Green Chemistry and Biocatalysis: Principles, Applications, and Sustainable Drug Development

This article provides a comprehensive analysis of how the 12 principles of green chemistry are driving the adoption of biocatalysis in pharmaceutical and chemical manufacturing.

Green Chemistry and Biocatalysis: Principles, Applications, and Sustainable Drug Development

Abstract

This article provides a comprehensive analysis of how the 12 principles of green chemistry are driving the adoption of biocatalysis in pharmaceutical and chemical manufacturing. Tailored for researchers, scientists, and drug development professionals, it explores the foundational framework of green chemistry, details cutting-edge methodologies like directed evolution and AI-driven enzyme design, and presents real-world case studies from cardiovascular drug synthesis to API manufacturing. The content addresses critical implementation challenges and optimization strategies, while validating the approach through comparative economic and environmental metrics. By synthesizing the latest research and industry trends, this resource equips scientific professionals with the knowledge to design more sustainable, efficient, and economically viable synthetic processes.

The Foundation of Green Chemistry: From Theoretical Principles to Industrial Transformation

The field of green chemistry emerged as a transformative response to the environmental challenges posed by traditional chemical manufacturing. The 1998 publication of "Green Chemistry: Theory and Practice" by Paul Anastas and John Warner introduced a comprehensive framework that would systematically reshape the chemical industry's approach to process design and environmental stewardship [1]. This foundational work established the Twelve Principles of Green Chemistry, providing chemists and engineers with a pragmatic design protocol for reducing the environmental impact of chemical products and processes [2]. The framework emerged shortly after the U.S. Pollution Prevention Act of 1990, which signaled a strategic shift from pollution control (end-of-pipe treatment) to pollution prevention through improved design [2]. Rather than managing waste after its creation, the green chemistry approach sought to design waste out of systems entirely.

The timing of this framework coincided with growing awareness of the chemical industry's environmental footprint and the economic inefficiencies of traditional manufacturing approaches. In sectors such as pharmaceutical manufacturing, traditional synthesis methods often generated 50-100 times more waste than product, creating enormous disposal costs and environmental liabilities [1]. The Anastas and Warner framework fundamentally challenged this paradigm by positing that environmental protection and economic performance could be aligned through intelligent molecular design. Today, this framework has evolved from an academic concept to an industry-standard methodology driving billions in capital investment across multiple manufacturing sectors [1].

The Foundational Principles: A Systematic Framework

The Twelve Principles of Green Chemistry established by Anastas and Warner provide a holistic design framework encompassing hazard reduction, resource efficiency, and accident prevention. These principles address specific aspects of chemical design, synthesis, and lifecycle management while creating synergistic benefits when implemented as a cohesive system [1] [2].

Table 1: The Twelve Principles of Green Chemistry and Their Industrial Impact

| Principle | Core Concept | Industrial Impact |

|---|---|---|

| 1. Prevention | Prevent waste rather than treat it | Eliminates waste at source, reduces disposal costs |

| 2. Atom Economy | Maximize material incorporation into final product | Reduces raw material consumption and feedstock costs |

| 3. Less Hazardous Synthesis | Use and generate substances with minimal toxicity | Protects workers, communities, and ecosystems |

| 4. Safer Chemical Design | Design products to be effective yet non-toxic | Reduces product lifecycle risks and regulatory burden |

| 5. Safer Solvents & Auxiliaries | Minimize use of auxiliary substances | Decreases VOC emissions and solvent-related hazards |

| 6. Energy Efficiency | Conduct reactions at ambient temperature/pressure | Lowers energy consumption and carbon footprint |

| 7. Renewable Feedstocks | Use agricultural instead of fossil sources | Reduces fossil fuel dependence and enhances sustainability |

| 8. Reduce Derivatives | Avoid protecting groups and temporary modifications | Minimizes synthesis steps, waste, and material use |

| 9. Catalysis | Use catalytic rather than stoichiometric reagents | Reduces reagent quantities and improves selectivity |

| 10. Degradation Design | Products should break down to harmless substances | Prevents environmental accumulation and persistence |

| 11. Real-time Analysis | Monitor processes to prevent pollution | Enables immediate corrections and process control |

| 12. Safer Chemistry for Accident Prevention | Choose substances that minimize accident potential | Protects facilities and communities from chemical accidents |

The principles collectively address the three dimensions of sustainability: environmental protection, economic performance, and social responsibility. Principles 1 (Prevention) and 2 (Atom Economy) establish waste prevention as fundamentally superior to treatment or cleanup, with atom economy extending this concept by maximizing starting material incorporation into final products [1]. Principles 3, 4, 5, and 12 focus on hazard reduction throughout chemical lifecycles, advocating for less hazardous synthesis, safer chemical design, safer solvents, and inherently safer processes to minimize accident potential [1] [2]. Principles 6 through 9 emphasize resource conservation and process efficiency, including energy efficiency, renewable feedstocks, derivative reduction, and catalytic processes [1].

The framework's enduring strength lies in its systems-thinking approach. Rather than optimizing single parameters in isolation, the principles function as a cohesive system with mutually reinforcing components [2]. This integrated perspective has proven essential for addressing the interconnected challenges of energy, water, and materials management in chemical manufacturing.

Historical Evolution and Industrial Adoption

The two decades following the framework's publication witnessed its gradual integration into industrial practice, accelerated by both regulatory pressures and economic imperatives. The 1990s saw the establishment of foundational programs including the EPA's research grant program encouraging chemical product redesign and the introduction of the annual Presidential Green Chemistry Challenge Awards in 1996 [2]. The late 1990s marked key institutional developments with the publication of the Twelve Principles in 1998, the launch of the Royal Society of Chemistry's journal Green Chemistry in 1999, and the proliferation of international green chemistry networks [2].

A significant turning point came during the 2008 global financial crisis, which paradoxically accelerated green chemistry adoption as companies scrutinized manufacturing costs seeking efficiency gains [1]. The economic downturn revealed opportunities to reduce raw material consumption and waste disposal expenses through green chemistry principles. By approximately 2015, major chemical manufacturers like BASF, Dow, and DuPont had incorporated green chemistry into standard R&D protocols [1].

The framework's influence received authoritative recognition when the 2005 Nobel Prize for Chemistry citation commended the work of Chauvin, Grubbs, and Schrock as "a great step forward for green chemistry" [2]. This endorsement from the highest levels of science signaled green chemistry's arrival as a legitimate and influential discipline.

Diagram 1: Evolution of Green Chemistry Timeline

Biocatalysis as a Implementation Vehicle

Biocatalysis has emerged as a powerful implementation vehicle for green chemistry principles, enabling the practical application of Anastas and Warner's framework across multiple industries. Biocatalysis can now be considered a key enabling technology for implementing sustainable chemicals manufacture, aligning with at least ten of the twelve green chemistry principles [3]. The technology leverages natural or engineered enzymes to facilitate chemical transformations under mild conditions, minimizing energy requirements and hazardous byproduct formation.

The pharmaceutical industry has led biocatalysis adoption driven by both sustainability pressures and economic incentives [1]. Companies report 30-50% cost reductions alongside environmental improvements through enzyme-catalyzed steps in production routes for major drugs including statins and diabetes medications [1]. Biocatalysis exemplifies multiple green chemistry principles simultaneously, making it a cornerstone of sustainable manufacturing transformation [1].

Key advantages of biocatalysis in green chemistry include:

- Reactions at ambient conditions eliminating energy-intensive heating and cooling

- Aqueous reaction environments that replace toxic organic solvents

- Extraordinary selectivity minimizing byproduct formation and purification requirements

- Biodegradable catalysts (enzymes) produced from renewable fermentation sources

- Reduced waste streams that lower disposal costs and environmental impact [1]

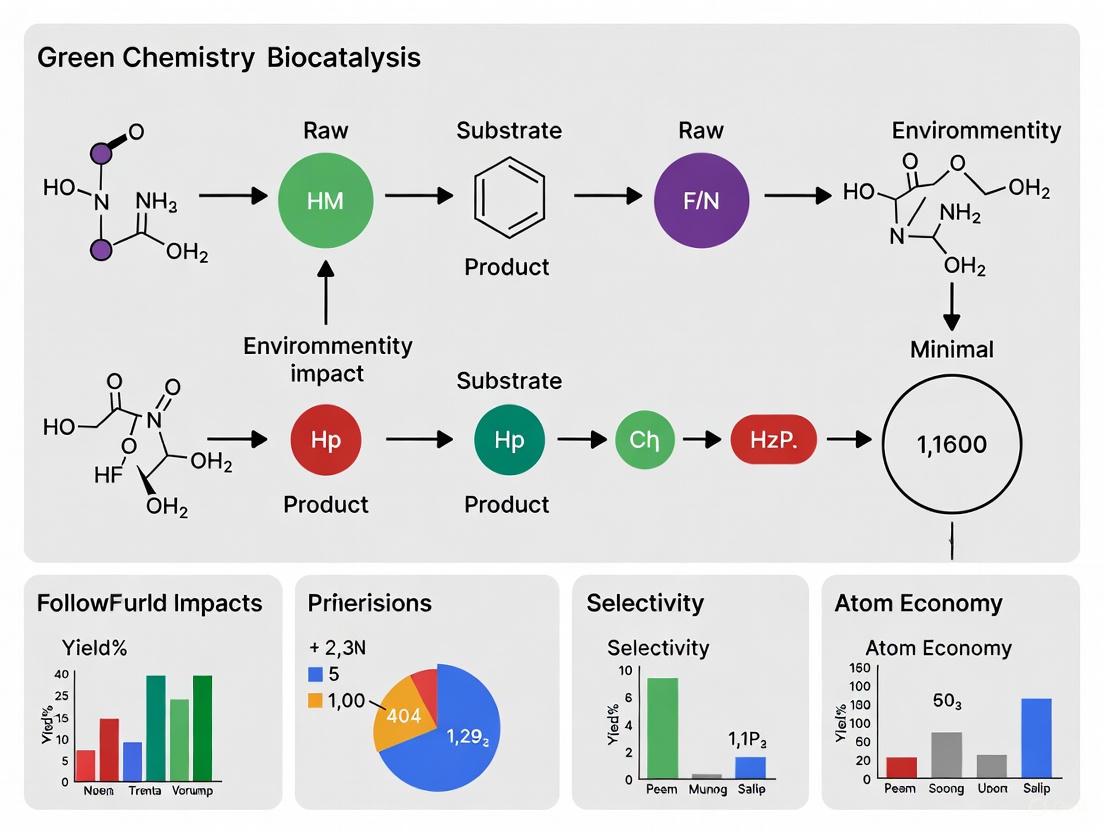

Diagram 2: Biocatalysis Implementation of Green Principles

Quantitative Metrics and Performance Assessment

The adoption of green chemistry principles has driven the development of standardized metrics to quantify environmental and economic benefits. These metrics enable objective comparison of alternatives and tracking of improvements over time [1].

Table 2: Green Chemistry Performance Metrics and Industry Benchmarks

| Metric | What It Measures | Traditional Processes | Green Chemistry Targets |

|---|---|---|---|

| E-factor | Mass waste per mass product | >100 for pharmaceuticals, 5-50 for fine chemicals | <5 for specialties, 10-20 for pharmaceuticals |

| Atom Economy | Efficiency of molecular incorporation into product | Varies widely, often <50% | >70% considered good |

| Process Mass Intensity (PMI) | Total mass input per product mass | Often >100 for complex molecules | <20 for pharmaceuticals |

| Solvent Intensity | Solvent mass per product mass | Often 50-100 for pharmaceuticals | <10 target |

| Energy Reduction | Process energy consumption | High-temperature/pressure operations | 80-90% reduction via ambient biocatalysis |

The E-factor (environmental factor) has been particularly influential in highlighting waste generation issues, dividing total waste mass by product mass [1]. Traditional pharmaceutical manufacturing often showed E-factors exceeding 100, meaning that producing one kilogram of product generated over 100 kilograms of waste [1]. Green chemistry improvements have systematically reduced this ratio to 10-20 or better in many pharmaceutical applications [1]. Process Mass Intensity (PMI) provides a more comprehensive view by including all inputs including solvents and water, revealing hidden resource consumption that might be overlooked in simpler metrics [1].

Case Study: Pharmaceutical Manufacturing Applications

The pharmaceutical industry provides compelling case studies of green chemistry principles applied through biocatalysis, demonstrating both environmental and economic benefits. Merck's implementation of biocatalysis for Sitagliptin (Januvia) manufacturing exemplifies this approach at commercial scale [1]. The company developed a transaminase enzyme producing the chiral amine building block, replacing a rhodium-catalyzed hydrogenation requiring high pressure [1]. The biocatalytic route achieved a 19% reduction in waste and eliminated a genotoxic intermediate while maintaining economic viability [1].

Penicillin G acylase (PGA) applications demonstrate the evolution of biocatalytic processes over time [4]. Initially used for the hydrolysis of Penicillin G to produce 6-Aminopenicillanic acid, this enzyme is now the second most widely used in the world for commercial synthesis [4]. Recent advances have focused on reversing the hydrolysis reaction by using alternative acyl donors to produce semi-synthetic penicillins, though challenges remain in balancing hydrolytic and synthetic activities of the enzyme [4]. Strategies to improve PGA performance include bioprospecting for improved variants, solvent engineering, in situ product removal, and one-pot reaction cascades [4].

Table 3: Research Reagent Solutions for Biocatalysis Implementation

| Reagent/Catalyst Type | Function | Green Chemistry Advantages |

|---|---|---|

| Engineered Transaminases | Chiral amine synthesis | Replaces heavy metal catalysts, high-pressure reactions |

| Immobilized Enzymes | Heterogeneous biocatalysts | Enables catalyst reuse, continuous processing |

| Deep Eutectic Solvents | Green reaction media | Biodegradable, low toxicity alternatives to organic solvents |

| Whole-Cell Biocatalysts | Self-regenerating enzyme systems | Eliminates enzyme purification, cofactor regeneration |

| Enzyme Cascade Systems | Multi-step synthesis in one pot | Minimizes intermediate purification, reduces solvent use |

The experimental protocol for implementing biocatalysis typically begins with enzyme discovery through metagenomics or genome mining, followed by enzyme engineering via directed evolution or rational design to enhance stability, activity, and selectivity [3] [4]. Process optimization includes reaction engineering to identify optimal conditions (pH, temperature, solvent system) and downstream processing development for efficient product isolation [5]. The integration of analytical techniques such as chromatography and spectroscopy enables precise monitoring of reaction kinetics, substrate conversion, and enzyme stability throughout process development [5].

Future Trajectory and Research Directions

The future evolution of green chemistry and biocatalysis will be shaped by several converging technological and regulatory trends. Artificial intelligence is accelerating green chemistry process discovery, while synthetic biology enables new bio-based production pathways [1]. These advances are complemented by increasingly stringent regulatory mandates requiring lifecycle environmental assessments and the implementation of carbon pricing mechanisms that make fossil feedstocks economically disadvantageous [1].

The valorization of waste biomass represents a particularly promising direction for implementing green chemistry principles at scale [3]. Traditional waste streams including crop residues, food processing waste, and forestry byproducts contain useful chemical structures that can be transformed into valuable products [1]. For example, citrus processing generates millions of tons of peel waste annually containing valuable limonene solvent, while lignin from wood pulping represents enormous untapped chemical potential that has traditionally been burned for energy rather than exploited for chemical value [1].

The educational dimension of green chemistry continues to evolve, with growing recognition that professionals must possess a diverse set of specialized skills spanning molecular biology, biochemistry, organic chemistry, analytical chemistry, chemical engineering, and computational modeling [5]. As the field advances, interdisciplinary training becomes increasingly critical for developing next-generation biocatalysts and scalable biomanufacturing processes [5].

The 1998 Anastas and Warner framework has fundamentally transformed chemical manufacturing by providing a systematic approach to designing products and processes that reduce or eliminate hazardous substances. The principles have evolved from theoretical concepts to practical tools driving innovation across multiple industries, with biocatalysis emerging as a powerful implementation vehicle that aligns with at least ten of the twelve principles. The pharmaceutical and specialty chemical sectors have demonstrated that green chemistry can deliver both environmental benefits and economic advantages through reduced material consumption, lower energy requirements, and decreased waste disposal costs.

As the field progresses, the integration of advanced technologies including artificial intelligence, synthetic biology, and enzyme engineering will further accelerate the adoption of green chemistry principles. The transition from fossil-based feedstocks to renewable resources, coupled with the valorization of waste streams, promises to reshape the chemical industry toward a circular, bio-based economy. The continued evolution of the Anastas and Warner framework will be essential for addressing the interconnected sustainability challenges of energy, water, and materials management, ultimately enabling the design of chemical products and processes that are inherently benign for both human health and the environment.

The foundation of modern chemical manufacturing, particularly within the pharmaceutical industry, has long relied on traditional synthetic methodologies. These processes are increasingly scrutinized for their significant environmental footprint, characterized by high process mass intensity (PMI) and E-factors (kg waste/kg product). The drive towards sustainable manufacturing demands a paradigm shift from these resource-intensive linear processes to circular, efficient alternatives. This whitepaper examines the inherent environmental limitations of traditional chemistry through the lens of green chemistry principles, framing biocatalysis as a disruptive solution that offers a pathway to reduced waste, improved atom economy, and a lower carbon footprint for drug development professionals and researchers.

Traditional methods often prioritize yield and speed over environmental costs, leading to heavy reliance on hazardous solvents, precious metal catalysts, and energy-intensive purification steps [6] [7]. On scale-up, issues with heat transfer, stirring efficiency, and sensitivity to trace water or oxygen can lead to process failures, generating substantial waste [7]. Furthermore, the "race" for novel, patentable compounds in medicinal chemistry often employs capricious synthetic methodologies not designed for sustainability or scalability from the outset [7]. The following sections will quantify this environmental impact and detail how biocatalysis, aligned with green chemistry principles, presents a viable and commercially critical alternative.

Quantitative Analysis of Environmental Impact: The Case for Change

The environmental performance of chemical processes can be quantitatively assessed using key metrics, most notably the E-factor, which calculates the total mass of waste generated per unit mass of product. Traditional chemical processes, especially in pharmaceuticals, are notorious for their high E-factors.

Table 1: Typical E-Factors Across the Chemical Industry

| Industry Sector | E-Factor (kg waste/kg product) | Primary Waste Sources |

|---|---|---|

| Pharmaceuticals | 25 - 100+ | Solvents, excess reagents, purification resins, by-products [7] |

| Fine Chemicals | 5 - 50 | Solvents, reagents, aqueous streams [8] |

| Commodity Chemicals | < 1 - 5 | Process-specific by-products, packaging |

| Bulk Chemicals | < 1 | Minimal solvent use, integrated processes |

Organic solvents are a dominant contributor to hazardous waste and air pollution in traditional synthesis [6]. The environmental impact of a solvent extends beyond the reaction vessel, encompassing its entire lifecycle from raw material extraction and synthesis to transportation and ultimate disposal, a concept critically described as "The Solvent Trip" [9]. This impact can be quantified as kg CO₂ produced per kg of product, providing a more comprehensive ecological footprint than qualitative "green" claims [9].

Table 2: Comparative Environmental Impact of Common Reaction Media

| Reaction Medium | Key Advantages | Key Environmental & Process Drawbacks |

|---|---|---|

| Traditional Organic Solvents | High substrate solubility, established protocols | Volatile, often flammable/toxic, high VOC emissions, difficult waste treatment [6] [9] |

| Water | Non-toxic, non-flammable, cheap, safe | Limited solubility for organic substrates, contaminated aqueous waste streams [6] [8] |

| Solvent-Free Mechanochemistry | Eliminates solvent waste, enhances safety, can enable novel transformations [6] | Technology scale-up challenges, not suitable for all reaction types |

| Deep Eutectic Solvents (DES) | Biodegradable, low toxicity, customizable for extraction [6] | Can be viscous, complex recycling, environmental impact of components |

Biocatalysis as a Disruptive Solution

Biocatalysis leverages natural or engineered enzymes to perform chemical transformations with high efficiency and selectivity. It aligns with multiple principles of green chemistry, primarily by reducing waste at source through superior atom economy and catalyst efficiency.

A key advantage is the ability of enzymes to function in alternative reaction media. While water is the natural solvent, enabling "in-water" and "on-water" reactions that proceed even with water-insoluble reactants [6], biocatalysis can also be performed in non-aqueous media. Systematic studies have identified bio-derived solvents like limonene that can outperform traditional solvents like hexane for certain enzymatic reactions, such as the synthesis of hexyl laurate, while offering a more sustainable profile [8]. This flexibility allows process developers to balance solvent choice with reaction performance and environmental impact.

Furthermore, enzymes like imine reductases (IREDs) catalyze the direct asymmetric synthesis of chiral amines in water, providing a route to these critical pharmaceutical intermediates with high enantioselectivity and without the need for protecting groups or harsh reductants [8]. This contrasts with traditional methods that often rely on stoichiometric reagents and generate significant metal or borohydride waste.

Experimental Protocols & Methodologies in Green Biocatalysis

Protocol 1: Imine Reductase-Catalyzed Reductive Amination in Water

This protocol details a biocatalytic method for synthesizing chiral primary and secondary amines, demonstrating a green alternative to traditional reductive amination [8].

- Objective: To synthesize chiral amines via intermolecular reductive amination of carbonyl compounds using imine reductases in aqueous media.

- Principle: Imine reductases (IREDs) catalyze the direct reduction of imine intermediates formed in situ from carbonyls and amines, utilizing NAD(P)H as a cofactor to furnish chiral amine products with high chemoselectivity and stereoselectivity.

Methodology:

- Reaction Setup: In a suitable vessel, combine the carbonyl compound (e.g., aldehyde or ketone, 1.0 equiv) and the amine nucleophile (1.2 equiv) in an aqueous buffer (e.g., 100 mM phosphate buffer, pH 7.0).

- Enzyme and Cofactor Addition: Add the purified (S)- or (R)-selective imine reductase (0.5 - 2 mg/mL) and a catalytic amount of NADPH or NADH (0.1 - 1.0 mol%). The specific IRED enantiomer is selected based on the desired product stereochemistry.

- Cofactor Recycling (if applicable): To drive the reaction to completion, include a cofactor recycling system, such as glucose dehydrogenase (GDH) and glucose, to regenerate NADPH from NADP+.

- Incubation: Stir the reaction mixture gently at 25-30°C for 6-24 hours, monitoring conversion by analytical techniques (e.g., HPLC, GC).

- Work-up and Purification: After completion, extract the product using a green solvent (e.g., ethyl acetate or cyclopentyl methyl ether). Purify the crude product via chromatography or distillation to obtain the pure chiral amine.

Protocol 2: Biocatalytic Esterification in Bio-Derived Solvents

This protocol outlines a kinetic study for evaluating bio-derived solvents as sustainable media for enzymatic synthesis, addressing the solvent waste problem [8].

- Objective: To assess the performance of supported lipase B from Candida antarctica (Novozyme 435) in bio-derived solvents for the synthesis of hexyl laurate.

- Principle: Enzyme activity in organic solvents correlates with solvent properties. Hydrogen-bond accepting ability and molar volume are key parameters influencing enzyme activity by affecting the enzyme's hydration shell.

Methodology:

- Solvent Screening: Prepare a panel of classical and bio-derived solvents (e.g., n-hexane, limonene, p-cymene) in sealed reaction vials.

- Reaction Initiation: To each vial, add 1-hexanol (50 mM), dodecanoic acid (50 mM), and the bio-derived solvent (2 mL). Initiate the reaction by adding Novozyme 435 (10 mg/mL).

- Kinetic Monitoring: Incubate the vials at 40°C with shaking. Withdraw aliquots at regular intervals and analyze by GC or TLC to determine initial reaction rates.

- Data Analysis: Correlate the observed initial reaction rates with the physicochemical properties of the solvents (e.g., log P, hydrogen-bond acceptance, molar volume) to identify optimal green solvent systems.

Diagram 1: A workflow for developing sustainable biocatalytic processes, integrating solvent selection, process intensification, and life-cycle assessment (LCA) to minimize environmental impact [9].

The Scientist's Toolkit: Essential Reagents & Materials

Successful implementation of green biocatalysis requires specific reagents and materials. The following table details key components for the protocols described.

Table 3: Key Research Reagent Solutions for Green Biocatalysis

| Reagent/Material | Function in Biocatalytic Process | Green Chemistry Advantage |

|---|---|---|

| Imine Reductases (IREDs) | Catalyzes enantioselective reductive amination of carbonyls to chiral amines [8]. | Enables synthesis in aqueous media; high atom economy; avoids use of chiral auxiliaries or metal catalysts. |

| Novozyme 435 | Immobilized lipase B from Candida antarctica; used for esterifications, transesterifications, and amide formations [8]. | Heterogeneous catalyst for easy recovery and reuse; operates in green solvents like limonene. |

| Deep Eutectic Solvents (DES) | Customizable solvent for extraction of metals from e-waste or bioactives from biomass [6]. | Biodegradable, low-toxicity alternative to harsh mineral acids or VOCs; supports circular economy. |

| Bio-derived Solvents (Limonene) | Renewable reaction medium for non-aqueous biocatalysis [8]. | Replaces petrochemical-derived solvents (e.g., hexane); reduces carbon footprint and toxicity. |

| Cofactor Recycling Systems (e.g., GDH/Glucose) | Regenerates expensive NAD(P)H cofactors stoichiometrically consumed by oxidoreductases [10]. | Shifts process from stoichiometric to catalytic, dramatically reducing waste and cost. |

| Unspecific Peroxygenases (UPOs) | Catalyzes selective oxyfunctionalizations (e.g., C-H activation) without directed evolution [10]. | High total turnover numbers vs. traditional P450s; uses H₂O₂ as a clean oxidant. |

The future of green biocatalysis is being shaped by several key technological trends. Artificial Intelligence is accelerating enzyme discovery and engineering, with models now capable of predicting beneficial mutations and designing enzymes with novel functions, reducing reliance on wet-lab trial-and-error [6] [10]. Furthermore, the industry is moving towards complex multi-enzyme cascades for one-pot synthesis, minimizing isolation steps and waste generation [10]. The integration of mechanochemistry for solvent-free synthesis and the application of life-cycle analysis (LCA) as a primary decision-making tool further underscore the commitment to holistic sustainability [6] [10].

In conclusion, the disruption of traditional chemical processes is an imperative driven by untenably high E-factors and significant environmental impacts. Biocatalysis, underpinned by the principles of green chemistry, offers a scientifically robust and commercially viable path forward. Through the adoption of enzymes operating in water or bio-derived solvents, solvent-free methodologies, and AI-driven engineering, researchers and drug development professionals can design synthetic routes that are not only efficient and selective but also inherently safer and more sustainable. The transition is no longer merely a scientific ambition but a commercial and ethical necessity for the future of the chemical and pharmaceutical industries.

Green chemistry, defined as the design of chemical products and processes that reduce or eliminate the use or generation of hazardous substances, provides a critical framework for developing sustainable industrial processes [11]. Within this framework, biocatalysis—the use of natural catalysts, primarily enzymes, to perform chemical transformations—has emerged as a powerful technology that aligns intrinsically with green chemistry goals [3]. The pharmaceutical industry, in particular, has driven adoption of these principles due to increasing regulatory pressure and the environmental imperative to reduce waste generation, which historically exceeded 100 kilograms per kilogram of active pharmaceutical ingredient (API) in traditional syntheses [12].

This technical review examines how biocatalysis embodies three core green chemistry principles: waste prevention, atom economy, and safer design. We analyze quantitative metrics demonstrating environmental and economic advantages, present detailed experimental methodologies, and provide visualization tools to guide researchers in implementing these principles. The integration of these principles is not merely complementary but foundational to advancing biocatalysis as a sustainable manufacturing technology across chemical sectors.

Principle 1: Waste Prevention

Theoretical Foundation

The first principle of green chemistry states that "it is better to prevent waste than to treat or clean up waste after it has been created" [12] [13]. This preemptive approach represents a fundamental shift from traditional pollution control strategies that focus on end-of-pipe treatment. In practical terms, waste prevention requires designing synthetic pathways that minimize by-product formation, reduce auxiliary material consumption, and maximize product yield.

The pharmaceutical industry commonly uses Process Mass Intensity (PMI) as a key metric for waste prevention, calculated as the total mass of materials input per mass of product output [12] [14]. A lower PMI indicates higher process efficiency and less waste generation. Biocatalytic processes achieve superior PMI through several mechanisms: enzymatic specificity reduces by-product formation, aqueous reaction conditions eliminate organic solvent waste, and mild operating temperatures minimize energy-intensive heating/cooling requirements [15].

Quantitative Assessment of Waste Reduction

Biocatalysis demonstrates quantifiable advantages over traditional chemical synthesis in waste reduction. The following table compares representative metrics between conventional and biocatalytic processes for pharmaceutical intermediates:

Table 1: Waste Reduction Through Biocatalysis in Pharmaceutical Applications

| Process Metric | Traditional Chemical Synthesis | Biocatalytic Process | Reduction Achieved |

|---|---|---|---|

| Process Mass Intensity (PMI) | Often >100 kg/kg API [12] | Can reach <10 kg/kg API [1] | Up to 90% reduction |

| Organic Solvent Usage | High (multiple L/kg API) | Reduced by up to 85-90% [15] | 85-90% |

| Waste Management Costs | Significant disposal expenses | Up to 40% lower [15] | 40% |

| Energy Consumption | High (elevated T/P common) | Dramatically reduced (ambient T/P) [15] | Up to 80-90% |

A notable case study involves the synthesis of Edoxaban, an oral anticoagulant, where implementing an enzymatic route reduced organic solvent usage by 90%, cut raw material costs by 50%, and simplified manufacturing by reducing filtration steps from seven to three [15]. Similarly, Merck's biocatalytic synthesis of Sitagliptin reduced waste by 19% and eliminated a genotoxic intermediate [1].

Experimental Protocol: Measuring Process Mass Intensity

Objective: Quantify the waste prevention potential of a biocatalytic process by calculating its Process Mass Intensity.

Materials:

- Biocatalyst (whole cells or purified enzyme preparation)

- Substrates and reagents

- Aqueous reaction buffer

- Standard laboratory equipment (bioreactor, shake flasks, HPLC/UPLC)

Methodology:

- Process Setup: Conduct the biocatalytic reaction at optimal conditions (pH, temperature, agitation) in triplicate.

- Mass Documentation: Precisely weigh all input materials including water, substrates, catalysts, acids/bases for pH adjustment, and any extraction solvents.

- Product Quantification: Analyze reaction completion via HPLC/UPLC against validated standards.

- PMI Calculation: Apply the formula PMI = Total mass of inputs (kg) / Mass of product (kg)

- Comparative Analysis: Calculate PMI for traditional chemical synthesis route using literature or experimental data.

- Waste Reduction Percentage: Determine improvement using the formula: % Reduction = [(PMItraditional - PMIbiocatalytic) / PMI_traditional] × 100

Validation: Repeat experiments across multiple batches to establish statistical significance. Include lifecycle assessment where possible to account for catalyst production and waste treatment impacts.

Principle 2: Atom Economy

Theoretical Foundation

Atom economy, the second principle of green chemistry, requires that "synthetic methods should be designed to maximize incorporation of all materials used in the process into the final product" [12]. Developed by Barry Trost, this concept evaluates synthetic efficiency by calculating what proportion of reactant atoms become incorporated into the desired product versus being wasted as by-products [12].

Traditional efficiency metrics focused exclusively on reaction yield, which can be misleading. A reaction may achieve 100% yield while having poor atom economy if significant portions of reactant molecules are discarded as waste. Atom economy provides a more comprehensive assessment by evaluating the molecular efficiency of a synthetic route.

The fundamental calculation is: % Atom Economy = (FW of atoms utilized / FW of all reactants) × 100

Where FW represents formula weight. Biocatalysis enhances atom economy through multiple mechanisms: enzymes exhibit exceptional selectivity that minimizes side products, catalytic mechanisms avoid stoichiometric reagents, and cofactor recycling systems enable efficient reuse of reaction components [16].

Quantitative Analysis of Atom Economy

Recent advances in photobiocatalysis demonstrate exceptional atom economy achievements. In a 2025 study of light-driven cyanobacterial ene-reductions, researchers achieved an atom economy of 88% using photosynthetic cofactor regeneration, dramatically outperforming traditional sacrificial co-substrate systems (glucose: 49%; formic acid: 78%) [16].

Table 2: Atom Economy Comparison in Redox Biocatalysis

| Cofactor Regeneration System | Atom Economy | Key Advantages | Limitations |

|---|---|---|---|

| Photosynthetic (H₂O → O₂) | 88% [16] | Water as electron donor, self-renewing | Light penetration challenges |

| Formate/Formate Dehydrogenase | 78% [16] | Well-established, high compatibility | CO₂ generation, cost |

| Glucose/Glucose Dehydrogenase | 49% [16] | High driving force, widely used | Low atom economy, byproducts |

| Stoichiometric Chemical Reductants | Typically <30% | Simple implementation | High cost, poor atom economy |

The high atom economy of photosynthetic systems stems from using water as the ultimate electron donor, with light energy driving cofactor regeneration. This approach exemplifies how biocatalysis can integrate with renewable energy inputs to achieve nearly optimal atom utilization.

Experimental Protocol: Light-Driven Ene-Reduction with Cyanobacterial Whole-Cells

Objective: Implement and evaluate atom-efficient photobiocatalysis for ene-reduction reactions.

Materials:

- Recombinant Synechocystis sp. PCC 6803 expressing OYE3 ene-reductase

- Substrate (e.g., (R)-carvone or other prochiral alkene)

- Flat panel photobioreactor (1 cm optical path length)

- LED light source (specific wavelengths optimized for cyanobacteria)

- HPLC with chiral column for enantioselective analysis

- Dissolved oxygen probe

Methodology:

- Strain Preparation: Cultivate recombinant cyanobacteria in BG-11 medium under continuous illumination to mid-log phase.

- Cell Harvesting: Concentrate cells to high density (OD730 ≈ 20) via gentle centrifugation.

- Reaction Setup: Suspend cells in reaction buffer, add substrate to 50 mM final concentration in photobioreactor.

- Process Monitoring: Maintain constant illumination (≈100 μmol photons m⁻² s⁻¹), monitor dissolved oxygen, temperature (30°C), and pH (7.5).

- Sampling and Analysis: Collect samples periodically, extract with ethyl acetate, and analyze conversion and enantiomeric excess by chiral HPLC.

- Atom Economy Calculation: Determine % Atom Economy = (MW product / MW substrate) × 100

Key Optimization Parameters:

- Light intensity and wavelength composition

- Cell density balancing between biocatalyst concentration and light penetration

- Substrate concentration to minimize toxicity while maintaining efficient conversion

- Reaction duration (typically 6-10 hours for high yield)

Principle 3: Safer Design

Theoretical Foundation

The principles of "less hazardous chemical syntheses" and "designing safer chemicals" collectively establish that synthetic methods should use and generate substances with minimal toxicity to human health and the environment [12] [11]. This represents a two-fold approach: (1) selecting benign reagents and solvents, and (2) designing molecular products that minimize toxicity while maintaining function.

Biocatalysis inherently supports safer design through multiple mechanisms. Enzymes function optimally in aqueous systems at ambient temperatures, eliminating needs for hazardous organic solvents and energy-intensive conditions [15]. Their exquisite selectivity avoids generation of toxic byproducts, and enzyme biodegradability prevents environmental persistence [3]. Furthermore, biocatalytic routes often enable direct synthesis of enantiopure compounds, avoiding racemic mixtures that may contain toxic stereoisomers.

Implementation Strategies for Safer Design

Solvent Selection and Elimination

Biocatalysis enables a fundamental shift from organic solvents to aqueous reaction media. Where solvents remain necessary for substrate solubility or product recovery, green chemistry principles guide selection toward safer alternatives. Pharmaceutical companies like Pfizer and AstraZeneca have implemented solvent selection guides that rank options based on environmental, health, and safety criteria [14] [17].

Safer Solvent Implementation:

- Aqueous buffer systems: Ideal for most hydrolytic and redox biotransformations

- Green organic solvents: When required, select from ACS GCI Pharmaceutical Roundtable recommended solvents (e.g., 2-methyl-THF, cyclopentyl methyl ether, ethanol)

- Solvent-free systems: Implemented where substrates/products are liquids

- Bio-based solvents: Derived from renewable feedstocks with improved toxicity profiles

Renewable Feedstocks and Biodegradable Catalysts

Biocatalysis aligns with the green chemistry principle favoring renewable feedstocks over depletable resources [3]. Enzymes are produced via fermentation of agricultural products, reducing dependence on petrochemical feedstocks. Additionally, enzymes themselves are fully biodegradable, preventing catalyst persistence in the environment—a significant advantage over heavy metal catalysts.

Experimental Protocol: Solvent Replacement Assessment for Biocatalytic Reactions

Objective: Systematically evaluate and implement safer solvents in biocatalytic processes.

Materials:

- Purified enzyme or whole-cell biocatalyst

- Target substrate

- Candidate solvents (various classes based on green selection guides)

- Aqueous buffer systems

- GC-MS for solvent residue analysis

- Cytotoxicity assay kits (e.g., MTT assay)

Methodology:

- Solvent Selection: Compile candidate solvents using pharmaceutical industry green solvent guides (e.g., GSK, Pfizer, ACS GCI).

- Biocatalyst Compatibility Screening:

- Incubate biocatalyst with 10% (v/v) solvent in aqueous buffer

- Measure residual activity after 1-hour and 24-hour exposure

- Select solvents maintaining >80% initial activity

- Reaction Performance Assessment:

- Conduct biotransformations in biphasic systems with compatible solvents

- Compare conversion rates, yields, and product quality to reference systems

- Evaluate extraction efficiency for in situ product recovery

- Hazard Assessment:

- Document flammability, toxicity, and environmental impact data

- Test for extractable solvent residues in final product

- Evaluate solvent biodegradability using standard protocols

- Process Safety Evaluation:

- Assess waste stream composition and treatment requirements

- Compare process safety metrics (E-factor, PMI) to conventional processes

Decision Framework: Select solvent systems that simultaneously maintain biocatalyst activity, provide efficient reaction performance, and minimize environmental, health, and safety hazards.

The Scientist's Toolkit: Essential Research Reagents and Solutions

Successful implementation of green chemistry principles in biocatalysis requires specialized reagents and materials. The following table details essential components for developing waste-preventing, atom-economical, and safer biocatalytic processes:

Table 3: Essential Research Reagents for Green Biocatalysis

| Reagent Category | Specific Examples | Function in Green Biocatalysis | Implementation Notes |

|---|---|---|---|

| Ene-Reductases | OYE3, TsOYE variants [16] | C=C bond reduction with perfect atom economy | Photosynthetic cofactor regeneration enhances atom economy |

| Transaminases | ω-Transaminases [1] | Chiral amine synthesis without directing groups | Replaces stoichiometric chiral auxiliaries; reduces steps |

| Unspecific Peroxygenases | UPO enzymes [10] | Late-stage oxyfunctionalization | Superior total turnover numbers vs. P450s; reduces waste |

| Cofactor Recycling Systems | Formate dehydrogenase, glucose dehydrogenase [10] | NAD(P)H regeneration without stoichiometric reductants | Enables catalytic vs. stoichiometric cofactor usage |

| Whole-Cell Biocatalysts | Recombinant Synechocystis [16] | Self-regenerating cofactor systems | Combines biosynthesis and biotransformation in one pot |

| Immobilization Supports | EziG carriers, chitosan beads [3] | Enzyme stabilization and reuse | Reduces enzyme waste and process costs |

| Green Solvents | 2-MeTHF, CPME, limonene [1] | Safer reaction media | Renewable feedstocks; reduced toxicity and flammability |

Integrated Workflow and Future Perspectives

The relationship between green chemistry principles and biocatalytic implementations can be visualized as an integrated system where each principle guides specific technological developments that collectively advance sustainability goals.

Green Chemistry-Biocatalysis Integration

Future developments in biocatalysis will further enhance adherence to green chemistry principles. Artificial intelligence and machine learning are accelerating enzyme discovery and engineering, reducing development timelines from months to days [10]. The expanding toolbox of biocatalysts now includes enzymes for challenging transformations such as selective C-H activation, amide bond formation, and halogenation—reactions previously dominated by traditional chemistry with poorer environmental profiles [10] [14].

The integration of multiple enzymes into cascade processes represents a particularly promising direction, enabling complex syntheses in single pots without intermediate isolation. Such multi-enzyme systems dramatically reduce PMI while maximizing atom economy. As these technologies mature, biocatalysis will continue to displace traditional chemical processes, advancing the ultimate green chemistry goal of sustainable manufacturing across the chemical and pharmaceutical industries.

Enzymes, as nature's privileged biological catalysts, exhibit exceptional precision and efficiency by significantly accelerating reaction rates while operating under mild physiological conditions. These proteins achieve catalysis by binding to specific reactant molecules, known as substrates, at defined regions called active sites, facilitating their conversion into products through a substantial reduction in the activation energy required for the reaction [18] [19]. The inherent chirality, biodegradability, and biocompatibility of enzymes position them as ideal catalysts for advancing sustainable manufacturing paradigms within the frameworks of green chemistry and industrial biotechnology [20] [3]. This whitepaper explores the fundamental lock-and-key principle of enzyme action and delineates how this precise mechanism underpins the significant environmental and economic advantages of biocatalysis, thereby supporting the transition toward a circular bio-based economy.

The Lock-and-Key Model: A Foundation of Specificity

Historical Principle and Molecular Complementarity

Proposed in 1894 by the German scientist Emil Fischer, the lock-and-key model provides a foundational theory for understanding enzyme specificity [18]. This model posits a static, pre-defined complementarity between an enzyme's active site and its substrate. The enzyme, representing the "lock," possesses an active site with a rigid, three-dimensional geometry and chemical character that perfectly matches that of the substrate, the "key" [18] [19]. This precise steric and chemical fit is essential for selective substrate binding and is a key determinant of the enzyme's catalytic power. The active site typically constitutes a small portion (about 10-20%) of the enzyme's total volume and is formed by a unique combination of amino acid residues whose side chains create the specific microenvironment necessary for substrate binding and catalysis [18].

Formation of the Enzyme-Substrate Complex

The catalytic cycle begins with the reversible binding of the substrate to the enzyme's active site to form the enzyme-substrate complex (ES). This binding is stabilized by multiple non-covalent interactions, including:

- Hydrogen bonds

- Hydrophobic interactions

- Ionic interactions

- Van der Waals forces [18]

Within this complex, the substrate is orientated optimally, and the local chemical environment of the active site lowers the activation energy for the reaction, promoting the breaking and forming of chemical bonds. Following the transformation, the products are released, and the unchanged enzyme is regenerated, ready to bind another substrate molecule [18] [19].

Limitations and Evolving Understanding

While the lock-and-key model successfully explains the high degree of specificity observed in many enzymes, it has notable limitations. The model depicts the enzyme as a completely rigid structure, which fails to account for the observed conformational changes that often occur upon substrate binding [18] [19]. Furthermore, it does not adequately explain how some enzymes can catalyze reactions for multiple, similarly structured substrates (e.g., lipases or proteases). These limitations led to the development of the induced fit model, which refines the original concept by proposing that the active site is more flexible and can adjust its conformation to better accommodate the substrate [19]. Despite its limitations, the lock-and-key model remains a critical conceptual tool for understanding the origin of enzymatic specificity.

The following diagram illustrates the core concept of the lock-and-key mechanism and its integration with modern enzyme engineering approaches.

Quantitative Analysis of Enzyme Kinetics

Michaelis-Menten Fundamentals

The efficiency of enzyme-catalyzed reactions is quantitatively described by Michaelis-Menten kinetics, a model that relates reaction velocity (v) to substrate concentration [a] [21] [22]. The central equation is:

( v = \frac{V{max}[a]}{Km + [a]} )

Where:

- ( v ) is the initial reaction velocity.

- ( V_{max} ) is the maximum reaction velocity, achieved when the enzyme is fully saturated with substrate.

- ( Km ) is the Michaelis constant, defined as the substrate concentration at which the reaction velocity is half of ( V{max} ). It is an inverse measure of the enzyme's affinity for its substrate; a lower ( K_m ) indicates higher affinity.

- ( k_{cat} ) is the turnover number, representing the maximum number of substrate molecules converted to product per enzyme molecule per unit time [21] [22].

Key Kinetic Parameters and Their Significance

The ratio ( k{cat}/Km ) is known as the specificity constant, which reflects the catalytic efficiency of an enzyme toward a particular substrate. It has units of M⁻¹s⁻¹ and defines the enzyme's performance at low substrate concentrations. A higher specificity constant indicates a more efficient enzyme [22].

Table 1: Kinetic Parameters of Representative Enzymes

| Enzyme | ( K_m ) (M) | ( k_{cat} ) (s⁻¹) | ( k{cat}/Km ) (M⁻¹s⁻¹) |

|---|---|---|---|

| Chymotrypsin | ( 1.5 \times 10^{-2} ) | 0.14 | 9.3 |

| Pepsin | ( 3.0 \times 10^{-4} ) | 0.50 | ( 1.7 \times 10^{3} ) |

| Ribonuclease | ( 7.9 \times 10^{-3} ) | ( 7.9 \times 10^{2} ) | ( 1.0 \times 10^{5} ) |

| Carbonic Anhydrase | ( 2.6 \times 10^{-2} ) | ( 4.0 \times 10^{5} ) | ( 1.5 \times 10^{7} ) |

| Fumarase | ( 5.0 \times 10^{-6} ) | ( 8.0 \times 10^{2} ) | ( 1.6 \times 10^{8} ) |

Source: Adapted from [22]

Green Advantages of Enzymatic Catalysis

The precision of enzyme catalysis, rooted in mechanisms like the lock-and-key model, translates directly into significant sustainable advantages for chemical manufacturing. These benefits align closely with the principles of green chemistry.

Environmental and Economic Benefits

- High Selectivity and Atom Economy: Enzymes exhibit exquisite stereospecificity, enabling the production of single enantiomers of chiral compounds—a critical requirement in pharmaceutical synthesis—without generating stereoisomeric waste. This high fidelity minimizes downstream purification needs and improves atom economy [20] [3].

- Mild Reaction Conditions: Biocatalysis typically occurs under mild temperatures, near-neutral pH, and in aqueous solvents, drastically reducing the energy consumption associated with high-temperature and high-pressure processes common in traditional chemistry [3] [23].

- Reduced Environmental Footprint: Enzymes are biodegradable and derived from renewable resources. Their use avoids the need for heavy metal catalysts and hazardous reagents, minimizing the generation of toxic waste [3]. The E-factor (kg waste/kg product) for enzymatic processes is often substantially lower than for conventional chemical routes [20] [3].

Alignment with Green Chemistry Principles

Enzyme catalysis adheres to most of the Twelve Principles of Green Chemistry. A recent analysis notes that biocatalysis is in accordance with at least ten of these principles, with the remaining two being concerned with final product design rather than the process itself [3].

Table 2: Alignment of Enzyme Catalysis with Green Chemistry Principles

| Green Chemistry Principle | Manifestation in Biocatalysis |

|---|---|

| Prevention of Waste | High selectivity minimizes by-products, lowering the E-factor [3]. |

| Atom Economy | Specificity ensures most substrate atoms are incorporated into the desired product [20]. |

| Less Hazardous Syntheses | Non-toxic catalysts (enzymes) and mild conditions replace hazardous reagents [3]. |

| Design for Energy Efficiency | Reactions performed at ambient temperature and pressure [23]. |

| Use of Renewable Feedstocks | Enzymes themselves are produced from renewable biobased resources [20]. |

| Reduce Derivatives | High selectivity often eliminates the need for protecting groups [3]. |

| Catalysis | Enzymes are biological catalysts that are not consumed in the reaction. |

| Design for Degradation | Enzyme proteins are biodegradable [3]. |

Advanced Applications and Experimental Protocols

Enzyme Engineering for Enhanced Performance

The intrinsic properties of wild-type enzymes can be optimized for industrial processes using advanced protein engineering techniques. Directed evolution, which involves generating random mutations and screening for improved variants, and rational design, based on structural knowledge to make targeted mutations, are powerful methods for creating fit-for-purpose biocatalysts [23]. For instance, engineered transaminases have been developed that exhibit a broader substrate range, higher thermostability, and tolerance to organic solvents, achieving up to 95% conversion in the asymmetric synthesis of chiral amines—key building blocks for pharmaceuticals—under gentle, environmentally friendly conditions [23].

Experimental Protocol: Enzyme Immobilization in Flow Biocatalysis

Immobilization is a key strategy for enhancing enzyme stability and enabling reuse, which is critical for economic viability. A modern protocol for creating a continuous-flow biocatalytic system is outlined below.

Objective: To immobilize an enzyme (e.g., Soy Bean Peroxidase) within a monolithic porous layer open tubular (monoPLOT) capillary reactor to achieve continuous sulfoxidation with minimal backpressure [24].

Materials and Reagents:

- Enzyme: Soy Bean Peroxidase.

- Capillary: Fused silica capillary (100 μm internal diameter).

- Monomer/Linker: Vinyl azlactone (acts as a linker for enzyme attachment).

- Substrate: Thioanisole.

- Initiation System: Chemicals for thermal or photo-initiated polymerization (e.g., AIBN).

- Pumping System: Syringe pump for precise flow control.

Procedure:

- Monolith Synthesis: Synthesize a porous polymer monolith in situ within the capillary using vinyl azlactone as a co-monomer. Precisely control the polymerization to form only a thin layer on the capillary walls, leaving the central channel open. This "monoPLOT" structure eliminates backpressure issues common in packed-bed reactors [24].

- Enzyme Immobilization: Pass a solution of Soy Bean Peroxidase through the functionalized monoPLOT capillary. The enzyme forms covalent bonds with the azlactone groups on the monolith surface, leading to its stable immobilization.

- Continuous Flow Reaction: Continuously pump a solution of thioanisole in a suitable buffer through the enzyme-loaded reactor.

- Process Monitoring: Analyze the effluent stream (e.g., by HPLC) to monitor the conversion of thioanisole to its sulfoxide product. The target is >99% conversion under optimized flow conditions.

- Stability and Reusability Assessment: Operate the reactor continuously over multiple cycles (e.g., 10 cycles) to assess the operational stability of the immobilized enzyme. Activity is typically retained for multiple runs before a significant decline is observed [24].

The workflow for this continuous flow biocatalysis experiment is summarized below.

The Scientist's Toolkit: Essential Research Reagents

Table 3: Key Reagents for Enzyme Engineering and Biocatalysis Research

| Reagent / Material | Function in Research |

|---|---|

| Vinyl Azlactone | A functional monomer used to create reactive surfaces for covalent enzyme immobilization on supports like monoliths [24]. |

| Engineered Transaminases | Tailored biocatalysts for the asymmetric synthesis of chiral amines, offering high enantioselectivity and stability [23]. |

| Metal–Organic Frameworks (MOFs) | Porous crystalline materials used as sustainable supports for enzyme immobilization, enhancing stability and reusability [25]. |

| Monolithic Porous Layer Open Tubular (monoPLOT) Capillaries | A support structure for flow biocatalysis that minimizes backpressure, enabling efficient continuous processing [24]. |

| Cofactors (e.g., NADH, PLP) | Essential non-protein molecules required for the activity of many enzymes (apoenzymes); must be supplied or regenerated in situ [18] [19]. |

The lock-and-key model, while a simplified representation, provides an essential framework for understanding the molecular basis of enzyme specificity. This inherent precision is the foundation upon which the green advantages of biocatalysis are built. As the chemical industry seeks to transition away from fossil-based resources and reduce its environmental footprint, enzymes offer a powerful technological solution. They enable efficient, selective, and low-waste manufacturing processes that align with the principles of green chemistry and support the United Nations Sustainable Development Goals [20].

Future progress will be driven by advances in enzyme engineering through directed evolution and rational design, allowing for the creation of robust biocatalysts tailored to specific industrial needs [23]. The integration of biocatalysis with continuous flow systems and novel immobilization techniques, such as those using Metal-Organic Frameworks (MOFs), will further enhance process efficiency and scalability [25] [24]. By fully leveraging the precision of nature's catalysts, researchers and industry professionals can engineer a more sustainable and economically viable future for chemical synthesis.

The chemical and pharmaceutical industries are undergoing a fundamental transformation, moving from traditional waste management strategies to an inherently safer and more sustainable approach to process design. This shift represents a critical evolution from reactive pollution control to proactive pollution prevention at the molecular level [1] [26]. Historically, traditional chemical manufacturing operated on principles developed during the early industrial revolution, where waste generation was accepted as inevitable, and the focus remained on "end-of-pipe" treatment—managing hazardous substances after they were created [1]. This approach has proven economically and environmentally unsustainable, particularly in sectors like pharmaceutical manufacturing where the E-factor (environmental factor) often exceeded 100, meaning producing one kilogram of product generated over 100 kilograms of waste [1].

Green chemistry, established through the twelve principles defined by Paul Anastas and John Warner in 1998, flips this paradigm by designing sustainability into processes from inception [1] [27]. The core philosophy is simple yet revolutionary: it is fundamentally superior to prevent waste than to treat or clean it up after it is formed [26]. This proactive framework now drives industry-wide transformation across manufacturing sectors, guided by the recognition that preventing waste is more economical than managing it [1]. Within this transformation, biocatalysis—the use of natural catalysts like enzymes to perform chemical transformations—has emerged as a cornerstone technology that embodies the principles of inherently safer design, offering a pathway to dramatically reduce the environmental footprint of industrial processes while maintaining economic viability [1] [15].

The Foundation: Principles of Green Chemistry

The twelve principles of green chemistry provide a comprehensive framework for designing chemical products and processes that reduce or eliminate the use and generation of hazardous substances [27] [26]. These principles collectively guide researchers and engineers toward developing chemical processes that are inherently safer and more sustainable across their entire lifecycle.

Core Principles Guiding Inherently Safer Design

For researchers in biocatalysis, several principles are particularly relevant. Atom economy (Principle 2) emphasizes maximizing the incorporation of all starting materials into the final product, thereby minimizing byproduct formation [26]. Catalysis (Principle 9) advocates for using selective catalytic reagents rather than stoichiometric ones, as catalysts participate in reactions without being consumed, dramatically reducing material requirements and waste generation [1] [28]. Safer solvents and auxiliaries (Principle 5) encourages minimizing or eliminating auxiliary substances or employing innocuous alternatives when necessary [27]. Design for energy efficiency (Principle 6) recognizes that energy requirements should be minimized, with synthetic methods conducted at ambient temperature and pressure whenever possible [27] [15].

The following table summarizes how these principles translate from theoretical concepts to practical implementation in industrial biocatalysis:

Table 1: Green Chemistry Principles in Biocatalysis Research and Industrial Application

| Principle | Theoretical Concept | Implementation in Biocatalysis |

|---|---|---|

| Prevention | Prevent waste rather than treat it after creation [26] | Design selective enzymatic reactions that minimize byproducts [1] |

| Atom Economy | Maximize material incorporation into final product [27] | High-specificity enzyme reactions incorporate more starting atoms into products [15] |

| Less Hazardous Synthesis | Use/generate substances with minimal toxicity [27] | Enzymes are biodegradable catalysts; reactions often avoid toxic reagents [15] |

| Safer Solvents | Minimize auxiliary substance use [27] | Reactions often proceed in aqueous environments [1] [15] |

| Energy Efficiency | Conduct reactions at ambient conditions [27] | Enzymes operate at room temperature and atmospheric pressure [15] |

| Catalysis | Use catalytic rather than stoichiometric reagents [1] | Enzymes are biological catalysts operating with high efficiency [1] [28] |

Quantitative Metrics: Measuring the Shift

The transition from end-of-pipe treatment to inherently safer design requires robust metrics to quantify environmental and economic improvements. Standardized metrics enable objective comparison between traditional and green alternative processes and help track continuous improvement [1].

Key Performance Indicators for Green Chemistry

The pharmaceutical industry, a leader in adopting green chemistry principles, employs several key metrics to evaluate process efficiency and environmental impact [1]. These metrics provide tangible evidence of the benefits achieved through the paradigm shift toward inherently safer design, particularly through biocatalytic processes.

Table 2: Key Metrics for Evaluating Green Chemistry Processes in Pharmaceutical Manufacturing

| Metric | What It Measures | Traditional Process | Green Chemistry Target |

|---|---|---|---|

| E-factor | Mass waste per mass product [1] | >100 for pharma [1] | <5 for specialties [1] |

| Atom Economy | Efficiency of molecular incorporation [26] | Varies; often low for multi-step syntheses | >70% considered good [1] |

| Process Mass Intensity (PMI) | Total mass input per product mass [1] | Often exceeds 100 for pharma [28] | <20 for pharmaceuticals [1] |

| Solvent Intensity | Solvent mass per product mass [1] | High (solvents account for >60% of processed materials) [29] | <10 target [1] |

The implementation of green chemistry principles, particularly through biocatalysis, has demonstrated dramatic improvements across these metrics. For instance, the pharmaceutical industry has documented reductions in solvent use by up to 85% and cuts in waste management costs by up to 40% through enzyme-based processes [15]. Furthermore, companies report 30-50% cost reductions alongside environmental improvements when implementing biocatalytic routes [1].

Biocatalysis: A Cornerstone of Inherently Safer Design

Biocatalysis utilizes natural catalysts—primarily enzymes or whole cells—to perform specific chemical transformations with extraordinary precision and efficiency. This approach exemplifies multiple green chemistry principles simultaneously, making it a transformative technology for sustainable manufacturing [1] [15].

Fundamental Advantages of Enzymatic Systems

Enzymes offer a combination of properties that make them ideal for inherently safer chemical design. They function effectively at room temperature and atmospheric pressure, dramatically reducing energy requirements compared to traditional chemical synthesis that often requires high temperatures and pressures [15]. They exhibit exceptional selectivity, including substrate specificity, regioselectivity, and stereoselectivity, which minimizes unwanted side reactions and by-products, thereby reducing purification needs and waste generation [1] [15]. Furthermore, enzymatic processes typically occur in aqueous environments, eliminating or reducing the need for hazardous organic solvents [1]. Being natural proteins, enzymes are also inherently biodegradable and pose minimal environmental persistence concerns [15].

The following DOT visualization illustrates the conceptual shift from traditional linear processes to integrated, safer design centered around biocatalysis, highlighting the reduction of waste and hazardous materials.

Enzyme Classes and Their Industrial Applications

The diversity of available enzymes enables manufacturers to address a wide range of chemical transformation challenges while maintaining environmental and economic benefits. Different enzyme classes support various industrial reactions, each contributing unique capabilities to cleaner, more targeted chemical transformations [15].

Table 3: Major Enzyme Classes in Green Chemistry Applications

| Enzyme Type | Function | Industrial Applications | Green Chemistry Benefits |

|---|---|---|---|

| Hydrolases | Break down molecules using water as a nucleophile [15] | Food processing, pharmaceuticals, fine chemicals [15] | Water-based reactions, mild conditions, high selectivity [15] |

| Lipases | Catalyze hydrolysis and synthesis of ester bonds in fats and oils [15] | Biodiesel production, food industry, oleochemicals [15] | Renewable feedstock processing, reduced waste [15] |

| Proteases | Cleave peptide bonds in proteins [15] | Detergents, leather processing, food processing [15] | Replace harsh chemicals, biodegradable products [15] |

| Oxidoreductases | Catalyze oxidation and reduction reactions [15] | Chemical synthesis, biofuels, environmental remediation [15] | Eliminate toxic oxidants/reductants, mild conditions [15] |

Experimental Protocols in Biocatalysis Research

Implementing a biocatalytic process requires a systematic approach from enzyme discovery and engineering to process optimization. The following methodologies represent current best practices in the field.

Protocol 1: Development of an Enzymatic Synthesis Route

The development of an enzymatic synthesis route for Edoxaban, a critical oral anticoagulant, demonstrates the transformative potential of green chemistry approaches [15]. This case study provides a template for developing similar biocatalytic processes.

Objective: Replace traditional multi-step chemical synthesis with a more efficient, selective, and environmentally friendly enzymatic process.

Materials and Reagents:

- Enzyme Library: Commercially available or metagenomically sourced hydrolases/transaminases for screening.

- Analytical Standards: Authentic samples of starting materials, intermediates, and final product for HPLC/MS calibration.

- Green Solvents: Water, bio-based solvents (2-methyltetrahydrofuran, cyclopentyl methyl ether), supercritical CO₂.

- Reagents: Pharmaceutical-grade starting materials, buffer components (phosphate, carbonate), co-factors (NADH, PLP) if required.

Methodology:

- Enzyme Screening: Perform high-throughput screening of enzyme libraries against the target transformation using microtiter plates. Monitor conversion and enantioselectivity via HPLC or GC.

- Reaction Optimization: Systematically vary key parameters (pH, temperature, substrate concentration, enzyme loading) using Design of Experiments (DoE) methodologies to identify optimal conditions.

- Solvent Engineering: Evaluate process performance in various green solvent/water mixtures and solvent-free systems to identify the most environmentally benign reaction medium.

- Biocatalyst Engineering: Employ directed evolution or rational design to improve enzyme activity, stability, and solvent tolerance if the wild-type enzyme performance is insufficient.

- Process Intensification: Transition from batch to continuous flow reactor systems to enhance mass transfer, improve temperature control, and enable integrated downstream processing.

- Lifecycle Assessment: Conduct a full lifecycle assessment to quantify environmental and economic benefits compared to the traditional process.

Outcome: The implemented enzymatic process for Edoxaban resulted in a 90% reduction in organic solvent usage, a 50% decrease in raw material costs, and a reduction of filtration steps from 7 to 3, significantly simplifying manufacturing operations [15].

Protocol 2: Mechanoenzymatic Synthesis Using Solvent-Free Grinding

Mechanochemistry, which uses mechanical energy to drive reactions, can be combined with biocatalysis for truly solvent-free synthesis, representing a frontier in green chemistry research [6].

Objective: Develop a solvent-free enzymatic process using ball-milling technology for the synthesis of active pharmaceutical ingredients (APIs) or intermediates.

Materials and Reagents:

- Planetary Ball Mill: Equipment capable of controlled rotational speeds and multiple grinding jars.

- Grinding Media: Stainless steel, zirconium oxide, or ceramic balls of varying diameters.

- Biocatalyst: Immobilized enzyme preparation (e.g., cross-linked enzyme aggregates - CLEAs) to enhance mechanical stability.

- Substrates: Solid forms of reaction starting materials, preferably with controlled particle size.

Methodology:

- Biocatalyst Preparation: Prepare immobilized enzyme forms, such as CLEAs or enzymes immobilized on solid supports, to withstand the shear forces of ball milling.

- Charge Preparation: Weigh solid substrates and immobilized biocatalyst directly into the grinding jar along with the grinding balls.

- Reaction Execution: Run the planetary ball mill at optimized rotational speed and time. Control temperature using cooled milling jars if necessary.

- Process Monitoring: Periodically stop milling to collect small samples for analysis (e.g., conversion via HPLC). Alternatively, use in-situ Raman spectroscopy for real-time monitoring.

- Product Recovery: After reaction completion, separate the product from the catalyst and grinding balls via sieving. The immobilized catalyst can often be reused directly for subsequent batches.

- Purification: Purify the product using standard techniques, noting the significantly reduced solvent volume required compared to solution-based synthesis.

The following DOT visualization maps this experimental workflow, showing the key stages from catalyst preparation to final purification.

The Scientist's Toolkit: Essential Research Reagents & Materials

Successful implementation of biocatalysis requires specific reagents and materials tailored to enzymatic processes. The following table details key solutions for researchers in this field.

Table 4: Essential Research Reagents and Materials for Biocatalysis

| Reagent/Material | Function/Application | Green Chemistry Advantage |

|---|---|---|

| Immobilized Enzymes (CLEAs, EziG) | Heterogenized biocatalysts for enhanced stability and reusability [28] | Enables catalyst recycling, reduces process cost, facilitates continuous flow processing [28] |

| Deep Eutectic Solvents (DES) | Customizable, biodegradable solvents for extraction and reaction media [6] | Low-toxicity, bio-based alternative to conventional organic solvents [6] |

| Cofactor Recycling Systems | Regenerates expensive cofactors (NADH, PLP) in situ [28] | Makes oxidative and reductive biocatalysis economically viable, avoids stoichiometric waste [28] |

| Bio-Based Solvents (Cyrene, 2-MeTHF) | Renewable solvents derived from biomass [28] | Reduce reliance on petrochemical feedstocks, often improved toxicological profiles [28] |

| Engineered Whole Cells | Living catalysts containing optimized enzymatic pathways [28] | Self-regenerating catalysts, can perform multi-step cascades without intermediate isolation [28] |

Future Outlook & Challenges

The adoption of green chemistry principles, particularly biocatalysis, will continue to accelerate, driven by regulatory pressure, economic incentives, and technological advances [1]. Emerging drivers include regulatory mandates requiring lifecycle environmental assessments, carbon pricing mechanisms, and the integration of artificial intelligence to accelerate green process discovery [1] [6]. The EU Chemical Strategy for Sustainability and its Safe and Sustainable by Design (SSbD) framework exemplifies this regulatory push, creating a structured approach to assess the safety and sustainability of novel chemicals and synthesis processes throughout their lifecycle [30].

Despite clear benefits, the widespread adoption of inherently safer design faces significant technical and operational challenges. These include capital investment requirements for new equipment, technical performance gaps for some chemical transformations, supply chain immaturity for renewable feedstocks, and workforce skill gaps requiring training in new techniques [1]. Furthermore, the high specificity of enzymes, while advantageous, can require extensive screening and optimization to match enzymes to specific substrates [15]. Overcoming these barriers will require continued multidisciplinary collaboration between experts in chemistry, chemical engineering, toxicology, ecotoxicology, and lifecycle assessment [30].

The industrial shift from end-of-pipe treatment to inherently safer process design represents both an environmental imperative and a strategic business advantage. By embracing green chemistry principles and leveraging advanced biocatalytic solutions, researchers and drug development professionals can lead this transformation, creating a more sustainable and economically viable future for the chemical and pharmaceutical industries.

Implementing Biocatalysis: Enzyme Engineering, Cascade Reactions, and Industrial Applications

The global shift toward sustainable industrial processes has positioned enzyme engineering as a cornerstone of green chemistry in biocatalysis research. Green chemistry principles prioritize waste reduction, energy efficiency, and the use of safer solvents, aligning perfectly with the inherent advantages of enzymatic processes [15]. Engineered enzymes now serve as powerful tools for achieving these sustainability goals across industries, from pharmaceuticals to biofuels, by enabling reactions under mild conditions with exceptional selectivity [31] [15].

The expansion of the global enzyme engineering market, projected to grow significantly in coming years, reflects the increasing adoption of these technologies [32] [33] [34]. This growth is largely driven by innovations in CRISPR technology, synthetic biology, and computational methods that allow for precise enzyme modifications tailored to specific industrial applications [32]. For researchers and drug development professionals, mastering directed evolution and rational design has become essential for developing next-generation biocatalysts that combine industrial robustness with environmental responsibility.

Core Enzyme Engineering Strategies

Directed Evolution

Directed evolution mimics natural selection in laboratory settings to develop enzymes with enhanced properties. This method involves iterative rounds of mutagenesis and screening to identify variants with improved catalytic efficiency, stability, or substrate specificity [35]. Unlike rational design, directed evolution does not require comprehensive knowledge of enzyme structure-function relationships, making it particularly valuable for optimizing enzymes with complex or unknown structural features.

A recent application in cardiac drug synthesis demonstrates the power of this approach. Through directed evolution, researchers engineered cytochrome P450 variants that achieved 97% substrate conversion efficiency for pharmaceutical intermediates, significantly outperforming wild-type enzymes [35]. The process typically involves:

- Creating genetic diversity through random mutagenesis, targeted mutagenesis, or gene recombination

- Expressing mutant libraries in suitable host systems (e.g., E. coli, yeast)

- High-throughput screening to identify improved variants using fluorescence-based assays, microfluidics, or selection systems [35] [10]

Directed evolution has been revolutionized by artificial intelligence and machine learning, which can predict beneficial mutations from large datasets, reducing experimental workload and accelerating development timelines [10]. Modern platforms can now complete rounds of directed evolution within 7-14 days, meeting pharmaceutical industry demands for rapid catalyst development [10].

Rational Design

Rational design employs structural knowledge and computational analysis to make precise, targeted modifications to enzyme structures. This approach requires detailed understanding of the enzyme's active site, catalytic mechanism, and structure-function relationships to predict mutations that will enhance desired properties [32] [31].

Key rational design strategies include: