in Pharmaceutical Development

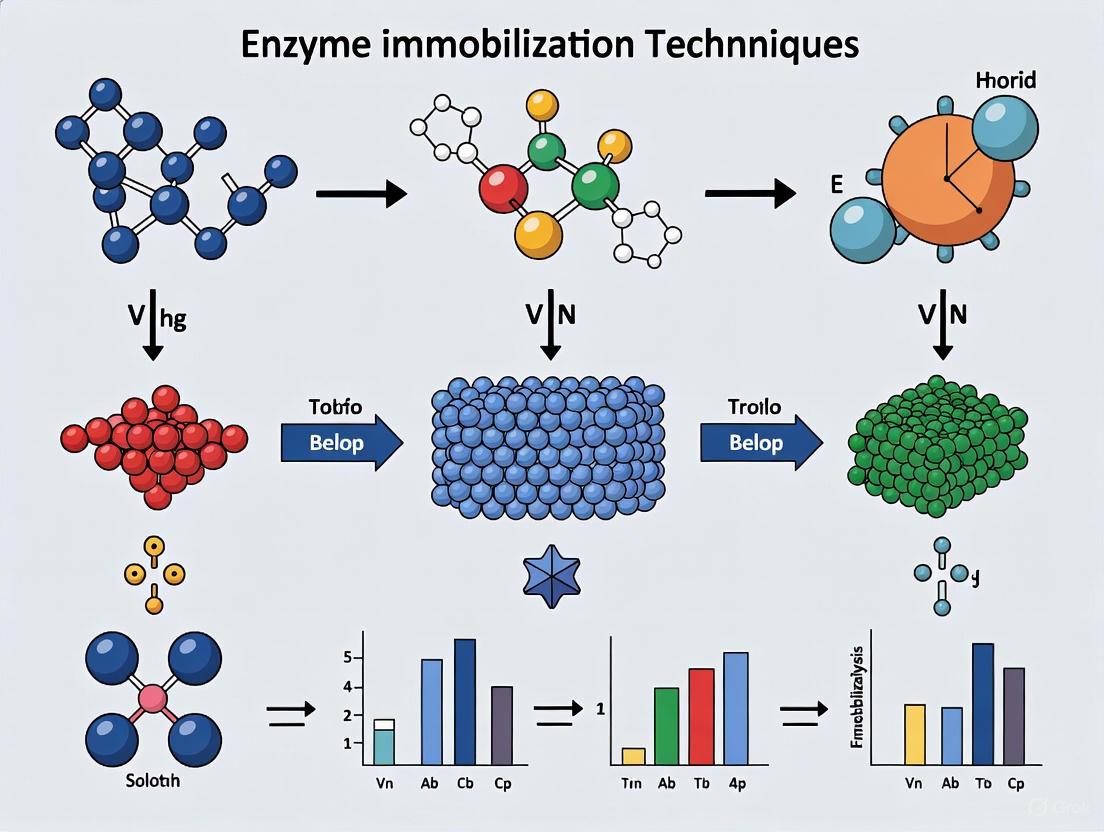

This article provides a comprehensive analysis of modern enzyme immobilization strategies tailored for continuous-flow systems, a key technology for sustainable and efficient pharmaceutical synthesis.

Advanced Enzyme Immobilization Techniques for Continuous-Flow Biocatalysis in Pharmaceutical Development

Abstract

This article provides a comprehensive analysis of modern enzyme immobilization strategies tailored for continuous-flow systems, a key technology for sustainable and efficient pharmaceutical synthesis. Aimed at researchers, scientists, and drug development professionals, it explores the fundamental principles driving the adoption of flow biocatalysis, details a wide range of carrier-bound and carrier-free immobilization methodologies, and offers practical guidance for troubleshooting common challenges. By presenting validated performance metrics and comparative analyses of techniques across different pharmaceutical applications, this guide serves as a strategic resource for selecting, optimizing, and implementing immobilized enzyme reactors to enhance process intensification, reduce environmental impact, and lower production costs in biomedical research and manufacturing.

The Foundation of Flow Biocatalysis: Principles and Drivers for Pharmaceutical Applications

Continuous-flow biocatalysis represents a paradigm shift in enzymatic synthesis, merging the exceptional selectivity of biocatalysts with the enhanced efficiency of continuous manufacturing. This approach involves enzymes—either in purified or whole-cell form—immobilized within a flow reactor, through which substrate solutions are continuously pumped to yield a steady stream of product [1] [2]. The integration of biocatalysis and continuous flow technology has opened powerful new process windows for the synthesis of pharmaceuticals, value-added chemicals, and materials, offering improved mixing, mass transfer, thermal control, and automation compared to traditional batch systems [3] [1]. For researchers focused on enzyme immobilization, flow biocatalysis provides a compelling framework to leverage immobilization techniques for creating robust, reusable, and highly efficient biocatalytic systems capable of long-term operation, thereby addressing key challenges in sustainable process chemistry [4] [5].

Fundamental Advantages Over Batch Processing

The transition from batch to continuous-flow processing addresses several intrinsic limitations of traditional batch reactors, particularly when applied to biocatalytic transformations. The table below summarizes the core advantages:

Table 1: Key Advantages of Continuous-Flow Biocatalysis over Batch Processing

| Feature | Batch Biocatalysis | Continuous-Flow Biocatalysis | Primary Impact |

|---|---|---|---|

| Process Safety | Large reagent volumes present significant safety risks with hazardous materials [6]. | Small, contained reagent volumes at any given time; inherent safety [7] [6]. | Enables safer use of hazardous intermediates and conditions. |

| Heat/Mass Transfer | Poor mixing and heat transfer; prone to hot/cold spots [7]. | Excellent heat and mass transfer due to high surface-to-volume ratios [1] [7]. | Superior control over reaction kinetics and selectivity. |

| Reproducibility & Scalability | Significant batch-to-batch variability; scale-up is non-linear and complex [7]. | Highly consistent steady-state conditions; scale-up via longer operation ("numbering up") [7] [6]. | Reduces development time and de-risks process transfer. |

| Catalyst Stability & Reuse | Catalyst recovery often difficult, leading to attrition and loss per cycle [5]. | Immobilized catalyst used continuously for extended periods (e.g., weeks to months) [8] [9]. | Dramatically reduces catalyst consumption and cost. |

| Process Integration & Automation | Difficult to automate; work-up and purification are typically discrete steps [7]. | Seamless integration with in-line purification, analysis, and automated optimization [1] [7] [8]. | Accelerates reaction development and intensifies processes. |

| Reaction Time | Can require days for full conversion [8]. | Dramatically reduced (e.g., from days to minutes/hours) [8]. | Increases productivity and throughput. |

These advantages are enabled by the fundamental design of flow reactors. In a typical packed-bed reactor (PBR), the immobilized enzyme is contained in a fixed cartridge, providing a stable environment where reactants are converted to products as they flow through the catalyst bed [1]. This setup allows for precise control of residence time—a key reaction parameter—by simply adjusting the flow rate [7]. Furthermore, the system can be pressurized using a back-pressure regulator, allowing solvents to be heated above their atmospheric boiling points, which opens novel process windows not accessible in batch [1].

Essential Immobilization Techniques for Flow Systems

Enzyme immobilization is a critical enabling technology for continuous-flow biocatalysis, as it prevents enzyme washout, facilitates reuse, and often enhances stability [4] [5]. The choice of immobilization strategy directly impacts the performance, longevity, and efficiency of the flow biocatalytic system.

Table 2: Common Enzyme Immobilization Techniques for Flow Biocatalysis

| Technique | Principle | Advantages | Disadvantages | Suitability for Flow |

|---|---|---|---|---|

| Adsorption [1] [5] | Enzyme bound via weak interactions (hydrophobic, ionic, van der Waals). | Simple procedure; low cost; minimal enzyme conformation distortion. | Enzyme leaching under operational conditions (flow, solvents). | Moderate (risk of leaching under continuous flow). |

| Covalent Binding [1] [5] | Formation of irreversible covalent bonds between enzyme and support. | Strong attachment; minimal leaching; high operational stability. | Potential loss of activity due to harsh conditions or rigidification. | High (excellent for long-term continuous use). |

| Entrapment/ Encapsulation [9] [5] | Enzyme physically confined within a porous polymer matrix or membrane. | Protects enzyme from harsh environments (e.g., shear, solvents). | Mass transfer limitations for substrate and product. | High (especially with robust, porous matrices). |

| Affinity Immobilization [1] [5] | Highly specific, reversible binding (e.g., His-tag to metal ions). | Controlled, uniform orientation; can preserve high activity. | Requires genetically modified enzymes; can be expensive. | High (offers precise control and potential for reactor regeneration). |

A recent innovative example is the development of a porous "interphase" for enzyme immobilization, inspired by cell membranes. In this approach, Candida antarctica lipase B (CALB) was incorporated within a nanometer-thick, porous silica shell at the water-oil interface of Pickering emulsion droplets. This design allows the enzyme to maintain contact with an aqueous microenvironment while being accessible to organic reactants in the oil phase. This system demonstrated exceptional long-term stability, operating continuously for over 800 hours in a flow epoxidation reaction, and achieved a 16-fold increase in catalytic efficiency compared to the batch reaction [9].

Application Notes and Case Studies

Application Note 001: Chemo-Enzymatic Synthesis of an API (Captopril)

Objective: To develop a continuous, scalable, and stereoselective synthesis of the antihypertensive drug Captopril [8].

Flow Setup and Protocol:

- Reactor Configuration: A segmented air-liquid flow stream system followed by packed-bed reactors for subsequent chemical steps.

- Key Biocatalytic Step: Oxidation of 2-methyl-1,3-propandiol using Ca-alginate-immobilized cells of Acetobacter aceti in the first reactor. Air was segmented into the stream to supply oxygen.

- Downstream Processing: The output from the biocatalytic reactor was directly fed into subsequent flow reactors for chlorination, amide coupling, and nucleophilic substitution. In-line liquid-liquid separations and quenching were implemented.

Results and Advantages:

- Dramatically Reduced Reaction Time: The overall process time was reduced from 3 days in batch to 100 minutes in flow.

- Increased Yield: The overall yield improved from 45% (batch) to 65% (flow).

- Process Simplification: The need for traditional work-up and intermediate purification was minimized, with only a single final chromatography step required [8].

Application Note 002: Stereoselective Synthesis using Immobilized Ketoreductase (KRED)

Objective: To achieve continuous, cofactor-dependent, stereoselective reduction of diketones to chiral mono-alcohols, key intermediates for hormonal contraceptives [8].

Flow Setup and Protocol:

- Reactor Configuration: A single packed-bed reactor (PBR).

- Immobilization & Cofactor Recycling: The PBR was packed with a mixed bed of two co-immobilized enzymes: a Ketoreductase (KRED) and a Glucose Dehydrogenase (GDH). The GDH regenerated the NADP+ cofactor by oxidizing glucose to gluconic acid.

- Process Parameters: Substrate solution was continuously pumped through the PBR. Residence times were optimized between 7 minutes and 3 hours.

Results and Advantages:

- Long-Term Stability: The flow reactor maintained stable conversion for 15 days of continuous operation.

- Exceptional Catalyst Longevity: After 6 months of operation, the reactor retained 68-70% of its original activity.

- High Productivity: Achieved complete conversion to enantiopure mono-alcohols [8].

The Scientist's Toolkit: Essential Reagents and Materials

Table 3: Key Research Reagent Solutions for Flow Biocatalysis

| Item Category | Specific Examples | Function / Application in Flow Biocatalysis |

|---|---|---|

| Enzymes | Ketoreductases (KREDs), Glucose Dehydrogenase (GDH), Transaminases, Lipases (e.g., CALB) [8] [9] | Catalyze stereoselective transformations (reductions, aminations, epoxidations). |

| Immobilization Supports | Silica-based supports, Alginate beads, Epoxy-activated resins, Chitosan, Agarose/Sepharose [1] [8] [5] | Solid carriers for enzyme immobilization via adsorption, covalent binding, or entrapment. |

| Flow Reactors | Packed-Bed Reactors (PBR), Tube-in-Tube reactors (for gases) [1] [8] | Housing for immobilized biocatalysts; enable continuous processing and precise residence time control. |

| Cofactors | NAD(P)+ / NAD(P)H | Essential co-substrates for oxidoreductases; often regenerated in situ using a second enzyme/substrate pair. |

| Pumping Systems | Syringe pumps, Peristaltic pumps [1] | Provide continuous and precise fluid delivery through the flow system. |

| Process Analytical Technology (PAT) | In-line IR/UV sensors [7] | Enable real-time monitoring of conversion, yield, and impurity profiles for process control. |

Experimental Protocol: General Procedure for a Packed-Bed Biocatalytic Flow Reactor

This protocol outlines the steps for setting up and operating a continuous-flow biocatalysis system using an immobilized enzyme in a packed-bed reactor, suitable for a wide range of syntheses.

Workflow Overview:

Materials:

- Immobilized enzyme (e.g., covalently immobilized Ketoreductase on epoxy resin)

- Appropriate buffer solution (e.g., phosphate buffer, 50 mM, pH 7.0)

- Substrate solution in suitable solvent/buffer

- Packed-bed reactor (e.g., empty HPLC column)

- HPLC pump or syringe pump capable of continuous flow

- Tubing and connectors (e.g., PFA)

- Back-pressure regulator

- Fraction collector or automated sample collector

- Equipment for analysis (HPLC, GC, etc.)

Step-by-Step Procedure:

Enzyme Immobilization:

- Immobilize the target enzyme onto your chosen solid support (e.g., silica, polymer resin) using a selected method (e.g., covalent binding with epoxide chemistry) [5]. Determine the immobilization yield and activity of the prepared biocatalyst in batch mode prior to packing.

Reactor Packing:

- Slurry the immobilized enzyme particles in a degassed equilibration buffer.

- Carefully pour the slurry into the empty reactor column to avoid creating air bubbles.

- Connect the column to the pump and pack the bed by pumping equilibration buffer at a gradually increasing flow rate until a stable, compact bed is formed.

System Assembly:

- Connect the packed reactor column to the flow system. Ensure all fluidic connections are secure.

- Install a back-pressure regulator downstream of the reactor to pressurize the system and prevent solvent outgassing [1].

Conditioning & Equilibration:

- Pump equilibration buffer through the system for at least 5-10 column volumes to condition the immobilized enzyme and stabilize the system parameters (pressure, pH).

Substrate Processing:

- Switch the pump inlet from the buffer reservoir to the substrate solution.

- Set the desired flow rate to achieve the target residence time (Residence Time = Reactor Volume / Flow Rate).

- Begin collecting the reactor effluent. The initial output may not be at steady state; allow 2-3 residence times to pass before collecting samples for analysis.

Process Monitoring:

- Collect fractions periodically or use in-line analytical probes (e.g., UV) to monitor conversion, product formation, and system performance [7].

- Record system pressure and flow rate consistently to monitor for potential clogging or catalyst bed degradation.

Shutdown & Storage:

- To shut down, switch the pump back to the equilibration buffer and flush the system with 5-10 column volumes to remove any residual substrate and product.

- The packed-bed reactor can often be stored in buffer at 4°C for future use. Document the total operational runtime for catalyst lifetime assessment.

Continuous-flow biocatalysis firmly establishes itself as a superior platform for modern synthetic applications, particularly in the synthesis of enantiopure pharmaceuticals and fine chemicals. By effectively leveraging enzyme immobilization techniques, this technology delivers unmatched advantages in process efficiency, sustainability, and control over traditional batch methods. The ability to operate continuously for extended periods—from weeks to months—while maintaining high catalytic activity and stereoselectivity, translates directly into reduced costs and waste, aligning with the principles of green chemistry. As innovations in immobilization, reactor design, and process integration with analytical technologies continue to emerge, the adoption and impact of continuous-flow biocatalysis are poised to expand significantly, solidifying its role as a cornerstone of future biocatalytic manufacturing.

Enzyme immobilization has evolved into a powerful tool for biocatalyst engineering, playing a critical role in enhancing the efficiency and sustainability of biocatalysis [5]. This technology addresses key challenges such as limited enzyme stability, short shelf life, and difficulties in recovery and recycling, which are pivotal for green chemistry and industrial applications [5]. For researchers working in continuous flow systems—a growing focus in bioprocessing—immobilization provides the foundation for fixed-bed reactors that enable continuous operation over extended periods [10] [3].

The fundamental principle behind enzyme immobilization involves physically confining or localizing enzymes in a defined region of space while retaining their catalytic activities, allowing for repeated and continuous use [10]. The principal components of any immobilized enzyme system include the enzyme itself, the support matrix, and the mode of attachment between them [10]. Proper selection of these components enables optimal immobilization outcomes, though it is important to recognize that an enzyme may undergo changes in chemical and physical properties upon immobilization, depending on the chosen method [10].

Core Benefits of Enzyme Immobilization

Enhanced Enzyme Stability

Immobilization significantly improves enzyme stability under various operational conditions, including extreme pH levels, high temperatures, and exposure to solvents, surfactants, or metal ions [5] [11]. This stabilization occurs through multiple mechanisms: the support matrix can maintain the enzyme's tertiary structure by forming electron transition complexes, hydrogen bonds, or covalent bonds [10]. In cases of multipoint covalent attachment, the enzyme is restricted from adopting inactive conformations, thereby enhancing its stability [12].

Table 1: Quantitative Improvements in Enzyme Stability Achieved Through Immobilization

| Enzyme | Support Material | Stability Improvement | Experimental Conditions |

|---|---|---|---|

| Recombinant Chitinase A (SmChiA) [13] | Sodium alginate-modified rice husk beads | Enhanced pH, temperature, and storage stability compared to free enzyme | Retained activity over 22 reuse cycles |

| Calf Intestinal Alkaline Phosphatase (CIAP) [12] | Benzophenone-modified polyacrylamide (BPMA-PAAm) gel films | Improved operational stability for continuous use | Reaction-limited regime (Weisz's modulus Φ ≪ 0.15) |

| General Enzymes [11] | Various solid supports | Increased resistance to denaturation from detergents, solvents, and impurities | Broad industrial application conditions |

The conformational stability afforded by immobilization is particularly valuable for continuous flow applications where enzymes may be subjected to varying process conditions over extended operational periods [5] [12].

Enzyme Reusability and Cost Efficiency

The capacity to recover and reuse enzymes represents one of the most significant economic advantages of immobilization technology [5] [10]. Immobilization enables facile separation of enzymes from reaction mixtures, allowing their repeated application in multiple catalytic cycles [11]. This reuse capability substantially reduces process costs by decreasing enzyme consumption per unit of product formed [10].

In the case of recombinant chitinase A immobilized on sodium alginate-modified rice husk beads, the preparation demonstrated remarkable durability, maintaining full activity through 22 reuse cycles [13]. This exceptional reusability translates directly to reduced operational costs for industrial processes. Similarly, various immobilized enzyme systems have shown the ability to maintain catalytic activity through numerous batch cycles or extended continuous operation in flow reactors [5].

Table 2: Reusability and Kinetic Parameters of Immobilized Enzymes

| Enzyme | Support Material | Reusability | Kinetic Parameters | Reference |

|---|---|---|---|---|

| Recombinant Chitinase A (SmChiA) [13] | Sodium alginate-modified rice husk beads | 22 reuse cycles with maintained activity | Km = 3.33 mg/mL; Vmax = 4.32 U/mg protein/min | [13] |

| Calf Intestinal Alkaline Phosphatase (CIAP) [12] | BPMA-PAAm gel films | Extended continuous operation in flow systems | ~2× loss in apparent Km; ~200× decrease in kcat | [12] |

Simplified Downstream Processing

Immobilization dramatically simplifies downstream processing by enabling rapid separation of the biocatalyst from reaction products [10] [11]. This facile separation minimizes or avoids protein contamination of the product altogether, reducing purification requirements and costs [10]. In continuous flow systems with immobilized enzymes, the reaction products exit the reactor while the enzymes remain retained within the support matrix, effectively integrating reaction and separation into a single unit operation [3].

The ability to rapidly arrest enzymatic reactions by simply removing the immobilized enzyme from the reaction solution provides additional control over reaction progress and product quality [10]. This feature is particularly valuable in the production of pharmaceuticals and fine chemicals where precise reaction control is essential [5].

Relationship Between Core Benefits in Continuous Flow Systems

The core benefits of enzyme immobilization create a synergistic effect that is particularly advantageous in continuous flow systems. The following diagram illustrates how these benefits interrelate:

Experimental Protocols

Covalent Immobilization of Recombinant Chitinase A on Sodium Alginate-Modified Rice Husk Beads

Background: This protocol describes the covalent immobilization of Serratia marcescens chitinase A (SmChiA) onto beads comprised of sodium alginate (SA) and modified rice husk powder (mRHP) for enhanced stability and reusability in dye decolorization applications [13].

Materials:

- Rice husk powder (RHP) with average particle size of 300 μm

- Citric acid (CA)

- 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide (EDAC)

- Calcium chloride (CaCl₂)

- Sodium alginate (SA)

- Recombinant SmChiA enzyme

Procedure:

Modification of RHP by Citric Acid:

- Mix 5 g of RHP with citric acid (dissolved in minimal water) under continuous stirring until a homogeneous paste forms.

- Dry the paste in a petri dish at 60°C for 2 hours.

- Incubate at 120°C for 12 hours.

- After incubation, dilute with distilled water, vacuum-filter to separate the modified RHP (mRHP), and wash thoroughly [13].

Bead Preparation:

- Combine sodium alginate with mRHP at three different concentrations (25%, 50%, and 100% of SA weight).

- Cross-link with calcium chloride to form beads [13].

Enzyme Immobilization:

- Activate beads with EDAC to facilitate formation of amide bonds that covalently bind SmChiA to the beads.

- Use 1.75 UmL⁻¹ of enzyme solution for immobilization.

- Conduct immobilization for 5 hours for optimal results [13].

Validation:

- Confirm effectiveness of synthesis and immobilization using scanning electron microscopy (SEM) and Fourier transform infrared spectroscopy (FTIR) [13].

- Evaluate immobilization efficiency by measuring enzyme activity before and after immobilization.

Immobilization of Calf Intestinal Alkaline Phosphatase in BPMA-PAAm Gels for Kinetic Studies

Background: This protocol describes the immobilization of calf intestinal alkaline phosphatase (CIAP) in benzophenone-modified polyacrylamide (BPMA-PAAm) gel films for detailed kinetic analysis free from mass transport artifacts [12].

Materials:

- N-[3-[(3-Benzoylphenyl)-formamido]propyl]methacrylamide (BPMA)

- Acrylamide/bis-acrylamide (29:1)

- N,N,N′,N′-tetramethylethylenediamine (TEMED)

- Ammonium persulfate (APS)

- Calf intestinal alkaline phosphatase (CIAP)

- AlexaFluor488 labeling kit

- 6,8-Difluoro-4-methylumbelliferyl phosphate (DiFMUP)

Procedure:

Gel Fabrication:

- Fabricate BPMA-PAAm gels (8%T, 3.3%C, 3 mM BPMA comonomer) using an SU-8 mold with ~43 μm tall features.

- For fluorescent quantification, label CIAP with AlexaFluor488 according to manufacturer's instructions prior to immobilization [12].

Enzyme Immobilization:

- Incorporate fluorescently labeled CIAP (CIAP*) during gel fabrication.

- Immobilize enzymes via benzophenone photochemistry upon UV exposure [12].

Kinetic Characterization:

- Measure reaction kinetics of immobilized CIAP in fluidically isolated chambers.

- Employ Weisz's modulus (Φ) to ensure kinetics measurements occur in a reaction-limited regime (Φ ≪ 0.15) to avoid mass transport limitations.

- Use bootstrapping computational method to propagate uncertainty in each step of data analysis onto final Km, Vmax, and kcat estimates [12].

Validation:

- Confirm absence of mass transport limitations using Weisz's modulus.

- Compare kinetic parameters (Km, kcat) with free enzyme values.

- Utilize bootstrapping to estimate uncertainty in derived parameters.

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 3: Key Research Reagents for Enzyme Immobilization Protocols

| Reagent | Function/Application | Example Use Case |

|---|---|---|

| Sodium Alginate (SA) [13] | Natural anionic polysaccharide for bead formation; forms gels with divalent cations | Matrix for chitinase immobilization with modified rice husk powder |

| 1-Ethyl-3-(3-dimethylaminopropyl) carbodiimide (EDAC) [13] | Crosslinking agent facilitating amide bond formation | Covalent immobilization of enzymes to alginate beads |

| Benzophenone-modified polyacrylamide (BPMA-PAAm) [12] | Photoreactive gel matrix for enzyme entrapment | Immobilization of CIAP for kinetic studies in flow systems |

| Glutaraldehyde [11] | Multifunctional reagent for covalent attachment | Formation of self-assembled monolayers on carrier surfaces |

| Agarose-based supports [11] | Versatile chromatography matrix for enzyme binding | Multipoint covalent immobilization for enzyme stabilization |

| Sartobind IDA Lab [14] | Immobilized metal affinity chromatography (IMAC) membrane | Purification of his-tagged recombinant enzymes prior to immobilization |

Enzyme immobilization provides three fundamental benefits—enhanced stability, improved reusability, and simplified downstream processing—that collectively address key limitations in biocatalytic applications, particularly in continuous flow systems. The experimental protocols presented enable researchers to implement covalent immobilization methods that maximize these benefits while maintaining enzymatic activity. As immobilization technologies continue to evolve alongside advances in enzyme engineering and support material design, their application in pharmaceutical development, fine chemical synthesis, and environmental biotechnology is expected to expand significantly [5] [3]. The essential reagent solutions outlined provide researchers with a foundational toolkit for developing immobilized enzyme systems tailored to their specific continuous flow applications.

Continuous flow biocatalysis has emerged as a sustainable and efficient approach for chemical synthesis, particularly in the pharmaceutical and fine chemicals industries. The integration of immobilized enzymes into continuous flow systems enables improved reaction control, enhanced productivity, and simplified downstream processing. This application note details three pivotal reactor configurations—packed-bed, membrane, and microreactors—within the context of advanced enzyme immobilization techniques for continuous flow research. We provide a structured comparison, detailed experimental protocols, and essential resource guidance to facilitate implementation across research and development settings.

Comparative Analysis of Reactor Configurations

The selection of an appropriate reactor configuration is paramount for optimizing continuous flow biocatalytic processes. The table below summarizes the key characteristics, advantages, and challenges of packed-bed, membrane, and microreactor systems.

Table 1: Comparison of Continuous Flow Biocatalytic Reactor Configurations

| Parameter | Packed-Bed Reactor (PBR) | Membrane Reactor (MR) | Microreactor (MR) |

|---|---|---|---|

| Basic Principle | Column packed with immobilized enzyme particles or carriers [1]. | Enzyme is immobilized on/in a membrane or retained by it; reaction and separation can be coupled [15]. | Microfabricated channels (10-500 µm) with immobilized enzymes [16] [17]. |

| Immobilization Method | Typically carrier-based: adsorption, covalent attachment, or CLEAs [1] [18]. | Immobilization on membrane surface/pores, or free enzymes confined by a membrane [19] [15]. | In-channel immobilization via adsorption, covalent bonding, or entrapment [16]. |

| Surface-to-Volume Ratio | High (carrier-dependent) | High (membrane-dependent) | Very High (10,000 - 50,000 m²/m³) [17] |

| Mass/Heat Transfer | Good, but can be limited by internal diffusion in particles. | Can be enhanced by membrane design and flow. | Excellent; mixing is diffusion-dominated, enabling superior heat and mass transfer [17]. |

| Pressure Drop | High, especially with small particles. | Moderate, depends on membrane porosity and thickness. | Low to moderate [20]. |

| Residence Time Control | Good, controlled by flow rate and bed volume. | Good. | Precise, due to laminar flow and small dimensions [16]. |

| Typical Applications | Large-scale production, multi-enzyme cascades [1]. | Continuous synthesis with integrated product separation, processing of sensitive products [19] [15]. | Process screening, kinetic studies, production of high-value low-volume chemicals [16] [17]. |

| Key Advantages | Simplicity, high catalyst loading, scalability. | Integration of reaction and separation, potential for continuous operation with free enzymes. | Minimal reagent consumption, rapid process optimization, high controllability [16] [17]. |

| Key Challenges | Channeling, high pressure drop, catalyst leaching. | Membrane fouling, concentration polarization, additional cost of membranes. | Susceptibility to clogging, limited throughput per device, scalability requires numbering-up [17]. |

Experimental Protocols for Key Configurations

Protocol: Fabrication of a High-Performance Enzymatic Membrane Reactor

This protocol outlines the procedure for fabricating a high-performance enzymatic membrane reactor (NaMeR) using an isoporous block copolymer membrane and a material-binding peptide (MBP) for oriented enzyme immobilization, as demonstrated by Kressierer et al. [19].

Research Reagent Solutions

- Membrane Material: Asymmetric polystyrene-block-poly(4-vinyl pyridine) (PS-b-P4VP) isoporous membrane (cylindrical top layer thickness: ~350 nm, nanochannel diameter: ~57.5 nm) [19].

- Enzyme Construct: Phytase from Yersinia mollaretii (YmPh) genetically fused with the Liquid Chromatography peak I (LCI) material-binding peptide (YmPh-LCI) [19].

- Buffers: Immobilization buffer (e.g., 50 mM phosphate buffer, pH 7.0). Activity assay buffer (e.g., 100 mM sodium acetate, pH 5.5) containing the substrate (e.g., phytate) [19].

Methodology

- Membrane Preparation: Fabricate the PS-b-P4VP isoporous membrane via a combination of evaporation-induced self-assembly and nonsolvent-induced phase separation (SNIPS). Characterize the nanochannel diameter and porosity using electron microscopy [19].

- Enzyme Immobilization:

- Equilibrate the membrane with a suitable immobilization buffer.

- Recirculate or perfuse a solution of YmPh-LCI (concentration to be optimized, e.g., ~0.1 mg/mL) through the membrane for a predetermined time (e.g., 1-2 hours) at ambient temperature.

- Wash the membrane extensively with buffer to remove any non-specifically bound enzyme, resulting in YmPh-LCI@M [19].

- Reactor Assembly: Integrate the functionalized membrane into a suitable housing to create a flow cell. Connect to a syringe or HPLC pump for continuous operation.

- Continuous Flow Reaction:

- Pump the substrate solution (phytate in activity assay buffer) through the YmPh-LCI@M membrane reactor at a defined flow rate.

- Monitor the product (phosphate) formation in the effluent using an appropriate analytical method (e.g., malachite green assay or HPLC).

- Performance Validation: Determine operational stability by monitoring conversion over extended periods (e.g., >1 month). Calculate space-time yield (e.g., target: ~1.05 × 10⁵ g L⁻¹ d⁻¹) [19].

Protocol: Development of an Enzyme-Packed Bed Reactor

This protocol describes the establishment of a packed-bed reactor (PBR) using enzymes immobilized on porous particles, a workhorse configuration for scalable continuous flow biocatalysis [1].

Research Reagent Solutions

- Carrier Material: Porous resin (e.g., Eupergit C, epoxy-functionalized silica, or amino-functionalized polymer beads) [1] [18].

- Enzyme: Target enzyme (e.g., lipase, transaminase). For covalent immobilization, ensure the enzyme has accessible surface lysines.

- Cross-linker: Glutaraldehyde solution (e.g., 2.5% v/v in buffer) for activation of amino-bearing supports [1].

Methodology

- Support Activation (Covalent Immobilization):

- If using an amino-functionalized support, wash the beads with a coupling buffer (e.g., 0.1 M phosphate buffer, pH 7.5).

- Incubate the beads with a glutaraldehyde solution (2.5-5.0%) for 1-2 hours with gentle agitation.

- Wash thoroughly with coupling buffer to remove excess glutaraldehyde [1].

- Enzyme Immobilization:

- Dissolve the purified enzyme in the coupling buffer.

- Mix the enzyme solution with the activated support and incubate for several hours (e.g., 4-16 hours) at 4°C with gentle mixing.

- Drain the solution and wash the immobilized enzyme beads extensively with buffer, followed by a high-ionic-strength buffer (e.g., with 1 M NaCl) and finally with reaction buffer to remove any adsorbed enzyme.

- Reactor Packing:

- Pack the immobilized enzyme slurry into a suitable column (e.g., an HPLC column).

- Ensure uniform packing to minimize channeling and high backpressure. The bed volume determines the residence time.

- Continuous Flow Operation:

- Connect the column to a pump and pre-equilibrate with the reaction buffer.

- Pump the substrate solution through the column at the desired flow rate.

- Collect the effluent and analyze for product formation.

Protocol: Setting Up an Enzyme Microreactor for Process Screening

This protocol provides guidance for creating a capillary-based enzyme microreactor, ideal for rapid process optimization and kinetic studies [16] [17].

Research Reagent Solutions

- Microreactor: Fused silica capillary (e.g., 100 µm inner diameter, 10-30 cm length) or a commercial glass/PMMA chip.

- Enzyme: Target enzyme, often His-tagged for simplified immobilization.

- Immobilization Matrix: Ni-NTA agarose or silica beads, or reagents for surface derivatization (e.g., 3-aminopropyltriethoxysilane and glutaraldehyde) [16].

Methodology

- Surface Functionalization (Capillary Reactor):

- Flush the capillary with NaOH (1.0 M), water, and then an organic solvent (e.g., acetone).

- Perfuse the capillary with a solution of 3-aminopropyltriethoxysilane (2% in acetone) and incubate to create an amino-functionalized surface.

- Rinse and then activate the surface with glutaraldehyde solution (2.5% in buffer) [16].

- Enzyme Immobilization:

- For covalent binding, perfuse the enzyme solution through the activated capillary and incubate.

- For affinity immobilization, pack the capillary with Ni-NTA agarose beads and then load a His-tagged enzyme solution [16].

- Reactor Operation:

- Connect the functionalized microreactor to a syringe pump.

- Pump the substrate solution through the microreactor at very low flow rates (µL/min).

- The small dimensions ensure rapid mixing and heat transfer, allowing for precise kinetic measurements [17].

- Collect the effluent for analysis or connect directly to an analytical instrument (e.g., MS, HPLC).

The Scientist's Toolkit

Table 2: Essential Research Reagent Solutions for Continuous Flow Biocatalysis

| Category | Item | Function/Application |

|---|---|---|

| Immobilization Supports | Isoporous Block Copolymer Membranes (e.g., PS-b-P4VP) | Provides enzyme-matched nanochannels for high-density, oriented immobilization and efficient mass transfer [19]. |

| Epoxy-Functionalized Resins (e.g., Eupergit C) | Enables stable covalent immobilization of enzymes via surface amino groups; widely used in packed beds [1] [18]. | |

| Ni-NTA Agarose/Silica Beads | For affinity immobilization of His-tagged enzymes in packed-bed or microreactor configurations [16]. | |

| Magnetic Nanoparticles (for m-CLEAs) | Facilitates easy recovery and recycling of cross-linked enzyme aggregates using a magnetic field [18]. | |

| Enzyme Engineering Tools | Material Binding Peptides (MBPs, e.g., LCI) | Genetic fusion to enzymes allows for strong, specific, and oriented one-step immobilization onto target surfaces [19]. |

| His-Tag | Standard affinity tag for purification and straightforward immobilization on Ni-NTA functionalized supports [16]. | |

| Critical Reagents | Glutaraldehyde | Bifunctional cross-linker for activating amino-functionalized supports and preparing Cross-Linked Enzyme Aggregates (CLEAs) [1] [18]. |

| Equipment | Function | |

| Syringe/HPLC Pumps | Provides precise and pulseless fluid delivery for continuous flow operation [1]. | |

| Back-Pressure Regulator | Prevents solvent evaporation and gas bubble formation by maintaining pressure above the boiling point of the solvent [1]. | |

| Microfluidic Chips/Capillaries | Serves as the platform for microreactors, offering high surface-to-volume ratios and precise reaction control [16] [17]. |

The pharmaceutical industry faces a dual challenge of reducing its substantial environmental footprint while maintaining economic viability. With global active pharmaceutical ingredient (API) production generating approximately 10 billion kilograms of waste annually at disposal costs of around $20 billion, the imperative for sustainable solutions has never been clearer [21]. Enzyme immobilization techniques integrated with continuous flow systems represent a transformative approach to address these challenges, enabling more efficient, cost-effective, and environmentally friendly manufacturing processes.

This application note details how immobilized enzymes serve as powerful biocatalysts within continuous flow reactors, directly supporting green chemistry principles by minimizing waste, enhancing energy efficiency, and enabling the use of renewable feedstocks [21]. The subsequent sections provide quantitative economic and environmental analysis, detailed experimental protocols for implementation, and a toolkit for researchers to deploy these technologies in drug development pipelines.

Economic and Environmental Impact Analysis

The implementation of immobilized enzyme systems in pharmaceutical manufacturing presents compelling economic and environmental advantages. The data demonstrates significant reductions in both operational costs and environmental impact metrics compared to conventional batch processing with free enzymes.

Table 1: Economic Advantages of Immobilized Enzyme Systems

| Parameter | Free Enzymes (Batch) | Immobilized Enzymes (Continuous Flow) | Improvement |

|---|---|---|---|

| Catalyst Reusability | Single-use | >10 cycles | >60% reduction in enzyme consumption [22] |

| Operational Lifetime | Hours to days | Weeks to months | Enhanced stability under industrial conditions [23] [24] |

| Downstream Processing | Complex separation | Simplified magnetic/recovery | Reduced purification costs [23] |

| Production Format | Batch | Continuous | Higher throughput, smaller footprint [25] |

Table 2: Environmental Impact Assessment

| Environmental Metric | Conventional Chemical Synthesis | Immobilized Enzyme System | Benefit |

|---|---|---|---|

| Energy Consumption | High-temperature/pressure requirements | Mild conditions (30-70°C) | 50% lower energy input [22] |

| Solvent Usage | Organic solvents often required | Aqueous buffers predominant | Reduced hazardous waste [21] |

| Atom Economy | Moderate to low | High | Maximized incorporation into final product [21] |

| Waste Generation | 10 billion kg annually from API production | Significant reduction through reusability | Lower disposal costs and environmental impact [21] |

The economic analysis reveals that immobilized enzymes reduce biocatalyst costs by over 60% through enhanced durability and reusability, directly addressing the high production costs that often impede enzyme adoption in industrial settings [26] [22]. Furthermore, continuous flow systems with immobilized enzymes demonstrate 35% lower energy demands and 40-60% reductions in water usage compared to conventional methods, creating a compelling environmental case alongside economic benefits [22].

Experimental Protocols for Enzyme Immobilization

Protocol 1: Covalent Immobilization on Silica Supports

Principle: Silica-based supports provide mechanical strength, chemical stability, and cost efficiency for pharmaceutical applications [27]. The protocol leverages surface silanol groups that can be functionalized for covalent enzyme attachment, preventing enzyme leakage and enabling repeated use.

Materials:

- DAVISIL silica resin (Grace) with appropriate pore size (recommended: 12-30nm for most enzymes)

- Enzyme solution (1-10 mg/mL in appropriate buffer)

- (3-Aminopropyl)triethoxysilane (APTES) for surface functionalization

- Glutaraldehyde solution (2.5% v/v in buffer)

- Coupling buffer (e.g., 0.1 M phosphate buffer, pH 7.0-8.5)

- Washing solutions (buffer, 1 M NaCl, deionized water)

Procedure:

- Support Activation: Suspend 1g silica resin in 20mL of 5% APTES solution in toluene. Reflux for 6h at 80°C with stirring. Wash extensively with toluene, methanol, and coupling buffer.

- Glutaraldehyde Activation: Transfer activated resin to 20mL of 2.5% glutaraldehyde in coupling buffer. Incubate 2h at room temperature with gentle agitation. Wash with coupling buffer to remove excess glutaraldehyde.

- Enzyme Immobilization: Add glutaraldehyde-activated resin to enzyme solution (1:10 ratio). Incubate for 12-24h at 4°C with continuous mixing.

- Washing and Storage: Wash sequentially with coupling buffer, 1M NaCl, and final storage buffer. Quantify immobilization yield by measuring protein concentration before and after immobilization.

- Quality Control: Determine enzyme activity using standard assays. Store at 4°C in appropriate buffer until use.

Technical Notes: Optimal pH during immobilization is enzyme-specific. Avoid phosphate buffers with amino groups if using glutaraldehyde chemistry. Monitor enzyme-to-support ratio to prevent overcrowding and mass transfer limitations [5] [27].

Protocol 2: Immobilization on Magnetic Nanoparticles (MNPs)

Principle: Magnetic nanoparticles enable rapid separation and recovery in continuous flow systems using external magnetic fields, simplifying downstream processing and enabling catalyst reuse [23] [24].

Materials:

- Magnetic nanoparticles (Fe₃O₄, 10-50nm diameter)

- APTES for surface amination

- Glutaraldehyde or other crosslinkers

- Enzyme solution in appropriate buffer

- Magnetic separation equipment

- Coupling buffers

Procedure:

- MNP Functionalization: Suspend 500mg Fe₃O₄ nanoparticles in 50mL ethanol with 5% APTES. Sonicate for 30min, then stir for 12h at room temperature.

- Washing: Recover amino-functionalized MNPs magnetically. Wash 3x with ethanol and 3x with coupling buffer.

- Crosslinker Attachment: Resuspend MNPs in 2.5% glutaraldehyde solution. Incubate 2h at room temperature with agitation.

- Enzyme Coupling: Add activated MNPs to enzyme solution. Incubate 4-12h at 4°C with continuous mixing.

- Recovery and Storage: Separate immobilized enzyme magnetically. Wash thoroughly until no protein detected in supernatant. Store in appropriate buffer at 4°C.

Technical Notes: MNP size affects surface area and magnetic response. Use functionalized MNPs immediately after preparation. Optimize enzyme loading to balance activity and potential aggregation [23].

Protocol 3: Entrapment in Polymeric Matrices

Principle: Enzyme entrapment within porous polymers protects from denaturation while allowing substrate and product diffusion, particularly useful for multi-enzyme systems in flow reactors [5].

Materials:

- Alginate, polyacrylamide, or silica sol-gel precursors

- Enzyme solution

- Crosslinking agents (CaCl₂ for alginate)

- Syringe pump or droplet generator

- Reaction buffers

Procedure:

- Polymer-Enzyme Mixing: Gently mix enzyme solution with polymer precursor to achieve homogeneous distribution.

- Bead Formation: Extrude polymer-enzyme mixture through syringe needle or droplet generator into crosslinking solution.

- Curing: Allow beads to cure in crosslinking solution for 1-2h.

- Washing and Storage: Wash beads thoroughly with reaction buffer. Store at 4°C until use.

Technical Notes: Control bead size for optimal flow characteristics in reactor systems. Polymer concentration affects pore size and mass transfer rates [5].

Implementation in Continuous Flow Systems

The integration of immobilized enzymes into continuous flow reactors represents a significant advancement in process intensification for pharmaceutical manufacturing. The schematic below illustrates a generalized workflow for implementing these systems:

System Optimization Parameters:

- Flow Rate: Balance between conversion efficiency and residence time

- Temperature: Typically 30-70°C, optimized for enzyme stability and activity

- Reactor Configuration: Fixed-bed for high productivity, fluidized-bed for viscous substrates

- Monitoring: Real-time analysis of product formation and enzyme activity decay

Continuous flow systems with immobilized enzymes demonstrate distinctive catalytic properties, enabling more sustainable and efficient processes [25]. These systems are particularly valuable in pharmaceutical applications where consistent product quality and minimized downstream processing are critical.

The Scientist's Toolkit: Research Reagent Solutions

Successful implementation of immobilized enzyme technologies requires careful selection of support materials and reagents. The following table details key solutions for pharmaceutical applications:

Table 3: Essential Research Reagents for Enzyme Immobilization

| Material Category | Specific Examples | Key Properties | Pharmaceutical Application |

|---|---|---|---|

| Silica Supports | DAVISIL resins, porous silica nanoparticles | High mechanical strength, chemical stability, tunable pore size | Covalent immobilization for continuous flow API synthesis [27] |

| Magnetic Nanoparticles | Fe₃O₄ nanoparticles, amino-functionalized MNPs | Superparamagnetic properties, easy separation, high surface area | Simplified catalyst recovery in batch and flow systems [23] [24] |

| Carbon-Based Materials | Carbon nanotubes, graphene oxide | High surface area, electrical conductivity, functionalization capacity | Biosensor development, specialized biocatalysis [23] |

| Polymeric Matrices | Alginate, polyacrylamide, chitosan | Mild encapsulation conditions, biocompatibility, tunable porosity | Protection of sensitive enzymes, multi-enzyme systems [5] |

| Metal-Organic Frameworks | ZIF-8, MIL-100(Fe) | Extremely high surface area, ordered porous structures | Enhanced enzyme stability under extreme conditions [23] [24] |

| Crosslinkers | Glutaraldehyde, genipin, dextran polyaldehyde | Biocompatibility, specific functional group targeting | Covalent attachment to supports, cross-linked enzyme aggregates [5] |

Troubleshooting and Technical Considerations

Despite the significant advantages, several technical challenges require attention during implementation:

Mass Transfer Limitations: High enzyme loading densities can restrict substrate and product diffusion, reducing apparent activity. Solution: Use porous supports with optimized pore size (typically 2-10× the enzyme diameter) and consider convective flow designs [23].

Enzyme Leaching: Non-covalent immobilization methods may result in enzyme loss over time. Solution: Employ covalent binding strategies with appropriate crosslinkers and optimize binding chemistry for each enzyme-support combination [23] [5].

Activity Reduction: Immobilization can sometimes decrease specific activity due to conformational changes or steric hindrance. Solution: Control enzyme orientation during immobilization, maintain optimal enzyme-to-support ratio, and employ site-specific immobilization techniques [5].

Scale-up Challenges: Reproducibility and uniformity during large-scale production can be problematic. Solution: Develop standardized protocols, implement quality control measures, and consider automated production systems [23].

Enzyme immobilization represents a strategic imperative for the pharmaceutical industry, simultaneously addressing economic pressures and environmental responsibilities. The protocols and data presented demonstrate that immobilized enzyme systems in continuous flow reactors can reduce biocatalyst costs by over 60% while significantly minimizing waste generation and energy consumption [22]. As the industry moves toward more sustainable manufacturing paradigms, these technologies offer a practical pathway to align pharmaceutical production with green chemistry principles while maintaining economic viability. The integration of advanced materials like functionalized silica supports and magnetic nanoparticles with continuous processing creates opportunities for innovation across the drug development pipeline, from initial API synthesis to final product manufacturing.

A Practical Guide to Immobilization Techniques and Their Industrial Applications

This application note provides a detailed overview of three primary carrier-based enzyme immobilization techniques—covalent binding, adsorption, and ionic interactions—within the context of continuous flow research. Enzyme immobilization is a critical engineering strategy for enhancing biocatalyst stability, enabling reuse, simplifying downstream processing, and facilitating continuous operation in biomanufacturing and drug development [28] [10]. We summarize the characteristics of each method, present structured performance data, and provide detailed experimental protocols to guide researchers in selecting and optimizing the appropriate immobilization strategy for their specific application. The integration of these immobilized enzyme systems into continuous flow reactors significantly improves process control, reliability, and potential for automation, thereby advancing sustainable and efficient biocatalytic synthesis [3] [29].

Enzyme immobilization is defined as the confinement of an enzyme to a phase different from that of the substrates and products, typically a solid support or carrier [28] [10]. This confinement enhances the enzyme's stability under operational conditions, allows for its repeated use, and facilitates easy separation from the reaction mixture, which is particularly advantageous for continuous flow processes [5] [10]. In continuous flow biocatalysis, immobilized enzymes are packed into reactors, enabling a continuous substrate feed and product output. This setup minimizes enzyme loss, improves reaction control, and can help overcome challenges like substrate or product inhibition [3] [29].

The choice of immobilization method profoundly impacts the performance, stability, and kinetic properties of the final biocatalyst. Carrier-based methods rely on the physical or chemical attachment of enzymes to a solid support material. An ideal support should be hydrophilic, inert, biocompatible, mechanically stable, and cost-effective [10]. The three techniques discussed herein—covalent binding, adsorption, and ionic interactions—differ primarily in the nature of the enzyme-carrier attachment, which in turn dictates the strength of binding, risk of enzyme leakage, and potential for enzyme activity loss [28] [5] [10].

Comparative Analysis of Immobilization Methods

The following table provides a quantitative comparison of the key characteristics of covalent binding, adsorption, and ionic interaction immobilization methods.

Table 1: Comparative Analysis of Carrier-Based Immobilization Methods

| Parameter | Covalent Binding | Adsorption | Ionic Interactions |

|---|---|---|---|

| Binding Force | Strong covalent bonds [30] | Weak physical forces (Hydrophobic, van der Waals, H-bonding) [5] [31] | Electrostatic attraction [5] |

| Binding Strength | Very High | Low to Moderate | Moderate to High |

| Risk of Enzyme Leaching | Very Low [30] | High [5] | Moderate (Depends on ionic strength) [29] |

| Impact on Enzyme Activity | Potential activity loss due to conformational changes [5] | Minimal conformational change [5] | Minimal conformational change [31] |

| Stability & Reusability | Excellent operational stability & high reusability [30] | Low to moderate reusability due to leaching [31] | Good reusability, sensitive to buffer pH/ion strength [29] |

| Procedure Complexity & Cost | Complex, requires activated supports & longer time [31] | Simple, rapid, and low-cost [5] [31] | Relatively simple and low-cost [5] |

| Common Support Materials | Epoxy-activated resins (e.g., Eupergit), CNBr-activated Sepharose, functionalized nanomaterials [28] [30] [32] | Polypropylene Accurel EP-100, mesoporous silica, carbon nanotubes, coconut fibers [28] [10] | Diethylaminoethyl (DEAE)-based carriers, chitosan, cationic polymers [29] |

| Ideal Application | Continuous-flow processes requiring long-term stability [30] [3] | Single-batch reactions or sensitive enzymes | Multi-enzyme cascades, cofactor immobilization [29] |

Methodologies and Experimental Protocols

Covalent Binding

Principle: This method involves the formation of stable, irreversible covalent bonds between functional groups on the enzyme surface (e.g., amino, carboxyl, thiol) and chemically reactive groups on the support material [28] [30]. This multi-point attachment often leads to a significant reduction in enzyme leaching and can confer heightened stability, particularly against temperature and organic solvents [30].

Diagram: Covalent Binding Immobilization Workflow

Protocol: Covalent Immobilization on Epoxy-Activated Support

This protocol describes the covalent immobilization of an enzyme onto epoxy-activated sepharose beads, a widely used support for its high density of reactive epoxide groups [28] [30].

Research Reagent Solutions:

| Reagent/Material | Function/Description |

|---|---|

| Epoxy-Activated Sepharose 6B | Support matrix providing epoxy functional groups for covalent linkage [28]. |

| Immobilization Buffer (e.g., 0.1 M Carbonate Buffer, pH 8.5) | Provides optimal alkaline pH for nucleophilic attack on epoxy ring by enzyme residues [30]. |

| Target Enzyme Solution | Purified enzyme dissolved in immobilization buffer. |

| Blocking Solution (1 M Ethanolamine, pH 8.0) | Quenches unreacted epoxy groups post-immobilization to prevent non-specific binding [30]. |

| Washing Buffers (e.g., High-Salt, Low-Salt, and Reaction Buffer) | Removes physically adsorbed enzyme and stabilizes the final preparation [28]. |

Step-by-Step Procedure:

- Support Pre-equilibration: Weigh out 1 gram of dry epoxy-activated sepharose. Hydrate and wash it with 50 mL of distilled water followed by 50 mL of immobilization buffer (0.1 M Carbonate, pH 8.5) on a sintered glass filter.

- Enzyme Coupling: Transfer the washed support to a 15 mL conical tube. Add 10 mL of enzyme solution (2-10 mg/mL in immobilization buffer). Gently mix the suspension on a rotary shaker or roller for 16-24 hours at 25°C.

- Washing: After incubation, transfer the suspension back to the filter and wash extensively with at least 50 mL of immobilization buffer to remove any unbound protein.

- Blocking: To block any remaining epoxy groups, incubate the support with 10 mL of 1 M ethanolamine (pH 8.0) for 4-6 hours at room temperature. This step is crucial to deactivate the support and ensure a stable, non-reactive final product.

- Final Wash and Storage: Wash the immobilized enzyme preparation sequentially with 50 mL of high-salt buffer (e.g., 1 M NaCl), 50 mL of low-salt buffer, and finally with the storage or reaction buffer. The final product can be stored as a 50% slurry in an appropriate buffer at 4°C.

Activity Assessment: Determine the activity of the immobilized enzyme and the wash fractions. Calculate immobilization yield and efficiency based on the difference between offered and recovered activity/protein [10].

Adsorption

Principle: Immobilization by adsorption relies on weak, non-covalent physical interactions between the enzyme and the surface of the support material. These interactions include hydrophobic forces, van der Waals forces, and hydrogen bonding [5] [31]. Its main advantage is simplicity and the absence of harsh chemical treatments, which helps preserve native enzyme activity.

Diagram: Adsorption Immobilization Workflow

Protocol: Hydrophobic Adsorption on Polymeric Carriers

This protocol utilizes a hydrophobic carrier like polypropylene Accurel EP-100, which is highly effective for adsorbing enzymes like lipases, often leading to hyperactivation by opening the active site lid [28].

Research Reagent Solutions:

| Reagent/Material | Function/Description |

|---|---|

| Accurel EP-100 (Polypropylene) | Macroporous hydrophobic support for enzyme adsorption [28]. |

| Equilibration Buffer (e.g., 10 mM Phosphate Buffer, pH 7.0) | Provides ionic strength and pH control for optimal enzyme binding. |

| Target Enzyme Solution | Enzyme dissolved in equilibration buffer. |

| Washing Buffer (Same as Equilibration Buffer) | Removes unbound enzyme without desorbing the immobilized fraction. |

Step-by-Step Procedure:

- Support Preparation: Weigh 1 gram of Accurel EP-100. Pre-wet and equilibrate it by incubating in 20 mL of equilibration buffer for 1 hour.

- Enzyme Adsorption: Drain the buffer from the support. Add 10 mL of enzyme solution (1-5 mg/mL in the same buffer) to the damp support. Ensure the suspension is homogeneous.

- Incubation: Incubate the mixture for 1-2 hours at room temperature with gentle stirring or shaking. Prolonged incubation or vigorous agitation should be avoided to prevent enzyme denaturation.

- Washing and Recovery: Filter the suspension under mild vacuum. Gently wash the immobilized enzyme with 20-30 mL of equilibration buffer to remove any unabsorbed enzyme.

- Storage: The prepared biocatalyst can be used immediately or stored as a damp cake at 4°C for short-term use.

Activity Assessment: The activity of the adsorbed enzyme is highly dependent on the support's properties and the enzyme's surface characteristics. Monitor the wash fractions for protein content to estimate binding capacity. Assess activity retention by comparing the activity of the immobilized catalyst to an equivalent amount of free enzyme.

Ionic Interactions

Principle: This method is based on the reversible electrostatic attraction between charged amino acid residues on the enzyme's surface and oppositely charged groups on the support material [5] [29]. It is widely used for cofactor immobilization, enabling efficient enzyme-cofactor recycling in continuous-flow systems [29].

Diagram: Ionic Interaction Immobilization Workflow

Protocol: Immobilization via Ionic Adsorption on DEAE-Cellulose

This protocol uses Diethylaminoethyl (DEAE)-cellulose, an anion-exchange support bearing positively charged groups, to immobilize an enzyme with a net negative charge at a pH above its isoelectric point (IEP) [29].

Research Reagent Solutions:

| Reagent/Material | Function/Description |

|---|---|

| DEAE-Cellulose | Anion-exchange support with positively charged diethylaminoethyl groups [29]. |

| Equilibration Buffer (e.g., 10 mM Tris-HCl, pH 8.0) | Low ionic strength buffer at a pH above the enzyme's IEP to ensure enzyme is negatively charged. |

| Target Enzyme Solution | Enzyme dissolved in equilibration buffer. |

| Washing Buffer (Same as Equilibration Buffer) | Removes unbound enzyme. |

Step-by-Step Procedure:

- Charge Determination: Determine the isoelectric point (IEP) of the target enzyme. Select an equilibration buffer with a pH at least 1 unit above the IEP to ensure the enzyme carries a net negative charge.

- Support Equilibration: Weigh 1 gram of DEAE-Cellulose. Swell and equilibrate it by washing with 50 mL of equilibration buffer on a sintered glass filter.

- Enzyme Binding: Transfer the equilibrated support to a tube. Add 10-15 mL of enzyme solution. Gently agitate the mixture for 1-2 hours at 4°C to maximize binding and minimize denaturation.

- Washing: Filter the suspension and wash with equilibration buffer until the absorbance of the washate at 280 nm is negligible.

- Storage: Store the immobilized enzyme as a slurry in equilibration buffer at 4°C. Avoid using high-ionic-strength buffers, which can disrupt the ionic bonds and cause enzyme leaching.

Activity Assessment: Measure the activity of the immobilized enzyme preparation. The binding efficiency is highly sensitive to pH and ionic strength. Conduct immobilization experiments across a range of pH and conductivity values to optimize the binding capacity and retained activity.

Application in Continuous Flow Systems

The integration of carrier-immobilized enzymes into continuous flow reactors is a cornerstone of modern biocatalysis, particularly for pharmaceutical synthesis [3]. Covalently immobilized enzymes are ideally suited for packed-bed reactors (PBRs) due to their minimal leakage, which ensures long-term operational stability and consistent product quality over extended periods [30] [3]. Adsorbed enzymes can be used in flow but may be more suitable for single-batch reactions or shorter processes due to leaching risks. Systems based on ionic interactions are highly valuable for complex cofactor-dependent reactions, where both the enzyme and the costly cofactor (e.g., NAD+) can be co-immobilized and retained within the reactor, enabling efficient in-situ cofactor regeneration [29].

Key advantages for flow chemistry include:

- Enhanced Mass Transfer: The constant flow of substrate solution past the immobilized enzyme improves mixing and reduces diffusion limitations compared to batch systems [3].

- Precise Process Control: Parameters such as residence time, temperature, and pressure can be tightly regulated, leading to higher reproducibility and yield [3] [29].

- Automation and Scalability: Continuous flow systems are inherently easier to automate and scale up, either by numbering-up (using multiple reactors in parallel) or scaling-out [3].

Troubleshooting Guide

Table 2: Common Issues and Recommended Solutions

| Problem | Possible Cause | Suggested Solution |

|---|---|---|

| Low Immobilization Yield | Support pore size too small for enzyme diffusion. | Use a support with larger pore diameter (>2x enzyme size) [10]. |

| Low Retained Activity (Covalent) | Harsh coupling conditions denaturing the enzyme. | Use a milder activation chemistry (e.g., epoxy instead of CNBr) or introduce a spacer arm [28] [30]. |

| Enzyme Leaching (Adsorption/Ionic) | Weak binding strength; changes in pH/ionic strength. | Optimize buffer conditions. Switch to covalent binding for critical applications [5] [29]. |

| Diffusion Limitation / Low Reaction Rate | High enzyme loading causing pore blockage. | Reduce enzyme loading or use a non-porous or macroporous support to improve substrate access [10]. |

| Reduced Stability in Flow Reactor | Mechanical shear or pressure compression. | Choose a mechanically rigid support (e.g., controlled-pore glass) suitable for PBRs [10]. |

The advancement of enzyme immobilization techniques is pivotal for developing efficient, stable, and reusable biocatalytic systems, particularly for continuous flow manufacturing in pharmaceutical and fine chemical synthesis [33] [3]. Immobilization enhances enzyme stability, facilitates catalyst recovery, and enables continuous processing, thereby reducing operational costs and improving sustainability [22] [5]. The selection of an appropriate support material is critical as it directly influences the catalytic performance, operational stability, and economic viability of the immobilized enzyme system. Among the diverse range of carrier materials, Metal-Organic Frameworks (MOFs), natural polymers, and inorganic carriers have emerged as particularly promising due to their unique structural and chemical properties. These advanced materials offer high surface areas, tunable porosity, and excellent biocompatibility, making them ideal for creating robust biocatalysts suited for the demanding conditions of continuous flow reactors [34] [35] [36].

The integration of these immobilized enzymes into continuous flow systems represents a paradigm shift in biomanufacturing, enabling enhanced reaction control, improved productivity, and simplified downstream processing [3] [19]. This application note provides a detailed examination of MOFs, natural polymers, and inorganic carriers, offering structured quantitative comparisons, detailed experimental protocols, and visual workflows to support researchers in selecting, synthesizing, and applying these advanced materials within their enzyme immobilization projects.

Quantitative Comparison of Advanced Support Materials

The table below summarizes the key characteristics, performance metrics, and applications of the three primary classes of advanced support materials.

Table 1: Comparative Analysis of Advanced Support Materials for Enzyme Immobilization

| Material Class | Specific Examples | Key Advantages | Typical Enzyme Loading | Operational Stability | Primary Applications |

|---|---|---|---|---|---|

| Metal-Organic Frameworks (MOFs) | NU-1000, ZIF-8, HKUST-1, MIL-series, UIO-series [34] [36] | Ultra-high surface area, tunable pore size, crystalline structure, protective microenvironment [34] [36] | Up to 173 μg enzyme/mg MOF (for EST2 in NU-1000) [34] | 30-fold increased stability reported for EST2@NU-1000 in flow [34] | CO2 conversion (e.g., using CA, FDH) [36], continuous flow biocatalysis in aqueous & organic solvents [34] |

| Natural Polymers | Chitosan, Alginate, Sodium Alginate [35] [5] | Biocompatibility, biodegradability, low toxicity, low cost, easily functionalized [35] [5] | High loading capacity (e.g., 63.5-79.77% for protease in mesoporous silica/zeolite) [5] | Good stability in mild aqueous conditions; dependent on cross-linking [5] | Drug delivery, biosensors, food processing, entrapment/encapsulation [35] [5] |

| Inorganic Carriers | Silica Nanoparticles, Magnetic Nanoparticles (MNPs), Gold Nanoparticles (AuNPs) [35] | High chemical/thermal stability, high mechanical strength, ease of functionalization (e.g., SiO2), magnetic separation (MNPs) [35] | High due to high surface area (e.g., silica nanoparticles) [35] | Enhanced stability against denaturation (e.g., in mesoporous silica) [35] | Biofuel production, biosensing, biomedical applications, continuous flow membrane reactors [19] [35] |

Detailed Experimental Protocols

Protocol 1: Enzyme Immobilization in MOFs via Post-Synthetic Infiltration

This protocol describes the immobilization of the esterase EST2 from Alicyclobacillus acidocaldarius into the MOF NU-1000 for use in a continuous flow reactor, achieving a 30-fold stability enhancement and record space-time yields [34].

Research Reagent Solutions

- NU-1000 MOF: Synthesized and activated according to established literature procedures [34].

- Enzyme Solution: Purified AaEST2 esterase (≥98%) in Tris-buffered saline (TBS: 150 mM Tris, 150 mM NaCl, pH 7.4).

- Substrate Solution: 3 mM 4-nitrophenyl acetate (pNPA) in TBS.

- HPLC Column Reactor: Empty HPLC column capable of being packed with solid support.

Methodology

- MOF Activation: Ensure NU-1000 powder is fully activated and solvent-free prior to use.

- Enzyme Loading (Infiltration):

- Immerse the activated NU-1000 powder (5 mg) in a solution of AaEST2 esterase in TBS buffer.

- Allow the mixture to incubate with gentle agitation. Loading kinetics typically show a rapid decrease in supernatant enzyme concentration within the first 5 minutes, reaching near-maximum loading (e.g., 170-173 μg enzyme per mg MOF) within several hours [34].

- Recover the Enzyme@MOF composite via centrifugation and wash gently with TBS to remove any superficially adsorbed enzyme.

- Reactor Packing: Pack the AaEST2@NU-1000 composite into an HPLC column. The remaining space in the column can be filled with inert silica to minimize dead volume [34].

- Continuous Flow Operation:

- Integrate the packed column reactor into an HPLC system or similar flow setup.

- Pump the substrate solution (3 mM pNPA in TBS) through the reactor at a controlled flow rate (e.g., up to 1 mL/min).

- Monitor product formation (4-nitrophenol) online via UV-Vis detection.

- The reactor achieves a high space-time yield of 1432 g L⁻¹ h⁻¹ and maintains operational stability over extended periods [34].

Protocol 2: Fabrication of an Enzymatic Membrane Reactor with Block Copolymer Membranes

This protocol details the creation of a high-performance enzymatic flow reactor using a pore-size matching block copolymer (BCP) membrane and a genetically fused material-binding peptide for oriented enzyme immobilization [19].

Research Reagent Solutions

- PS-b-P4VP Membrane: Asymmetric isoporous block copolymer membrane (e.g., polystyrene-block-poly(4-vinyl pyridine)) fabricated via evaporation-induced self-assembly and non-solvent-induced phase separation (SNIPS) [19].

- Engineered Enzyme: Phytase from Yersinia mollaretii (YmPh) genetically fused with the Material Binding Peptide (MBP) LCI (YmPh-LCI).

- Immobilization Buffer: Appropriate aqueous buffer (e.g., phosphate or Tris buffer) at ambient temperature.

Methodology

- Membrane Preparation: Fabricate or procure the isoporous BCP membrane. The membrane should feature a cylindrical top layer with uniform, enzyme-matched nanochannels (~57.5 nm diameter) and a macroporous spongy sublayer [19].

- Enzyme Immobilization:

- Prepare a solution of the engineered YmPh-LCI fusion protein.

- Incubate the BCP membrane with the YmPh-LCI solution under optimized conditions to allow for oriented one-step immobilization via the MBP. This results in a homogeneous enzyme monolayer with a high surface coverage of >80% and a binding capacity of ~830 pmol cm⁻² [19].

- Reactor Assembly and Operation:

- Assemble the enzyme-functionalized membrane into a suitable flow cell module.

- Pump the substrate solution (e.g., phytate) through the membrane reactor in a single-pass continuous flow process.

- The nanoconfined environment of the matching pores enables efficient mass transfer, yielding exceptional catalytic performance with operational stability exceeding one month and a space-time yield of up to 1.05 × 10⁵ g L⁻¹ d⁻¹ [19].

Protocol 3: Surface Functionalization of Inorganic Carriers for Covalent Immobilization

This protocol outlines a general strategy for covalently attaching enzymes to inorganic carriers like silica or magnetic nanoparticles, which enhances enzyme stability and prevents leaching [35] [5].

Research Reagent Solutions

- Functionalized Inorganic Carrier: Silica nanoparticles or Magnetic Iron Oxide Nanoparticles (MNPs), surface-functionalized with amino, epoxy, or carboxyl groups.

- Coupling Agent: Glutaraldehyde (for amine-functionalized supports) or a carbodiimide reagent like EDC (1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide) for carboxyl-functionalized supports.

- Enzyme Solution: Target enzyme in a compatible buffer (e.g., phosphate buffer, pH 7.0-7.5).

- Washing Buffers: Preparation buffer followed by a buffer containing a quenching agent (e.g., Tris buffer to quench unreacted aldehyde groups).

Methodology

- Support Activation:

- For amine-functionalized carriers, incubate with a glutaraldehyde solution (e.g., 2.5-5% v/v) for 1-2 hours to introduce aldehyde groups. Wash thoroughly to remove excess glutaraldehyde.

- For carboxyl-functionalized carriers, activate with a solution of EDC (and often NHS, N-Hydroxysuccinimide) to form an active ester intermediate.

- Enzyme Coupling:

- Incubate the activated carrier with the enzyme solution for several hours (2-24 hours) at room temperature or 4°C with gentle agitation.

- The enzyme's surface amino groups (lysine residues) will form Schiff bases with aldehyde groups or amide bonds with activated carboxyl groups.

- Quenching and Washing:

- After coupling, quench any remaining active groups. For glutaraldehyde-activated supports, use a Tris buffer or a reducing agent like sodium borohydride to reduce Schiff bases to stable secondary amines.

- Wash the immobilized enzyme preparation extensively with buffer to remove any non-covalently bound enzyme.

- Storage and Use: The covalently immobilized enzymes can be stored in buffer at 4°C and used in either batch or packed-bed continuous flow reactors. The covalent attachment ensures minimal enzyme leakage during operation [35] [5].

Visual Experimental Workflows

Workflow for MOF-Based Enzyme Immobilization

The following diagram illustrates the primary strategies for immobilizing enzymes within Metal-Organic Frameworks.

MOF Immobilization Pathways

Workflow for Nanoengineered Carrier Immobilization

This diagram outlines the key decision points and steps involved in immobilizing enzymes on various nanoengineered materials.

Nanocarrier Selection and Immobilization

Application Notes for Continuous Flow Research

The integration of immobilized enzymes into continuous flow systems presents unique advantages and considerations for each class of support material.

MOFs in Flow Reactors: Enzyme@MOF composites are exceptionally well-suited for packed-bed continuous flow reactors. Their crystalline structure and tunable porosity not only protect the enzyme but also control the transport of reactants and products, leading to dramatically increased space-time yields. For instance, a MOF-based continuous flow enzyme reactor has demonstrated a 10-fold higher space-time yield compared to other immobilization strategies [34]. This makes MOFs ideal for multi-step syntheses and reactions in both aqueous and organic solvents.

Membrane-Based Flow Systems: Block copolymer membranes with engineered, enzyme-matched nanochannels represent a cutting-edge approach to continuous flow biocatalysis. The key advantage lies in the pore-size matching, which minimizes mass transfer limitations and creates a nanoconfined environment that can enhance catalytic performance. These systems enable single-pass, high-throughput processing with exceptional long-term operational stability, making them highly attractive for industrial-scale applications [19].

Magnetic Nanoparticles for Simplified Processing: In both batch and flow configurations, magnetic nanoparticles (MNPs) offer the distinct advantage of facile catalyst recovery. Using an external magnetic field, the immobilized enzymes can be rapidly separated from the reaction mixture for reuse. This simplifies downstream processing and significantly enhances the sustainability and cost-effectiveness of the biocatalytic process [35]. In flow systems, MNPs can be used in magnetically stabilized beds to combine continuous operation with easy catalyst replacement.

The Scientist's Toolkit: Essential Research Reagents

Table 2: Key Research Reagent Solutions for Enzyme Immobilization

| Reagent / Material | Function / Description | Example Use Case |

|---|---|---|

| NU-1000 MOF | A mesoporous metal-organic framework with large pores suitable for enzyme infiltration [34]. | Host for esterase EST2 in continuous flow reactors for organic synthesis [34]. |

| PS-b-P4VP Membrane | An isoporous block copolymer membrane with uniform, enzyme-sized nanochannels [19]. | Carrier for oriented immobilization of phytase via material-binding peptides in a high-performance flow reactor (NaMeR) [19]. |

| Material Binding Peptide (MBP) LCI | A genetically fused peptide tag that enables strong, oriented binding to specific material surfaces [19]. | Used to create YmPh-LCI fusion for precise, high-coverage immobilization on PS-b-P4VP membranes [19]. |

| Functionalized Silica Nanoparticles | Inorganic carriers offering high surface area and easily modified surface chemistry (e.g., with amino or epoxy groups) [35]. | Covalent immobilization of various enzymes (e.g., lipases, proteases) for enhanced stability in batch and flow systems [35] [5]. |

| Magnetic Nanoparticles (MNPs) | Iron oxide cores (e.g., Fe₃O₄) coated with silica or polymers, functionalized for enzyme binding [35]. | Facile separation and recycling of immobilized enzymes using an external magnetic field [35]. |

| Chitosan | A natural, biodegradable, and biocompatible polymer with amino groups for enzyme attachment [35] [5]. | Matrix for enzyme encapsulation or as a coating composite for other nanomaterials [35]. |

Within the broader context of developing efficient enzyme immobilization techniques for continuous flow research, carrier-free immobilization strategies have emerged as a superior alternative to traditional carrier-bound methods. These approaches eliminate the non-catalytic mass of a support material, thereby yielding biocatalysts with significantly higher volumetric activity and productivity [37] [38]. Among these, Cross-Linked Enzyme Aggregates (CLEAs) and Cross-Linked Enzyme Crystals (CLECs) represent two prominent methodologies. They are particularly valuable for continuous processes due to their enhanced stability, ease of separation, and robustness under operational conditions [18]. This application note provides a detailed overview of their advantages, preparation protocols, and key applications, with a specific focus on their integration into intensified biocatalytic processes.

Comparative Analysis: CLEAs vs. CLECs

The selection of an appropriate carrier-free immobilization method depends on the specific requirements of the biocatalytic process. Table 1 summarizes the core characteristics, advantages, and challenges associated with CLEAs and CLECs.

Table 1: Comparative Analysis of CLEAs and CLECs

| Feature | Cross-Linked Enzyme Aggregates (CLEAs) | Cross-Linked Enzyme Crystals (CLECs) |

|---|---|---|