FACS for Enzyme Evolution: High-Throughput Screening Strategies to Accelerate Protein Engineering

This article provides a comprehensive guide for researchers on implementing Fluorescence-Activated Cell Sorting (FACS) as a high-throughput screening method for directed enzyme evolution.

FACS for Enzyme Evolution: High-Throughput Screening Strategies to Accelerate Protein Engineering

Abstract

This article provides a comprehensive guide for researchers on implementing Fluorescence-Activated Cell Sorting (FACS) as a high-throughput screening method for directed enzyme evolution. We explore the foundational principles of FACS-based screening, detailing critical steps from assay development and library compartmentalization to sorting execution. We address common methodological challenges and optimization strategies for improving signal-to-noise ratio, specificity, and sorting efficiency. Furthermore, we discuss validation protocols to confirm sorted clone functionality and compare FACS with alternative screening platforms like microfluidics and absorbance-based assays. The content is tailored for scientists and drug development professionals seeking to accelerate the discovery and optimization of enzymes for industrial and therapeutic applications.

FACS Screening Fundamentals: Core Principles and Assay Design for Enzyme Libraries

Why FACS? Understanding Throughput, Sensitivity, and Multiplexing Advantages.

Within the paradigm of directed evolution, the ability to screen vast genetic libraries is the primary bottleneck. Fluorescence-Activated Cell Sorting (FACS) has emerged as a preeminent platform for high-throughput screening, enabling the interrogation of >10⁸ variants per day. This application note delineates the core advantages of FACS—throughput, sensitivity, and multiplexing—and provides detailed protocols for its application in evolving enzymes, such as polymerases or proteases, for drug discovery pipelines.

Quantitative Advantages of FACS Screening

Table 1: Comparison of Key Screening Platform Metrics

| Metric | FACS-Based Screening | Microtiter Plate Screening | Microfluidic Droplet Sorting |

|---|---|---|---|

| Throughput (events/day) | >10⁸ | ~10⁴ | ~10⁷ |

| Assay Volume | 50-500 µL (in bulk) | 100-200 µL/well | 1-10 pL/droplet |

| Sensitivity (Molecules) | ~100-1000 fluorescent proteins | ~10⁹ (bulk fluorescence) | ~100-1000 |

| Multiplexing Capacity | High (4-6 parameters typical) | Low (typically 1-2) | Moderate (2-3) |

| Sorting Purity | 85-99% | N/A | 90-99% |

| Library Size Practicality | Very Large (>10⁸) | Small (<10⁴) | Large (10⁷-10⁸) |

Core Protocol 1: FACS-Based Screening for Enhanced Polymerase Activity

Objective: Isolate DNA polymerase variants with increased incorporation rate of reverse-transcriptase substrates (e.g., modified nucleotides) from a displayed library on yeast or phage.

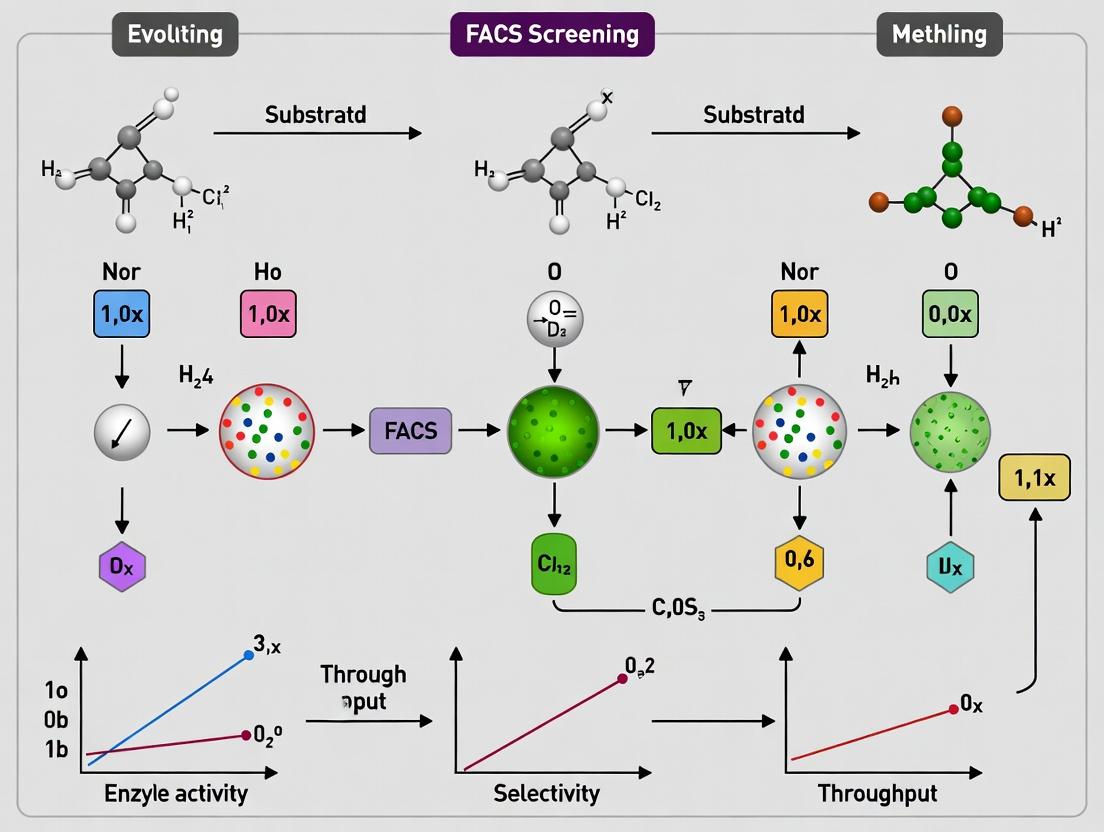

Workflow Diagram Title: FACS Screen for Polymerase Evolution

Reagents and Materials:

- Yeast display vector library: Contains polymerase gene fused to Aga2p surface anchor.

- Fluorogenic nucleotide analogue: e.g., Cy5-dUTP. Polymerase activity incorporates fluorophore.

- Anti-c-MYC Alexa Fluor 488 conjugate: Labels display marker for normalization.

- FACS buffer: PBS pH 7.4, 1% BSA, 1 mM EDTA. Prevents clumping and non-specific binding.

- Growth media (SDCAA/SCGAA): For yeast propagation and induction.

- High-speed cell sorter: e.g., BD FACS Aria III or Sony SH800, equipped with 488nm and 640nm lasers.

Procedure:

- Induction: Grow library to mid-log phase. Induce polymerase expression in SGGCAA media at 20°C for 24-48h.

- Reaction: Harvest 10⁸ cells, wash. Resuspend in 100 µL reaction buffer containing 50 µM Cy5-dUTP and necessary co-factors (Mg²⁺). Incubate at 25°C for 30-60 min.

- Labeling: Quench reaction with ice-cold EDTA buffer. Wash cells. Label surface display marker with anti-c-MYC-AF488 (1:100 dilution) for 30 min on ice.

- Analysis & Gating: Resuspend in 1 mL FACS buffer. Analyze control cells (no substrate, inactive enzyme) to set background fluorescence gate. For the library sample, apply a dual-parameter gate for high AF488 (display) and high Cy5 (activity).

- Sorting: Sort the top 0.1-1% doubly-positive population into a tube containing rich recovery media. Perform 2-4 iterative rounds, progressively tightening gates.

- Recovery & Analysis: Plate sorted cells for single-colony isolation. Sequence plasmids and characterize kinetic parameters of purified variants.

Core Protocol 2: Multiplexed Screening for Protease Substrate Specificity

Objective: Employ a dual-reporter system to simultaneously screen for protease activity and against non-specific cleavage, enhancing specificity.

Diagram Title: Dual-Color Protease Specificity Screening

Reagents and Materials:

- Dual FRET substrate reporters: Cell-permeable peptides with target cleavage sequence (GFP signal) and non-target sequence (RFP signal).

- Protease induction system: E.g., mammalian display or bacterial periplasmic display.

- Flow cytometer with 488nm & 561nm lasers: For detecting GFP and RFP.

- Protease inhibitor cocktail: For negative control samples.

Procedure:

- Stain Library: Induce protease expression. Aliquot library into two tubes. To each, add both FRET substrates (final concentration 5 µM). To one tube, add broad-spectrum protease inhibitor as a no-activity control.

- Incubation: Incubate cells at 37°C for 1-2 hours.

- Wash & Resuspend: Wash cells twice in ice-cold PBS + 0.1% BSA. Resuspend in FACS buffer.

- Gating Strategy: Using the inhibited control, set the baseline for autofluorescence. Create a scatter plot of GFP vs. RFP fluorescence. Set a polygonal gate to select cells with high GFP and low RFP fluorescence.

- Sorting & Validation: Sort the gated population. Isolate clones and validate specificity using kinetic assays with purified substrates.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for FACS-Based Enzyme Evolution

| Item | Function & Rationale |

|---|---|

| Fluorogenic / Fluorogenic Substrates | Directly link enzymatic turnover to a fluorescent signal (hydrolysis, incorporation). Enables real-time activity measurement in single cells. |

| Display System (Yeast, Phage, Bacterial) | Physically links genotype (DNA) to phenotype (enzyme function) for sorting and recovery. |

| Viability Dyes (e.g., PI, 7-AAD) | Excludes dead/damaged cells from analysis, improving sort purity and recovery. |

| Magnetic Beads (for Pre-enrichment) | Can be used to pre-enrich for library members that express the displayed enzyme, increasing screening efficiency. |

| Anti-Tag Fluorescent Antibodies | Labels the display tag for normalization of activity to expression level, critical for gating. |

| Ultra-low Binding Tubes & Plates | Minimizes cell loss during preparation and sorting, crucial for maintaining library diversity. |

| Clone-Conditioned Recovery Media | Enhances post-sort viability of sensitive cells (e.g., yeast, mammalian) for outgrowth. |

This Application Note details the core components of a Fluorescence-Activated Cell Sorting (FACS) screening workflow, contextualized within high-throughput enzyme evolution for drug discovery. We provide protocols and reagent solutions for converting cellular phenotype into quantitative, sortable data, enabling the isolation of improved enzyme variants from vast libraries.

In enzyme evolution, FACS bridges genotype and phenotype by enabling the ultra-high-throughput screening (>10⁷ events/day) of cellular libraries based on fluorescent signals reporting on enzyme activity. This workflow is critical for accelerating the development of biocatalysts for pharmaceutical synthesis and therapeutic targeting.

Core Workflow Components & Quantitative Benchmarks

Table 1: Key Performance Metrics in a Typical FACS Screening Campaign

| Component | Parameter | Typical Range/Benchmark | Impact on Screening |

|---|---|---|---|

| Library Diversity | Initial Variant Pool | 10⁷ – 10⁹ clones | Determines searchable sequence space |

| Cell Preparation | Viability Post-Induction | >90% | Reduces sorting of non-viable events |

| FACS Instrument | Event Rate (Sort Speed) | 10,000 – 30,000 events/sec | Throughput and practical screening time |

| Sort Purity Mode | Yield (Fast) vs. Purity (Precise) | Balances recovery and accuracy | |

| Gating Strategy | Recovery Rate (Enriched Pool) | 0.1% – 5% of total events | Determines stringency and library enrichment |

| Post-Sort Analysis | Fold-Enrichment (vs. Control) | 10 – 1000x | Measures success of a single sort round |

| Clonal Validation | Hit Correlation (Sort vs. Assay) | 70% – 95% | Validates the sorting phenotype |

Detailed Experimental Protocols

Protocol 1: Construction of a Fluorescence-Linked Enzyme Library inE. coli

Objective: Genetically fuse enzyme variants to a fluorescence reporting system (e.g., via substrate conversion to a fluorescent product or transcriptional activation of GFP).

- Library Cloning: Use Golden Gate or USER assembly to clone a mutagenized gene library (e.g., error-prone PCR product) into an appropriate expression vector. The vector must contain:

- An inducible promoter (e.g., pBAD, T7).

- The enzyme gene fused or coupled to the reporter system.

- A selection marker (e.g., ampicillin resistance).

- Transformation: Electroporate the assembled library into competent E. coli cells (e.g., TOP10, BL21). Use large-scale electroporation (multiple cuvettes) to maximize library size.

- Library Expansion: Plate serial dilutions to determine library size. Scrape all transformation plates, pool cells, and incubate in LB + antibiotic for 4-6 hours at 37°C. Add 25% glycerol and freeze 1mL aliquots at -80°C as your master library stock.

Protocol 2: Cell Preparation and Staining for FACS

Objective: Induce enzyme expression and generate a fluorescent signal proportional to activity.

- Induction: Inoculate 1 mL of LB + antibiotic with 10 µL of thawed library stock. Grow overnight (12-16 hrs) at 37°C, 250 rpm. Dilute 1:100 into fresh medium (2 mL) and grow to OD₆₀₀ ~0.6. Add inducer (e.g., 0.2% arabinose) and incubate at optimal expression temperature (often 30°C) for 4-6 hours.

- Signal Development: If using an intracellular fluorogenic substrate, add it to the culture at a predetermined optimal concentration (e.g., 50-200 µM) 30-60 minutes before sorting. For transcriptional reporters, ensure sufficient time for GFP maturation (>45 mins post-induction).

- Harvest & Wash: Pellet 1 mL of culture at 4,000 x g for 3 min. Wash cells twice with 1 mL of ice-cold FACS Buffer (1x PBS, 2 mM EDTA, 0.5% BSA, pH 7.4).

- Resuspension & Filtration: Resuspend final pellet in 0.5-1 mL of ice-cold FACS Buffer. Pass cell suspension through a 35-40 µm cell strainer cap into a FACS tube. Keep on ice and protected from light until sorting.

Protocol 3: FACS Instrument Setup and Sorting

Objective: Configure the sorter to identify and physically isolate cells with desired fluorescence.

- Instrument Startup & QC: Perform instrument startup and quality control using standardized fluorescent beads. Align lasers and adjust time delay for droplet formation.

- Parameter Setup: Create a plot for FSC-A vs. SSC-A to identify the primary bacterial population. Create a histogram for the relevant fluorescence channel (e.g., FITC for GFP).

- Gating Strategy: a. Gate P1 (Singlets): On FSC-H vs. FSC-A plot, gate the population with high correlation to exclude doublets. b. Gate P2 (Live Cells): On FSC-A vs. SSC-A plot, gate the main, healthy bacterial population. c. Gate P3 (Positive Population): On the fluorescence histogram, set a sorting gate based on control samples. Use a non-fluorescent negative control (empty vector) to set the threshold. Use a known positive control (wild-type enzyme) to confirm signal.

- Sorting: Set the sort mode to "Purity" for highest accuracy. Sort the brightest 0.1-1% of cells from the P3 gate into a collection tube containing 500 µL of recovery medium (LB + antibiotic). Keep collection tube on ice.

- Post-Sort Analysis: Run a small aliquot of the sorted sample to verify sort purity. Plate serial dilutions for single colonies and inoculate the remainder in liquid culture for expansion and subsequent sorting rounds or analysis.

Visualization of Workflows

Diagram 1: FACS Screening Workflow for Enzyme Evolution

Diagram 2: Logical Gating Strategy for Hit Isolation

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for FACS-Based Enzyme Screening

| Item | Function & Rationale | Example/Specification |

|---|---|---|

| Fluorogenic Enzyme Substrate | Provides the direct link between enzymatic turnover and fluorescence signal. Must be cell-permeable and non-fluorescent until cleaved. | Coumarin-based esters, fluorescein diacetate (FDA) derivatives, custom quenched substrates. |

| FACS Buffer | Maintains cell viability and prevents clumping during sorting. EDTA chelates divalent cations to reduce aggregation. BSA reduces non-specific binding. | 1x PBS, 2 mM EDTA, 0.5% BSA (w/v), filter sterilized (0.22 µm), pH 7.4. |

| Cell Strainer Caps | Removes cell aggregates and debris critical for preventing nozzle clogging and ensuring accurate single-cell sorting. | 35 µm nylon mesh, pre-sterilized, for 5 mL FACS tubes. |

| Alignment & QC Beads | Verifies instrument laser alignment, fluorescence sensitivity, and sort delay calibration before running precious samples. | Multi-color, multi-intensity bead mix (e.g., Sphero Rainbow beads). |

| Recovery Medium | Provides nutrients and osmotic support for sorted cells to recover from the shear stress of the sorting process. | Rich medium (e.g., LB or SOC) with relevant antibiotic. Pre-warm to 37°C. |

| Expression Vector with Reporter | Genetic construct that co-links the enzyme variant genotype with the fluorescent phenotype. | Plasmid with inducible promoter, enzyme gene, and either a transcriptional GFP reporter or a fused fluorescent protein. |

| Competent Cells | High-efficiency cells for library transformation to maximize diversity capture. | Electrocompetent E. coli (e.g., MC1061, BL21), >10⁹ cfu/µg efficiency. |

Application Notes: Enabling High-Throughput Enzyme Evolution via FACS

This document details the integration of fluorogenic substrates and cellular reporter systems into functional enzyme assays, specifically optimized for Fluorescence-Activated Cell Sorting (FACS) in directed evolution pipelines. The core principle involves coupling enzyme activity to a quantifiable fluorescent signal within a living cell, enabling the screening of vast mutant libraries (10^8–10^9 variants) to isolate variants with enhanced catalytic properties.

Key Design Considerations

- Signal-to-Noise Ratio: The assay must generate a strong, specific fluorescence signal from productive catalysis against low cellular autofluorescence and non-specific substrate hydrolysis. Typical successful assays achieve a minimum 10- to 100-fold increase in median fluorescence intensity (MFI) between active and inactive enzyme populations.

- Cellular Permeability & Compatibility: Substrates or their precursors must be cell-permeable and non-toxic. The assay must function within the physiological context (pH, redox potential, competing activities) of the host cell (e.g., E. coli, yeast, mammalian cells).

- Kinetic Range: The assay's dynamic range must be sensitive enough to discriminate between subtle improvements in enzyme kinetics (kcat/KM). Data from recent implementations show that FACS can reliably enrich variants with as little as a 1.5- to 2-fold improvement in activity per sorting round.

Quantitative Performance Metrics of Common Systems

Table 1: Comparison of Fluorogenic Substrate & Reporter Systems for FACS

| System Type | Example Substrate/Reporter | Typical Signal Gain (Active/Inactive) | Time to Readout (Post-Induction) | Compatibility with Common Hosts | Primary Readout |

|---|---|---|---|---|---|

| Hydrolytic Enzyme Substrate | Fluorescein diacetate (FDA) | 50-100x | 30 min - 2 hrs | E. coli, Yeast, Mammalian | Intracellular fluorescence (Green) |

| Protease Substrate | Cell-permeable peptide-AMC derivative | 20-50x | 1 - 4 hrs | Mammalian, Yeast | Free fluorophore (Blue/UV) |

| Transcriptional Reporter | Enzyme product activates GFP transcription | 100-1000x | 4 - 12 hrs | E. coli, Yeast | GFP expression (Green) |

| Bimolecular Fluorescence Complementation (BiFC) | Enzyme activity reconstitutes split-YFP | 10-30x | 6 - 24 hrs | Mammalian, Yeast | Reconstituted YFP (Yellow) |

| FRET-Based Reporter | Cleavable linker between CFP and YFP | 5-15x (Ratio change) | 2 - 6 hrs | Mammalian | CFP/YFP Emission Ratio |

Protocols

Protocol 1: Direct Intracellular Assay with Fluorogenic Substrates

Objective: To screen a library of hydrolytic enzymes (e.g., esterases, phosphatases) using a cell-permeable, non-fluorescent substrate that yields a fluorescent product upon enzymatic cleavage.

Materials:

- Library: E. coli cells expressing enzyme variants from an inducible plasmid.

- Substrate: Fluorescein diacetate (FDA), stock solution 10 mM in DMSO.

- Buffers: PBS (pH 7.4), LB medium with appropriate antibiotics.

- Equipment: Flow cytometer equipped with a 488 nm laser and 530/30 nm bandpass filter.

Procedure:

- Culture & Induction: Grow 1 mL cultures of library clones in deep-well plates to mid-log phase (OD600 ~0.6). Induce enzyme expression with appropriate inducer (e.g., 0.1 mM IPTG) for 2 hours at 30°C.

- Substrate Loading: Harvest cells by centrifugation (3000 x g, 3 min). Wash once with PBS. Resuspend cells in PBS containing 10 µM FDA (from 10 mM DMSO stock). Final DMSO concentration should not exceed 0.1%.

- Incubation: Incubate the cell suspension in the dark at room temperature for 30 minutes with gentle shaking.

- Quenching & Preparation: Pellet cells, wash once with ice-cold PBS to remove external substrate and fluorescein. Resuspend in ice-cold PBS at a density of ~107 cells/mL. Keep on ice and protected from light.

- FACS Analysis & Sorting: Analyze cells using a 488 nm laser. Gate on the healthy cell population based on forward/side scatter. Set the sorting gate on the top 0.1-5% of the population exhibiting the highest fluorescence in the FITC/GF channel (530/30 nm). Collect sorted cells into recovery media for expansion and subsequent rounds of sorting/analysis.

Protocol 2: Transcriptional Reporter Assay for Metabolizing Enzymes

Objective: To screen for enzyme activity that produces a metabolite capable of activating a transcription factor, leading to GFP expression. Ideal for oxidoreductases, transferases, or lyases.

Materials:

- Two-Plasmid System: (1) Enzyme expression plasmid (inducible), (2) Reporter plasmid with metabolite-responsive promoter driving GFPmut3.

- Buffers & Media: LB with dual antibiotics, PBS.

- Equipment: Flow cytometer with 488 nm laser.

Procedure:

- Strain Preparation: Co-transform the enzyme library and the reporter plasmid into the host E. coli strain. Plate on dual-antibiotic media.

- Culture & Induction: Pick colonies into deep-well plates containing 1 mL media. Grow to OD600 ~0.5. Induce enzyme expression with a sub-saturating concentration of inducer to maintain a correlation between activity and signal.

- Reporter Development: Allow 8-12 hours post-induction for the metabolite to accumulate, transcription factor activation, and GFP maturation.

- Sample Preparation: Dilute cultures 1:100 in PBS. Keep on ice.

- FACS Sorting: Analyze cells using standard GFP settings. Gate on the brightest 0.1-2% of cells based on GFP fluorescence. Sort directly into rich media for outgrowth. Include a control strain with an inactive enzyme to set the baseline fluorescence gate.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for FACS-Based Enzyme Assay Development

| Item | Function & Key Consideration |

|---|---|

| Cell-Permeable Fluorogenic Substrates (e.g., FDG, CMFDA, AMC derivatives) | Provide the direct link between catalysis and fluorescence. Must have low background hydrolysis and high permeability. |

| Fluorescent Protein Reporter Plasmids (e.g., GFP, YFP, mCherry under inducible/const. promoters) | Enable construction of transcriptional or translational fusion reporters. Variants with fast maturation are preferred. |

| Flow Cytometry Calibration Beads (e.g., rainbow calibration particles) | Essential for standardizing instrument performance and ensuring day-to-day sorting consistency. |

| Microfluidic Cell Sorter Chips or Nozzle Assemblies | Consumables for the sorter. Size must be matched to the cell type (e.g., 100 µm nozzle for E. coli). |

| High-Efficiency Electrocompetent Cells (e.g., NEB 10-beta, TG1) | For high-efficiency library transformation to ensure maximum representation of variants. |

| Next-Generation Sequencing (NGS) Library Prep Kits | For post-sort analysis of enriched populations to identify beneficial mutations and track library diversity. |

Visualizations

Diagram 1: High-Throughput Enzyme Evolution via FACS Screening Workflow

Diagram 2: Direct Intracellular Fluorogenic Assay Mechanism

Diagram 3: Transcriptional Reporter Assay Signaling Pathway

In high-throughput enzyme evolution, particularly when coupled with Fluorescence-Activated Cell Sorting (FACS) screening, the choice of host organism is a critical determinant of success. This application note outlines the key considerations, quantitative benchmarks, and practical protocols for utilizing Escherichia coli, yeast (primarily Saccharomyces cerevisiae), and mammalian cells (e.g., HEK293, CHO) as expression hosts. The context is the engineering of enzymes for therapeutic and industrial applications, where FACS enables the isolation of rare, improved variants from vast libraries.

Host System Comparison: Quantitative Analysis

Table 1: Key Characteristics of Host Systems for Enzyme Expression & FACS Screening

| Feature | E. coli | Yeast (S. cerevisiae) | Mammalian Cells (HEK293) |

|---|---|---|---|

| Typical Growth Time | 1-3 hours (doubling) | 1.5-2 hours (doubling) | 18-24 hours (doubling) |

| Expression Timeline | 4-24 hours post-induction | 24-72 hours | 48-96 hours (transient) |

| Cost per Liter Culture | $1 - $10 | $10 - $50 | $500 - $2000 |

| Typical Yield (Soluble Protein) | 10-100 mg/L | 1-50 mg/L | 0.1-10 mg/L (transient) |

| Post-Translational Modifications | Limited (no glycosylation, limited disulfides) | Core glycosylation, disulfide bonds | Human-like (complex glycosylation, phosphorylation) |

| Library Size Capacity | 10^9 - 10^11 | 10^7 - 10^9 | 10^6 - 10^8 |

| FACS Compatibility | High (robust, small size) | High (robust, slightly larger) | Moderate (more fragile, requires gentle handling) |

| Key Advantage | Speed, cost, high library diversity | Eukaryotic secretion & folding, fairly simple | Authentic human PTMs, functional activity assays |

| Primary Limitation | Lack of eukaryotic PTMs, protein aggregation | Lower transformation efficiency than E. coli | Cost, time, technical complexity |

Table 2: FACS Screening Parameters by Host

| Parameter | E. coli | Yeast | Mammalian Cells |

|---|---|---|---|

| Common FACS Reporter | Intracellular fluorescence, surface display (e.g., Aga2p fusion) | Surface display (Aga1p-Aga2p), secreted enzyme capture | Surface display (e.g., pDisplay vector), secreted enzyme capture |

| Typical Sorting Rate | 20,000-50,000 events/sec | 10,000-30,000 events/sec | 5,000-15,000 events/sec |

| Critical Buffer | PBS + 0.5-1 mM EDTA | PBS + 1 mM EDTA + 0.5% BSA | DPBS + 1% FBS + 25 mM HEPES |

| Post-Sort Viability | >80% | >70% | 50-80% (process-dependent) |

| Sorting Temperature | 4°C | 4°C or RT | 4°C (strict) |

Experimental Protocols

Protocol 1: FACS-Based Screening of anE. coliSurface-Displayed Enzyme Library

Objective: To isolate enzyme variants with enhanced catalytic activity from an E. coli library displayed via an outer membrane protein (e.g., Lpp-OmpA scaffold).

Materials:

- Genetically encoded fluorogenic substrate (e.g., a non-fluorescent substrate that yields a fluorescent product upon enzymatic cleavage).

- FACS buffer: Phosphate-buffered saline (PBS), pH 7.4, 0.5 mM EDTA, 0.1% (w/v) glucose.

- FACS sorter equipped with a 488 nm laser and appropriate emission filters.

Procedure:

- Library Induction: Grow E. coli library to mid-log phase (OD600 ~0.6-0.8). Induce expression of the surface-displayed enzyme fusion with 0.1-0.5 mM IPTG for 16-18 hours at 25°C.

- Cell Harvest: Pellet 1 mL of culture at 4,000 x g for 5 min at 4°C. Wash cells twice with 1 mL of ice-cold FACS buffer.

- Activity Labeling: Resuspend cells in 500 µL FACS buffer containing the fluorogenic substrate at a predetermined optimal concentration. Incubate in the dark at room temperature for 30-60 minutes with gentle agitation.

- Quenching & Preparation: Pellet cells, wash once with 1 mL ice-cold FACS buffer to stop the reaction. Resuspend in 1 mL ice-cold FACS buffer and pass through a 35 µm cell strainer.

- FACS Sorting: Set gates on forward/side scatter to exclude debris and aggregates. Identify the top 0.1-1% of cells exhibiting the highest fluorescence intensity (e.g., FITC channel). Sort these cells into sterile microcentrifuge tubes containing 500 µL of rich recovery medium (e.g., 2xYT).

- Recovery & Expansion: Immediately plate sorted cells onto selective agar plates or inoculate into small liquid cultures for expansion and subsequent analysis or sorting rounds.

Protocol 2: Yeast Surface Display FACS Screening for Affinity Maturation

Objective: To screen a yeast surface-displayed enzyme library for variants with altered binding affinity to a target ligand.

Materials:

- Biotinylated target ligand.

- Streptavidin-conjugated fluorophore (e.g., Alexa Fluor 647).

- Anti-c-Myc antibody (FITC conjugate) for display level detection.

- FACS buffer: PBS, pH 7.4, 1 mM EDTA, 0.5% (w/v) bovine serum albumin (BSA).

Procedure:

- Induction: Induce expression of the Aga2p-enzyme fusion protein in the yeast library by transferring cells to SG-CAA medium (for the pYD1 vector system) and incubating at 20-25°C for 18-24 hours.

- Labeling: Harvest 1-5 x 10^7 cells by centrifugation. Wash once with PBSA (PBS + 0.1% BSA).

- Primary Labeling: Incubate cells with a range of concentrations of biotinylated ligand in PBSA for 1 hour on ice or at room temperature. Include a negative control with no ligand.

- Secondary Labeling: Wash cells twice with PBSA to remove unbound ligand. Incubate with streptavidin-Alexa Fluor 647 (SA-647) and anti-c-Myc-FITC in PBSA for 20-30 minutes on ice in the dark.

- Washing & Preparation: Wash cells twice with PBSA, resuspend in 1 mL ice-cold FACS buffer, and filter through a 35 µm strainer.

- FACS Gating & Sorting: Gate on single cells. Create a 2D plot of FITC (display level) vs. Alexa Fluor 647 (binding). Gate to select cells with high 647 fluorescence normalized to FITC fluorescence (high binding/display ratio). This corrects for expression level variations. Sort the top population.

- Recovery: Sort cells directly into SD-CAA medium. Allow to recover at 30°C for 1-2 days before plasmid isolation or subsequent sorts.

Protocol 3: Mammalian Cell Transient Transfection & Secreted Enzyme Capture for FACS

Objective: To screen a mammalian cell library secreting a glycosylated enzyme, using a cell-surface capture assay compatible with FACS.

Materials:

- PEI-Max transfection reagent.

- Capture reagent: A biotinylated anti-enzyme antibody or a biotinylated substrate analogue.

- Streptavidin-PE.

- Live/Dead viability dye (e.g., Zombie NIR).

- FACS buffer: DPBS + 1% Fetal Bovine Serum (FBS) + 25 mM HEPES.

Procedure:

- Library Transfection: Seed HEK293T cells in a 6-well plate at 70% confluence. Co-transfect the enzyme library DNA (e.g., in a secretory signal-containing vector) with a transfection reagent per manufacturer's protocol. Include a GFP-expressing plasmid (5-10% of total DNA) to monitor transfection efficiency.

- Expression: 6 hours post-transfection, replace medium with fresh, serum-free or low-serume medium. Incubate for 48-72 hours to allow enzyme secretion.

- Cell-Surface Capture: Gently dissociate cells using enzyme-free dissociation buffer. Wash once with DPBS.

- Viability Staining: Resuspend cells in DPBS containing a 1:1000 dilution of Zombie NIR viability dye. Incubate for 15 minutes in the dark at RT. Wash with 2 mL of FACS buffer.

- Enzyme Capture & Labeling: Incubate cells with the biotinylated capture reagent (1-10 µg/mL) in FACS buffer for 60 minutes on ice. Wash twice. Then incubate with Streptavidin-PE (1:200 dilution) for 30 minutes on ice in the dark.

- FACS Sorting: Wash cells, filter, and resuspend in 1 mL FACS buffer. Gate on single, live (viability dye negative), GFP-positive (transfected) cells. Sort the top 1-5% of cells based on PE signal (captured enzyme).

- Recovery: Sort cells directly into pre-warmed complete medium in a collagen-coated plate or flask. Allow to recover for 48 hours before plasmid rescue (if using an episomal system) or passaging.

Visualizations

Title: Host System Selection Decision Tree

Title: Generic High-Throughput FACS Screening Workflow

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for FACS-Based Enzyme Evolution

| Reagent/Category | Example Product/Type | Function in Experiment |

|---|---|---|

| Fluorogenic Substrates | 4-Methylumbelliferyl (4-MU) derivatives; Fluorescein diacetate (FDA) analogues. | Provides a direct, enzyme-activity-dependent fluorescent readout for FACS gating. Cell-permeable pro-fluorophores become fluorescent upon enzymatic cleavage. |

| Surface Display Scaffolds | E. coli: Lpp-OmpA, INP. Yeast: Aga1p-Aga2p system (pYD1 vector). Mammalian: pDisplay vector. | Anchors the enzyme library to the cell surface, allowing interaction with extracellular substrates or ligands and linkage of genotype to phenotype. |

| Viability Dyes | Propidium Iodide (PI); Zombie dyes (Fixable Viability Dyes). | Distinguishes live from dead cells during FACS, preventing the sorting of non-viable cells which would not recover. Critical for mammalian cell sorts. |

| Cell Strainers | 35 µm or 40 µm nylon mesh strainers. | Removes cell clumps and aggregates prior to FACS to prevent nozzle clogging and ensure accurate single-cell sorting. |

| FACS Sheath Fluid & Buffer | Isotonic, sterile-filtered PBS or DPBS; Commercial FACS sort buffer (e.g., with BSA, EDTA). | Maintains cell viability and osmotic balance during sorting. Reduces cell clumping. Specific buffers are optimized for each host type. |

| Episomal/Recovery Vectors | E. coli: pUC-based high-copy plasmids. Yeast: CEN/ARS plasmids. Mammalian: EBV-based oriP/EBNA1 vectors. | Allows for efficient plasmid rescue from sorted cell populations, enabling sequence analysis and iterative library construction. |

| Transfection Reagents | PEI-Max, Lipofectamine 3000, electroporation kits. | Enables efficient, high-throughput introduction of DNA libraries into host cells, especially critical for yeast and mammalian systems. |

In high-throughput enzyme evolution, particularly when using Fluorescence-Activated Cell Sorting (FACS), linking enzymatic activity to a fluorescent signal is paramount. This linkage enables the screening of vast genetic libraries (10^6–10^9 variants) to isolate improved biocatalysts. The core challenge lies in designing a robust molecular "wire" that translates the chemical event (e.g., bond cleavage or formation) into a quantifiable fluorescence change detectable by FACS. This application note details two fundamental wiring strategies—Direct and Indirect Reporting—contrasting their mechanisms, implementation protocols, and applications within a FACS screening pipeline.

The choice between direct and indirect reporting fundamentally shapes screen sensitivity, generality, and background signal.

Direct Fluorescence Reporting

This strategy employs substrates that are intrinsically fluorogenic. Enzyme action directly alters the fluorescent properties of the substrate molecule itself.

- Mechanism: The substrate is typically a non-fluorescent or quenched molecule that, upon enzymatic conversion, yields a highly fluorescent product. Common mechanisms include dequenching (e.g., FRET substrate cleavage), photoinduced electron transfer (PeT) quenching relief, or generation of a fluorophore from a pro-fluorophore.

- Advantages: Simpler molecular design, single-component system, minimal background, and a direct 1:1 relationship between fluorescence intensity and reaction rate.

- Disadvantages: Requires custom chemical synthesis of fluorogenic substrates for each enzyme target, limiting generality. The substrate structure may not perfectly mimic the natural substrate.

Indirect Fluorescence Reporting

This strategy decouples the enzymatic reaction from fluorescence generation by using a secondary, generic reporter system that is modulated by the enzyme's product.

- Mechanism: The enzyme reaction generates a product that is detected by a secondary component (e.g., a transcription factor, a coupling enzyme, or a binding protein), which in turn activates a fluorescent reporter. Common systems include transcription factor-based biosensors (e.g., for sugars, acids, or hormones) or enzyme-coupled assays (e.g., NAD(P)H generation linked to a dehydrogenase).

- Advantages: Highly generalizable; a single biosensor can report on any enzyme producing its specific ligand. Allows the use of natural, non-fluorogenic substrates.

- Disadvantages: Multi-component system requiring co-expression or delivery. Increased risk of false positives from bypass mutations. Signal amplification can lead to non-linear kinetics and higher background.

Table 1: Quantitative Comparison of Direct vs. Indirect Reporting Strategies

| Parameter | Direct Reporting | Indirect Reporting |

|---|---|---|

| Typical Signal-to-Background (S/B) Ratio | 10 – 1000+ | 2 – 50 |

| Library Throughput (cells/sortable) | Up to 10^9 | 10^7 – 10^8 |

| Development Time | Long (substrate synthesis) | Short (biosensor engineering) |

| Substrate Generality | Low (target-specific) | High (product-specific) |

| Key Risk | Non-native substrate kinetics | Sensor crosstalk/ false positives |

| Best For | Hydrolases, phosphatases, specific oxidoreductases | Metabolic enzymes, kinases, polymerases, broad substrate panels |

Detailed Experimental Protocols

Protocol 1: Direct Reporting for a Esterase/Lipase using a Fluorogenic Acetate Ester

Objective: To sort an esterase library using the direct, fluorogenic substrate fluorescein diacetate (FDA). Materials: E. coli library expressing esterase variants, Fluorescein Diacetate (FDA, 10 mM stock in DMSO), PBS/M9 Buffer (pH 7.4), FACS sorting buffer (PBS + 0.1% Pluronic F-108). Procedure:

- Induction & Expression: Grow library cultures to mid-log phase, induce enzyme expression (e.g., with IPTG) for 2-4 hours at 30°C.

- Cell Preparation: Harvest cells by centrifugation (3,000 x g, 5 min). Wash twice with ice-cold PBS. Resuspend at ~10^7 cells/mL in FACS buffer.

- Substrate Loading: Add FDA to the cell suspension at a final concentration of 50 µM. Mix gently.

- Incubation & Reaction: Incubate the mixture at room temperature for 30 minutes in the dark. Enzyme activity hydrolyzes FDA to release fluorescent fluorescein, which is retained inside cells with intact membranes.

- FACS Analysis & Sorting: Immediately analyze on a FACS sorter (e.g., excitation 488 nm, emission 530/30 nm bandpass filter). Gate on the top 0.1-1% of the fluorescence population. Sort positive cells into recovery media.

- Recovery & Validation: Grow sorted cells, isolate plasmids, and re-test individual clones in microplate assays with FDA to confirm enhanced activity.

Protocol 2: Indirect Reporting for a Kinase using a Transcription Factor Biosensor

Objective: To sort a tyrosine kinase library using a genetically encoded biosensor for ATP depletion/ADP generation. Materials: E. coli library co-expressing kinase variants and the ADP-responsive biosensor (e.g., ribosome-binding ADP sensor Riboglow), non-fluorogenic kinase substrate peptide, 1 mM ATP stock, M9 minimal medium. Procedure:

- Dual Expression: Co-transform or construct a bicistronic operon for kinase and biosensor expression. Grow in selective medium.

- Sensor Equilibration: Induce full sensor expression first. Ensure basal fluorescence is stable (requires 2-4 hours).

- Kinase Reaction Initiation: Add the kinase substrate peptide (100 µM) and ATP (200 µM) to the cell suspension in M9 medium. Incubate with shaking for 60-90 mins.

- Signal Development: As the kinase consumes ATP, increasing ADP levels activate the biosensor, leading to increased fluorescence (e.g., GFP variant).

- FACS Analysis & Sorting: Analyze cells using appropriate laser/filter sets for the biosensor fluorophore (e.g., 488 nm ex / 510 nm em for GFP). Sort the brightest fluorescent population (indicative of high ADP/kinase activity).

- Counter-Screening: Re-screen sorted clones in a secondary assay (e.g., phospho-specific antibody stain) to eliminate false positives that activate the biosensor without phosphorylating the target substrate.

Visualizing Signaling Pathways and Workflows

Diagram 1: Direct Fluorescence Reporting Pathway

Diagram 2: Indirect Fluorescence Reporting Pathway

Diagram 3: FACS Screening Workflow for Enzyme Evolution

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Fluorescence-Linked Enzyme Screening

| Item | Function & Relevance | Example Product/Category |

|---|---|---|

| Fluorogenic Substrates | Direct reporters; become fluorescent upon enzyme action. Critical for hydrolases, proteases. | Fluorescein diacetate (FDA), AMC/GFC coumarin derivatives, Resorufin esters. |

| FRET-Quenched Peptides | Direct reporters for proteases; cleavage separates fluorophore/quencher. | Peptides with DABCYL/EDANS or QSY/CF dye pairs. |

| Transcription Factor Biosensors | Indirect reporters; genetically encoded sensors for metabolites (sugars, acids, ions). | Allosteric transcription factors (e.g., LacI, TetR) fused to GFP. |

| Riboswitch-Based Sensors | Indirect reporters; RNA-based sensors that regulate GFP translation in response to ligands. | ADP- or amino acid-binding riboswitch-GFP fusions. |

| Enzyme-Coupled Assay Kits | Indirect reporters; uses a secondary enzyme to generate a fluorescent product from the primary enzyme's output. | NAD(P)H detection kits coupled to dehydrogenase assays. |

| Cell-Permeant Ester Substrates | Enable substrate loading into live cells for intracellular enzyme screening. | Acetoxymethyl (AM) ester derivatives of fluorescent indicators. |

| FACS-Compatible Buffers | Maintain cell viability and prevent clumping during sort. Contain mild surfactants and energy sources. | PBS with 0.1-1% BSA or Pluronic F-68, EDTA-free. |

| Microfluidic Droplet Generation Oil | For ultra-high-throughput screening via droplet-based FACS (dFACS). | Fluorinated oil with biocompatible surfactants (e.g., PEG-PFPE). |

Building Your FACS Pipeline: A Step-by-Step Protocol for Enzyme Evolution

Application Notes

The success of high-throughput FACS screening for enzyme evolution is fundamentally dependent on the initial generation of a high-quality library where each cell contains only one gene variant. This one-gene-per-cell principle is critical for establishing a clear genotype-phenotype link, enabling accurate sorting and subsequent hit identification. Transformation and compartmentalization methods are the primary gatekeepers of this fidelity. Inefficient or uncontrolled transformation leads to multiple plasmids per cell, confounding screening results and drastically reducing effective library diversity. The following notes and protocols detail optimized strategies for achieving high-efficiency, single-variant transformation within the context of a FACS-based enzyme evolution workflow.

Key Considerations:

- Transformation Efficiency vs. Library Coverage: The transformation efficiency must exceed the theoretical library diversity by at least 10-fold to ensure adequate representation of all variants. For a library of 10^9 unique clones, >10^10 transformants are targeted.

- Compartmentalization via Emulsion: Water-in-oil emulsion (w/o) droplet generation physically isolates individual genes and expression machinery, ensuring that transcribed proteins (the phenotype) remain linked to their encoding DNA (the genotype). This is especially crucial for in vitro screening systems like droplet-based FACS (e.g., Drop-seq, microfluidic sorting).

- Host Strain Selection: The choice of E. coli or yeast strain directly impacts transformation efficiency, expression levels, and folding of the target enzyme. Strains with disabled recombinase systems (e.g., E. coli DH10B, SS320) are preferred to maintain plasmid and insert stability.

Quantitative Benchmarks for Library Construction

| Parameter | Target Value | Typical Range | Measurement Method |

|---|---|---|---|

| Transformation Efficiency (E. coli) | >1 x 10^9 CFU/µg | 5 x 10^8 – 5 x 10^9 CFU/µg | Serial dilution plating |

| Single-Variant Rate | >95% | 90-99% | Colony PCR / Sequencing |

| Plasmid Copies/Cell | 1 - 10 (low copy) | 1 - 20 | qPCR of plasmid vs. genomic DNA |

| Emulsion Droplet Diameter | 20 - 50 µm | 10 - 100 µm | Microscopy / Particle analyzer |

| Droplet Occupancy (λ) | 0.1 - 0.3 | 0.05 - 0.5 | Poisson distribution calculation |

| Library Coverage (N/ diversity) | >10x | 10x - 100x | (Total CFU) / (Theoretical Diversity) |

Detailed Protocols

Protocol 1: High-Efficiency ElectrocompetentE. coliPreparation & Transformation for Single-Variant Libraries

Objective: To generate electrocompetent cells capable of achieving >10^9 CFU/µg transformation efficiency with a high percentage of cells harboring a single plasmid.

Materials:

- E. coli strain (e.g., DH10B, TG1).

- LB broth and agar plates with appropriate antibiotic.

- SOC Outgrowth Medium.

- GYT Medium (10% glycerol, 0.125% yeast extract, 0.25% tryptone).

- Sterile, ice-cold 10% Glycerol.

- Plasmid DNA library (highly purified, eluted in nuclease-free water or 10 mM Tris-HCl).

- Electroporation cuvettes (1 mm gap).

- Electroporator.

Procedure:

- Cell Growth: Inoculate 5 mL of LB with a single colony and grow overnight (16-18 hrs) at 37°C, 250 rpm.

- Dilution & Log-Phase Growth: Dilute the overnight culture 1:100 into 250 mL of fresh LB in a 2 L flask. Grow at 37°C, 250 rpm until OD600 reaches 0.5-0.6 (~2.5-3 hrs).

- Chilling: Immediately place the flask on ice for 30 mins. Swirl periodically. All subsequent steps are performed at 0-4°C with pre-chilled solutions and centrifuge rotors.

- Harvesting: Pellet cells at 4,500 x g for 15 mins at 4°C. Decant supernatant thoroughly.

- Washing: Gently resuspend pellet in 250 mL of ice-cold sterile water. Centrifuge at 4,500 x g for 15 mins. Decant. Repeat wash with 125 mL of ice-cold water.

- Glycerol Wash: Resuspend pellet in 50 mL of ice-cold 10% glycerol. Centrifuge at 4,500 x g for 15 mins.

- Final Resuspension: Resuspend pellet in 1-2 mL of ice-cold 10% glycerol (final volume ~2.5 mL). Aliquot 50-100 µL into pre-chilled microcentrifuge tubes. Flash-freeze in liquid nitrogen and store at -80°C.

- Electroporation: Thaw an aliquot on ice. Mix 1 µL of plasmid library DNA (1-100 ng) with 50 µL of competent cells. Transfer to a pre-chilled 1 mm electroporation cuvette. Electroporate (e.g., 1.8 kV, 200Ω, 25µF). Immediately add 950 µL of pre-warmed SOC medium, transfer to a culture tube, and recover at 37°C, 250 rpm for 1 hour.

- Plating & Assessment: Plate serial dilutions on selective agar to calculate transformation efficiency. Use the remainder for library amplification or direct screening.

Protocol 2: Water-in-Oil Emulsion Compartmentalization for Single-Cell Encapsulation

Objective: To generate monodisperse water-in-oil droplets containing, on average, less than one cell (λ < 0.3) to ensure single-cell, single-variant compartmentalization.

Materials:

- Aqueous Phase: Cell suspension in growth medium or PCR mix.

- Oil Phase: Surfactant-containing oil (e.g., Fluorinated oil with 2% PEG-PFPE surfactant for fluorosurfactants, or mineral oil with 4% Abil EM 90 for non-fluorinated systems).

- Microfluidic droplet generation device (e.g., Flow-focusing PDMS chip) or syringe-based mechanical homogenizer.

- Syringe pumps and gas-tight syringes.

- Microscope for droplet inspection.

Procedure (Microfluidic):

- Sample Preparation: Dilute the transformed cell suspension to a target concentration (e.g., 1-5 x 10^6 cells/mL) based on the Poisson distribution to achieve λ = 0.1-0.3. Load into a gas-tight syringe.

- Oil Phase Preparation: Load surfactant-oil mixture into a separate gas-tight syringe.

- Device Priming: Connect syringes to the inlets of a clean, hydrophobic microfluidic chip via tubing. Prime the chip with oil to fill all channels.

- Droplet Generation: Set syringe pumps to appropriate flow rates. Typical rates: Continuous phase (oil) at 1000-2000 µL/hr, Dispersed phase (aqueous cell mix) at 200-500 µL/hr. Monitor droplet formation at the flow-focusing junction. Adjust flow rates to achieve stable generation of monodisperse droplets of desired size (20-50 µm).

- Collection: Collect emulsion in a PCR tube or glass vial on ice. Proceed to incubation (for cell growth/expression) or direct injection into a droplet-compatible FACS sorter.

Poisson Calculation for Occupancy (λ): λ = (Cell Concentration (cells/mL)) * (Droplet Volume (mL)) Example: For 50 µm diameter droplets (Volume ≈ 6.5 x 10^-8 mL) and a cell concentration of 3 x 10^6 cells/mL, λ ≈ 0.2. This means ~82% of occupied droplets contain exactly 1 cell, ~16% are empty, and ~2% contain >1 cell.

Visualizations

Title: Single-Variant Library Prep & Droplet Workflow

Title: Droplet Occupancy at λ=0.2

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Library Transformation/Compartmentalization |

|---|---|

| Ultra-Pure Plasmid Prep Kits | Ensures high-quality, endotoxin-free DNA for maximum electroporation efficiency. |

| Electrocompetent E. coli Strains (e.g., NEB 10-beta, Lucigen EC100) | Genetically engineered for high transformation efficiency (>10^9 CFU/µg) and stable plasmid maintenance. |

| Recovery Media (SOC, TB) | Nutrient-rich, non-selective media for outgrowth post-electroporation to maximize cell viability. |

| Fluorinated Oil & Surfactants (e.g., 3M Novec 7500, Ran Biotech Surfactants) | Forms stable, biocompatible, and inert water-in-oil emulsions compatible with microfluidics and FACS. |

| Microfluidic Droplet Chips (PDMS or Glass) | Generates highly monodisperse droplets for precise single-cell compartmentalization. |

| Droplet Generation Oil (e.g., Bio-Rad Droplet Generation Oil) | Ready-to-use oil phase for ddPCR or droplet-based workflows, ensuring consistent performance. |

| Cell Stains & Viability Dyes (e.g., SYTO dyes, CFSE, Propidium Iodide) | Enables monitoring of cell concentration, viability, and encapsulation efficiency prior to screening. |

| Droplet Readout Reagents | Fluorogenic enzyme substrates or affinity beads co-encapsulated to generate a selectable phenotype within each droplet. |

Within a high-throughput enzyme evolution pipeline utilizing Fluorescence-Activated Cell Sorting (FACS), the critical step linking genetic diversity to selectable function is the physical display of enzymes on the microbial cell surface. The efficiency of this display is governed by the induction and expression conditions of the display system (e.g., yeast, phage, or bacterial). Suboptimal expression leads to low display levels, poor enzymatic activity, or cellular stress, resulting in false negatives during FACS screening and a failure to isolate truly improved variants. This protocol details the systematic optimization of induction parameters for functional enzyme display on Saccharomyces cerevisiae via the Aga2p anchoring system, a cornerstone methodology for directed evolution of enzymes like lipases, esterases, and peroxidases.

Optimal induction is a balance between maximizing display density and maintaining cell viability and enzymatic function. The following table summarizes key variables and their typical optimized ranges based on current literature and standard practices.

Table 1: Key Induction Parameters for Yeast Surface Display Optimization

| Parameter | Tested Range | Optimized Value/Range | Impact on Display & Function |

|---|---|---|---|

| Induction Temperature | 18°C - 30°C | 20°C - 25°C | Lower temps improve folding of complex enzymes; >30°C increases misfolding. |

| Induction Time | 2 - 48 hours | 12 - 24 hours | Display saturates ~18-24h; longer times can lead to proteolysis or cell lysis. |

| Inducer Concentration (Galactose) | 0.01% - 4% (w/v) | 0.5% - 2.0% (w/v) | Titratable; high concentrations (>2%) can induce stress responses. |

| Initial OD600 at Induction | 0.5 - 10.0 | 0.8 - 1.5 | Critical for aeration and nutrient availability during protein production. |

| Media pH | 5.0 - 7.5 | 6.0 - 6.5 (buffered) | Maintains consistent cellular metabolism and display stability. |

| Supplemental Additives | N/A | 1-2mM EDTA, 0.1-1mM PMSF | Protease inhibitors minimize displayed enzyme degradation. |

Detailed Protocol: Optimizing Induction for Yeast Surface Display

Objective: To determine the optimal induction conditions for displaying a functional enzyme on the yeast surface to maximize signal in subsequent FACS-based activity screens.

Part A: Preparatory Culture

- Transformation & Selection: Transform S. cerevisiae EBY100 strain with the pCTCON2 vector encoding your enzyme-Aga2p fusion. Select transformants on SD-CAA plates (glucose, lacking tryptophan). Incubate at 30°C for 48-72 hours.

- Inoculum: Pick a single colony into 5 mL of SD-CAA medium. Incubate at 30°C, 250 rpm, for 16-20 hours (to saturation, OD600 >5).

Part B: Induction Culture Setup (Multi-Condition Test)

- Dilution: Dilute the saturated culture to OD600 = 0.5 in pre-warmed SD-CAA. Grow at 30°C, 250 rpm, until OD600 reaches 0.8-1.0 (~2-3 hours).

- Induction: Pellet cells (3000 x g, 2 min). Resuspend cell pellets to OD600 = 1.0 in SG-CAA (galactose) induction media pre-equilibrated to the target temperatures.

- Test Grid: Set up cultures varying: Temperature (20°C, 25°C, 30°C) and Galactose concentration (0.1%, 0.5%, 2.0%). Use 5 mL cultures in baffled flasks.

- Induction Phase: Incubate cultures with shaking (250 rpm) for the determined induction period (e.g., 24 hours). Sample 1 mL aliquots at 6, 12, 18, and 24 hours for analysis.

Part C: Analysis of Display and Function

- Display Check (Flow Cytometry):

- Pellet 100 µL of induced culture (5000 x g, 1 min).

- Wash once with PBSA (PBS + 0.5% BSA).

- Label with primary anti-c-Myc antibody (1:100 dilution in PBSA) for 30 min on ice.

- Wash twice, then label with Alexa Fluor 488-conjugated secondary antibody (1:200) for 30 min on ice in the dark.

- Wash twice, resuspend in PBSA, and analyze by flow cytometry. Mean Fluorescence Intensity (MFI) indicates display level.

- Functional Assay (Substrate Conversion):

- For fluorogenic substrates (e.g., fluorescein diacetate for esterases), incubate 100 µL of cells with substrate in assay buffer.

- Monitor fluorescence increase over time via plate reader or flow cytometry. Activity is proportional to the rate of fluorescence generation per cell.

- Viability Check: Perform a propidium iodide (PI) stain (1 µg/mL final concentration, 5 min incubation) and analyze by flow cytometry. The percentage of PI-negative cells indicates viability.

Part D: Data-Driven Optimization

- Plot Display MFI, Specific Activity (MFI activity/Display MFI), and % Viability for each condition and time point.

- The optimal condition is that which maximizes the product of Display MFI and Specific Activity while maintaining viability >85%.

Visualizing the Optimization Workflow and Cellular Pathway

Diagram Title: Optimization Workflow for Yeast Surface Display

Diagram Title: GAL1 Induction Pathway for Yeast Display

The Scientist's Toolkit: Essential Reagent Solutions

Table 2: Key Research Reagents for Display Induction & Analysis

| Reagent / Material | Function & Rationale |

|---|---|

| pCTCON2 Vector | Yeast E. coli shuttle vector with GAL1 promoter, c-Myc/HA tags, and AGA2 for inducible, tagged surface display. |

| S. cerevisiae EBY100 | Genotype: GAL1-AGA1::URA3 ura3-52 trp1 leu2Δ1 his3Δ200 pep4Δ1.8 prb1Δ1.6; constitutively expresses Aga1p anchoring protein. |

| SD-CAA / SG-CAA Media | Defined synthetic media with Casamino Acids. SD (Glucose) represses display; SG (Galactose) induces expression via the GAL1 promoter. |

| Anti-c-Myc Antibody (9E10) | Primary antibody for quantitative detection of the surface-displayed fusion protein via flow cytometry. |

| Alexa Fluor 488 Secondary Antibody | Fluorescent conjugate for detecting bound primary antibody, enabling FACS quantification and sorting. |

| Fluorogenic Enzyme Substrate | e.g., fluorescein diacetate (FDA). Cell-impermeant product generated by surface enzyme activity provides a direct FACS-sortable signal. |

| Propidium Iodide (PI) | Membrane-impermeant DNA dye used to stain and gate out dead cells, ensuring sorting is based on viable, functional displayers. |

| PBSA Buffer (PBS + 0.5% BSA) | Standard wash and labeling buffer; BSA reduces non-specific antibody binding to cells. |

Application Notes

Within a high-throughput FACS screening pipeline for enzyme evolution, the selection of a fluorescent substrate and its incubation conditions are critical. These parameters dictate the dynamic range of the screen, its throughput, and the biological relevance of the identified variants. This document details the core principles and protocols for optimizing substrate incubation.

1. Kinetic Considerations for FACS Sorting Windows: Enzyme variants generated via directed evolution exhibit a broad spectrum of catalytic efficiencies (kcat/KM). The incubation time must be calibrated to maximize the fluorescence difference between active clones (hits) and the inactive background (wild-type or negative control). Prolonged incubation can lead to saturation of high-affinity clones and signal from weakly active clones, reducing resolution. A short, kinetic "snapshot" incubation often provides the best discrimination for high-turnover variants.

2. Permeabilization Strategies for Intracellular Targets: Many engineered enzymes (e.g., polymerases, proteases, kinases) function intracellularly. To screen these libraries with non-permeant substrates, cell permeabilization is required. The method must balance substrate access with cell viability for subsequent sorting and outgrowth. Harsh detergents can lyse cells, while gentle detergents or pore-forming agents allow for controlled substrate influx.

3. Live-Cell Compatibility for Functional Screens: For enzymes where cellular context is vital (e.g., signal transduction modifiers, therapeutic enzymes), maintaining cell viability throughout incubation and sorting is non-negotiable. This requires the use of cell-permeant, non-toxic substrates (e.g., esterified fluorogenic substrates, FRET probes) and iso-osmotic, biocompatible incubation buffers.

Quantitative Comparison of Substrate Incubation Modalities

Table 1: Comparison of Key Substrate Incubation Parameters for FACS Screening.

| Parameter | Kinetic (Live-Cell) | Permeabilized | Fixed-Cell |

|---|---|---|---|

| Primary Goal | Measure activity in physiological context | Maximize substrate access for intracellular targets | Archive samples; allow harsh processing |

| Typical Incubation Time | 15 min - 2 hrs | 5 - 30 min | 30 min - overnight |

| Cell Viability Post-Incubation | >90% (Critical) | 50-90% (Sorting possible) | 0% |

| Key Buffer Components | HEPES, Glucose, Serum | Mild Detergent (e.g., Digitonin, Saponin) or Pore-forming Protein | Aldehyde Fixative (e.g., Paraformaldehyde) |

| Throughput Compatibility | High | High | Medium (fixation adds step) |

| Best for Enzymes | Esterases, Phosphatases, Secreted Proteases | Intracellular Proteases, Kinases, Polymerases | Any (but activity may be altered) |

| Signal-to-Background Ratio | Moderate | High | Variable (can be high) |

Experimental Protocols

Protocol 1: Kinetic Live-Cell Incubation for Esterase Activity (FL1/FITC Channel) Objective: To identify esterase variants with enhanced activity using a cell-permeant fluorogenic substrate in a live-cell FACS screen. Materials: Library-transformed E. coli or yeast cells in log phase, PBS+ (PBS with 1 mM MgCl2, 0.1 mM CaCl2), Fluorescein Diacetate (FDA) stock solution (10 mM in DMSO), Flow Cytometry Sheath Fluid.

- Cell Preparation: Harvest 1 x 108 library cells by centrifugation (500 x g, 5 min). Wash twice with 10 mL PBS+.

- Substrate Loading: Resuspend cells to 1 x 107 cells/mL in PBS+ pre-warmed to assay temperature (e.g., 30°C).

- Kinetic Incubation: Add FDA to a final concentration of 10 µM. Mix immediately and incubate in the dark for exactly 20 minutes.

- Sorting Arrest & Analysis: Quench the reaction by placing tubes on ice. Keep samples on ice and sort within 60 minutes. Use a non-substrate-exposed aliquot of cells to set the baseline fluorescence gate. Sort the top 0.5-1% fluorescent population.

Protocol 2: Controlled Permeabilization for Intracellular Protease Screening (FL2/PE Channel) Objective: To screen a library of intracellular protease variants using a peptide-linked R110/G-based fluorogenic substrate. Materials: Mammalian cell library (e.g., HEK293T), Permeabilization Buffer (DPBS, 0.01% Digitonin, 1 mM DTT), Protease Substrate (e.g., R110-based, 5 mM stock in DMSO), Quench Buffer (DPBS with 5% FBS).

- Cell Preparation: Harvest adherent library cells using gentle trypsinization. Wash twice with DPBS.

- Permeabilization: Resuspend 5 x 107 cells in 1 mL of ice-cold Permeabilization Buffer. Incubate on ice for 10 minutes with gentle agitation.

- Substrate Incubation: Add the fluorogenic protease substrate to a final concentration of 50 µM. Immediately transfer the tube to a 37°C water bath and incubate for 15 minutes.

- Reaction Quench & Sorting: Add 10 mL of ice-cold Quench Buffer to stop permeabilization and substrate conversion. Pellet cells (300 x g, 5 min). Resuspend in Quench Buffer for sorting. Gate on viable cells (using a viability dye in a separate channel) and sort the most fluorescent 1% population.

Visualizations

Diagram 1: Substrate incubation pathways for FACS screening.

Diagram 2: Decision tree for selecting a substrate incubation method.

The Scientist's Toolkit

Table 2: Key Research Reagent Solutions for Substrate Incubation.

| Reagent/Material | Function & Rationale | Example Product/Catalog |

|---|---|---|

| Fluorescein Diacetate (FDA) | Cell-permeant prosubstrate. Esterases cleave acetate groups to release fluorescent fluorescein. Ideal for live-cell, kinetic assays. | Sigma-Aldrich, F7378 |

| Digitonin | Mild, cholesterol-dependent detergent. Creates precise pores in mammalian cell membranes for substrate access with retained viability. | Thermo Fisher, BN2006 |

| Paraformaldehyde (PFA) | Crosslinking fixative. Preserves cellular architecture and halts enzymatic activity at a defined timepoint. | Electron Microscopy Sciences, 15710 |

| R110 (Rhodamine 110)-based Substrates | Ultra-bright, doubly-quenched fluorogenic substrates for proteases. High signal-to-noise upon cleavage. | Thermo Fisher, custom synthesis |

| CCF2/4-AM (FRET Substrate) | Cell-permeant, β-lactamase FRET substrate. Enables ratiometric measurement in live cells, minimizing artifacts. | Invitrogen, K1095 |

| HEPES-buffered Saline | Physiological buffer with superior pH stability vs. bicarbonate buffers during ambient incubation. | Gibco, 15630080 |

| DMSO (Cell Culture Grade) | High-purity solvent for dissolving hydrophobic fluorogenic substrates. Minimizes cellular stress. | Sigma-Aldrich, D2650 |

| Viability Dye (e.g., PI, 7-AAD) | Membrane-impermeant DNA dye. Critical for gating out dead cells in permeabilization assays to ensure sort recovery. | BioLegend, 420403 (7-AAD) |

Within the broader thesis on leveraging Fluorescence-Activated Cell Sorting (FACS) for high-throughput enzyme evolution, the implementation of precise gating strategies is the critical step that transforms raw fluorescence data into isolated, top-performing variants. This protocol details the application of multicolor FACS to screen enzyme libraries, focusing on strategies to gate for specific activity, expression, and stability, thereby enabling the direct recovery of clones with enhanced catalytic properties for drug development and biocatalysis.

Table 1: Typical FACS Gating Parameters and Thresholds for Enzyme Variant Screening

| Parameter | Purpose | Typical Target / Threshold | Rationale |

|---|---|---|---|

| FSC-A vs. SSC-A | Cell/particle size & complexity gate | Exclude debris, select intact cells/beads | Ensures analysis is on single, healthy cells or library display particles. |

| Singlets Gate (FSC-H vs. FSC-A) | Exclude doublets/aggregates | Select population with linear height/area ratio | Critical for accurate 1:1 association of genotype and phenotype. |

| Fluorescence 1 (e.g., FITC) | Primary enzyme activity signal | Top 0.1% - 5% of population | Identifies variants with highest product formation or substrate turnover. |

| Fluorescence 2 (e.g., PE) | Expression/loading control | Positive, above autofluorescence | Normalizes activity to expression level, gates for properly folded/displayed enzymes. |

| Ratio Gate (F1/F2) | Specific Activity | Threshold set by control variants | Isolates variants with high turnover per enzyme molecule, not just high expression. |

| Sorting Purity | Recovery fidelity | 85% - 99% | Ensures sorted population is enriched for desired phenotype. |

| Sorting Rate | Throughput | 10,000 - 50,000 events/sec | Balances screening depth with cell viability and sort duration. |

Detailed Experimental Protocols

Protocol 1: FACS-Based Screening of a Surface-Displayed Enzyme Library

This protocol is for yeast or bacterial surface display systems where the enzyme variant is covalently linked to the cell surface.

Materials: Induced library culture, fluorescent substrate (e.g., fluorescein-diacetate for esterases), wash buffer (PBS + 0.5% BSA), control strains (positive/negative), FACS sorter.

Procedure:

- Induction & Harvest: Grow library to mid-log phase and induce enzyme expression under optimal conditions. Harvest cells by centrifugation (3,000 x g, 5 min).

- Substrate Incubation: Resuspend cell pellet in wash buffer containing the fluorogenic substrate. Concentrations and incubation times (typically 30 min - 2 hours on ice or at controlled temperature) must be empirically determined using control strains.

- Washing: Pellet cells and wash twice with ice-cold wash buffer to stop the reaction and remove excess substrate.

- Sample Preparation: Resuspend cells in wash buffer at a density of ~1-5 x 10^7 cells/mL. Pass through a 35-70 µm cell strainer to remove clumps.

- FACS Analysis & Gating: Run sample on a calibrated sorter. Apply the following sequential gates: a. P1: Viable Cells on FSC-A vs. SSC-A plot. b. P2: Singlets on FSC-H vs. FSC-A plot. c. P3: Expressing Cells using the fluorescence channel for the expression tag (e.g., immunostaining with a fluorescent antibody). d. P4: High-Activity Cells using the fluorescence channel for the enzymatic product. Set the gate boundary based on the top 0.1-1% of the active control strain.

- Sorting: Sort the P4 population directly into recovery media or 96-well plates containing rich media. Collect a sufficient number of cells for statistical representation (e.g., 10-50x library diversity).

- Recovery & Expansion: Incubate sorted cells to allow for outgrowth before plasmid isolation or re-induction for subsequent rounds of screening.

Protocol 2: Intracellular Enzyme Screening using a Co-Expression Reporter

This protocol uses a genetically encoded biosensor or coupled reaction where product formation is linked to fluorescence inside the cell (e.g., transcription factor-based biosensors).

Materials: Library transformed with dual-plasmid or operon system (enzyme + biosensor), growth media, FACS sorter, control plasmids.

Procedure:

- Library Cultivation: Grow the library under conditions that induce simultaneous expression of the enzyme variant and the biosensor/reporter system.

- Equilibration: Allow sufficient time for the enzymatic reaction to produce enough metabolite to activate the biosensor and subsequent fluorescence signal (often requires overnight growth).

- Sample Preparation: Harvest cells, wash, and resuspend in appropriate buffer or media. Keep samples on ice and protected from light.

- FACS Analysis & Gating: Run on sorter. Apply sequential gates: a. P1: Viable Cells on FSC-A vs. SSC-A. b. P2: Singlets on FSC-H vs. FSC-A. c. P3: Library Expression Gate using a control fluorescent protein (e.g., constitutive GFP) to select only cells containing the library construct. d. P4: Biosensor Activation Gate using the reporter fluorescence channel (e.g., RFP). Set gate using negative control (no substrate) and positive control (high-activity variant).

- Sorting & Recovery: Sort the brightest population from the P4 gate. Perform bulk sorting into media for plasmid prep or single-cell sorting into 384-well plates for clone isolation.

Visualizations

Title: Sequential Gating Strategy for FACS-Based Enzyme Screening

Title: Logic for Specific Activity Gating

The Scientist's Toolkit: Essential Research Reagent Solutions

Table 2: Key Reagents and Materials for FACS Enzyme Screening

| Item | Function & Application in Protocol | Example/Notes |

|---|---|---|

| Fluorogenic Substrate | Enzyme-specific probe that becomes fluorescent upon turnover. Core of activity detection. | Fluorescein diacetate (esterases/lipases), Resorufin derivatives (phosphatases), Coumarin-based substrates. |

| Cell Viability Dye | Distinguishes live from dead cells; critical for accurate gating on healthy, functional cells. | Propidium Iodide (PI), DAPI (for fixed cells), LIVE/DEAD Fixable Near-IR stain. |

| Expression Tag Antibody | Fluorescently conjugated antibody for detection of surface expression levels. Normalization control. | Anti-c-Myc-FITC, Anti-HA-PE, Anti-FLAG-APC. |

| FACS Sheath Fluid & Calibration Beads | Sterile, particle-free fluid for stream stability. Beads for instrument alignment and sensitivity setup. | BD FACSFlow sheath fluid. Rainbow or SPHERO calibration particles. |

| Sort Collection Media | High-protein, antibiotic-containing media to maintain viability of sorted cells. | Rich media (LB, YPD) with 20-50% serum or 1% BSA, and 2x antibiotic. |

| Cell Strainer (35-70 µm) | Removes cell clumps and aggregates to prevent nozzle clogging and ensure single-cell sorting. | Pluristrainer or Flowmi cell strainers. |

| Single-Cell Dispensing Plates | For recovery of individual clones post-sort for subsequent characterization. | 96-well or 384-well tissue culture plates pre-filled with growth media. |

Within the workflow of high-throughput enzyme evolution using Fluorescence-Activated Cell Sorting (FACS), the steps following the primary sort are critical for success. This application note details the protocols for recovering viable cell populations from sorted samples, expanding them for analysis, and ultimately deriving clonal cultures to isolate and validate individual enzyme variants. These steps bridge the gap between identifying a hit in a screen and generating robust, reproducible data for downstream characterization and drug development pipelines.

Key Principles and Quantitative Benchmarks

Post-sort recovery is influenced by multiple factors. The table below summarizes key quantitative benchmarks for successful workflow execution.

Table 1: Post-FACS Recovery & Expansion Benchmarks

| Parameter | Typical Target Range | Impact on Success |

|---|---|---|

| Sorting Pressure | 20-30 psi (for most flow cytometers) | Higher pressure increases shear stress, reducing immediate post-sort viability. |

| Collection Medium | Rich recovery medium + 20-50% conditioned medium | Conditioned medium supplies growth factors and signals, boosting recovery rates. |

| Initial Post-Sort Viability | >70% (aim for >85%) | Low viability compromises expansion and increases risk of culture loss. |

| Initial Inoculum Density (Microtiter) | 5 x 10^4 – 1 x 10^5 cells/well (96-well) | Optimal for paracrine signaling without immediate over-crowding. |

| Doubling Time (Post-Recovery) | <24 hours (for most microbial/yeast systems) | Indicates healthy, adapted culture ready for clonal isolation. |

| Time to First Analysis (Expansion) | 48-72 hours post-sort | Allows for sufficient biomass for enzymatic re-assay or DNA extraction. |

| Single-Cell Cloning Efficiency | 0.5% - 5% (varies widely by host) | Critical bottleneck; defines the number of sorted cells required for clonal output. |

Detailed Protocols

Protocol 1: Immediate Post-Sort Recovery and Bulk Expansion

Objective: To maximize viability and initiate culture growth from sorted cell populations collected in liquid medium.

Pre-Sort Preparation:

- Prepare Recovery Medium: Pre-warm standard growth medium supplemented with 1.5x the usual nutrient concentration. Add antioxidants (e.g., 0.1% sodium pyruvate) if applicable.

- Prepare Conditioned Medium: Harvest supernatant from a mid-log phase culture of the host strain (not expressing the library), filter sterilize (0.22 µm).

- Final Collection Medium: Combine 50% Recovery Medium and 50% Conditioned Medium. Aliquot 150-200 µL per well in a 96-well deep-well plate (1.2 mL capacity). Keep plates at 37°C (or host-specific temperature) until sort.

Sort Collection:

- Use the sorter's "Yield" or "Purity" mode based on need. For rare populations, "Yield" is preferred.

- Set collection plate on a chilled block or in the sorter's cooled collection chamber (4-10°C) to minimize metabolic stress during extended sorts.

- Limit sort duration per aliquot to prevent medium evaporation and temperature increase.

Post-Sort Incubation and Expansion:

- Immediately after sorting, centrifuge the collection plate at low speed (e.g., 300 x g, 5 min) to pellet cells.

- Carefully aspirate ~100 µL of supernatant, leaving cells in ~100 µL.

- Gently resuspend the pellet and transfer the entire volume to a new 96-deep well containing 900 µL of fresh, pre-warmed Recovery Medium.

- Cover with a breathable seal and incubate with shaking (≥800 rpm for microbial systems) at appropriate temperature for 24-48 hours.

- Monitor growth by OD600. Once OD600 > 0.5, cultures are ready for secondary screening or clonal isolation.

Protocol 2: Single-Cell Dispensing for Clonal Culture Generation

Objective: To isolate individual cells from a sorted, expanded population to establish genetically homogenous clonal cultures.

Cell Preparation:

- Harvest cells from the expanded bulk culture (Protocol 1) during mid-exponential phase.

- Wash cells twice in sterile PBS or sorting buffer to remove secreted metabolites.

- Resuspend in sterile, particle-free sorting buffer at a density of 1-5 x 10^6 cells/mL. Filter through a 35 µm cell strainer cap to remove aggregates.

Single-Cell Sorting Setup:

- On the FACS sorter, configure for single-cell deposition using the "Single-Cell" or "Cell-Deposition" unit.

- Set stringent gating on FSC-H vs FSC-W and SSC-H vs SSC-W to select singlets.

- Use a low nozzle size (e.g., 70 µm) and low pressure to enhance viability.

- Prepare destination plates: 96- or 384-well microtiter plates pre-filled with 50-100 µL of Conditioned Recovery Medium per well.

Sorting and Clonal Outgrowth:

- Dispense one confirmed single cell per well. Utilize the instrument's "Single-Cell Sort Mask" feature.

- After sorting, seal plates, centrifuge briefly (100 x g, 2 min) to settle cells and medium.

- Incubate statically for 24-48 hours to allow initial division, then initiate gentle shaking.

- Monitor growth for 3-7 days. Score wells for clonal growth (typically 10-30% of wells).

Validation of Clonality:

- Method A (Imaging): Use automated microscopy post-sort to confirm a single cell/well.

- Method B (Replica Screening): Plate a fraction of the grown culture on solid medium. A uniform colony morphology suggests clonality.

- Method C (PCR/Sequencing): For critical clones, sequence the gene of interest from the culture to confirm a single genotype.

Visualizing the Workflow and Key Pathways

The following diagrams, generated using Graphviz DOT language, illustrate the experimental workflow and a key cellular signaling pathway activated during recovery.

Post-FACS Recovery to Clonal Culture Workflow

Cellular Stress & Recovery Pathways Post-FACS

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Post-FACS Recovery and Cloning

| Item | Example Product/Catalog | Function in Protocol |

|---|---|---|

| Cell Recovery Medium | SOC Outgrowth Medium (Microbial), RPMI-1640 + 10% FBS (Mammalian) | Rich, non-selective medium to resuscitate metabolically stressed cells post-sort. |

| Conditioned Medium | Custom-prepared from host strain. | Supplies quorum-sensing molecules, growth factors, and spent metabolites that improve single-cell recovery. |

| Antioxidant Supplement | Sodium Pyruvate, N-Acetyl Cysteine | Scavenges reactive oxygen species (ROS) generated during sorting, improving viability. |

| Low-Binding Microplates | Non-treated U-bottom 96-well plates | Prevents cell adhesion to well walls, maximizing recovery during low-density culture steps. |

| Breathable Sealing Film | AeraSeal or gas-permeable seals | Allows for adequate gas exchange (O2 in, CO2 out) during extended shaken incubation without evaporation. |

| Single-Cell Sorting Sheath Fluid | BD FACSFlow, Thermo Fisher Sorter Sheath Fluid (0.22 µm filtered) | Particle-free, isotonic buffer ensuring stable stream and minimizing nozzle clogs during single-cell sorts. |

| Clonality Verification Kit | Whole Genome Amplification Kit for single cells | Amplifies genomic DNA from a putative clonal culture for subsequent sequencing confirmation. |

Optimizing FACS Screens: Solving Common Pitfalls and Enhancing Signal-to-Noise

In high-throughput directed evolution of enzymes via Fluorescence-Activated Cell Sorting (FACS), signal-to-noise ratio is paramount. Background fluorescence, arising from host cell autofluorescence or impure substrates, directly obscures the detection of weak, beneficial enzymatic activities, limiting the evolutionary search space. This application note details practical strategies, framed within a thesis on advancing FACS methodologies, to minimize these noise sources through systematic host engineering and rigorous substrate purification protocols, thereby enhancing screening sensitivity and library throughput.

Host Engineering to Reduce Cellular Autofluorescence

Cellular autofluorescence primarily stems from endogenous flavins, NAD(P)H, and respiratory chain components. Engineering the host strain to minimize these fluorophores is a critical first step.

Key Experimental Protocol: Construction of an E. coli Low-Fluorescence Strain

Objective: Generate a host with reduced autofluorescence in the GFP (FITC) and mCherry (PE-Texas Red) channels.

Materials:

- Parental strain: E. coli BW25113 (ΔaraBAD, ΔlacZ).

- Keio collection knockout strains (or appropriate CRISPR/Cas9 plasmids).

- P1 vir phage lysate for transduction.

- LB and M9 minimal media.

- FACS analyzer.

Procedure:

- Target Gene Selection: Select knockouts of genes involved in synthesis/uptake of fluorescent metabolites. Primary targets include:

- flu: Encodes outer membrane protein for flavin uptake.

- ribD, ribE: Involved in riboflavin (precursor to FMN/FAD) biosynthesis.

- entD: Required for enterobactin synthesis (siderophore with fluorescence).

- P1 Phage Transduction: Use P1 phage grown on donor Keio knockout strains (Δflu, ΔribD, etc.) to transduce the knockout alleles into the clean parental BW25113 background.

- Strain Validation: Isolate transductants, confirm genotype by PCR, and measure autofluorescence via FACS using standard FITC (488/530 nm) and PE-Texas Red (561/610 nm) filter sets. Compare median fluorescence intensity (MFI) to parental strain.

- Iterative Engineering: Combine multiple knockouts via sequential transduction to achieve additive reduction.

Results Summary (Quantitative Data): Table 1: Autofluorescence Reduction in Engineered E. coli Strains (Median Fluorescence Intensity, a.u.)