Nature's Nano-Factories

How Enzymes are Revolutionizing Plastic Creation

Contents

Forget harsh chemicals and scorching heat. Imagine crafting tomorrow's plastics in a gentle, biological ballet, guided by nature's own master chemists: enzymes.

Welcome to the fascinating world of biocatalysis in polymer science, where biological molecules are harnessed to build the materials of our future sustainably and precisely. As we grapple with plastic pollution and the environmental toll of traditional manufacturing, this field offers a beacon of hope – a way to create essential polymers using cleaner, greener, and smarter methods inspired by life itself.

Unlocking the Power of Biological Catalysts

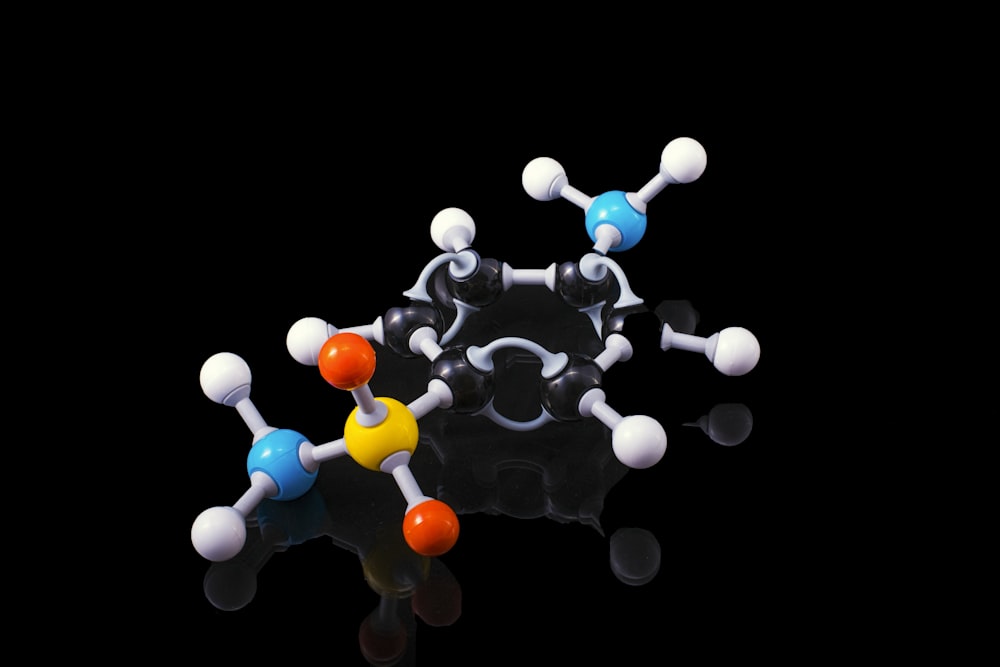

At its heart, biocatalysis uses enzymes – incredibly efficient and specific proteins evolved by nature over millennia – to speed up chemical reactions. Think of them as molecular machines, perfectly shaped to fit specific starting materials (substrates) and transform them into desired products under mild conditions (like room temperature and neutral pH). In polymer science, this means:

Building Blocks

Enzymes can stitch small molecules (monomers) together into long polymer chains (polymerization).

Precision Tailoring

They can modify existing polymers, adding specific functional groups or altering their structure to enhance properties like biodegradability or biocompatibility.

Breaking Down

Enzymes (like lipases and esterases) are nature's recyclers, capable of breaking down polymers (depolymerization), crucial for recycling or creating monomers from waste.

Why the Excitement?

- Sustainability: Dramatically reduces energy consumption, eliminates toxic metal catalysts, and uses renewable feedstocks.

- Precision: Enzymes offer exceptional control over polymer structure (chain length, tacticity, composition), leading to materials with superior properties.

- Green Chemistry: Operates under mild, aqueous conditions, minimizing waste and hazardous byproducts.

Biocompatibility & Biodegradability

Enzymes naturally work in biological systems, making them ideal for creating polymers for medical implants, drug delivery, or environmentally friendly plastics designed to break down safely.

Recent Frontiers

Scientists are pushing boundaries with:

Enzyme Engineering

Tweaking enzyme structures to make them faster, more stable, or able to work with non-natural monomers.

Novel Reactions

Discovering enzymes that catalyze entirely new types of polymer-forming reactions.

Combined Approaches

Integrating biocatalysis with traditional chemical catalysis ("chemobiocatalysis") for even greater versatility.

Spotlight Experiment: Enzymatic Synthesis of Biodegradable Polycaprolactone (PCL)

One groundbreaking area is the enzyme-catalyzed synthesis of polycaprolactone (PCL), a biodegradable polyester used in medical sutures, drug delivery systems, and compostable packaging. Traditional synthesis requires high temperatures and metal catalysts like tin octoate, leaving trace residues. Biocatalysis offers a cleaner alternative.

The Experiment: Lipase-Catalyzed Ring-Opening Polymerization (ROP)

- Goal: Synthesize high-molecular-weight PCL using a lipase enzyme under mild conditions.

- Key Enzyme: Candida antarctica Lipase B (CALB), often immobilized on beads (e.g., Novozym 435) for reusability.

- Monomer: ε-Caprolactone (a ring-shaped molecule).

Methodology: A Step-by-Step Dance

- Molecular Weight (Mw, Mn): Measured using Gel Permeation Chromatography (GPC).

- Conversion: Determined by weighing the purified polymer or using NMR to measure remaining monomer.

- Structure: Confirmed using Nuclear Magnetic Resonance (NMR) spectroscopy.

- Thermal Properties: Analyzed using Differential Scanning Calorimetry (DSC) for melting/crystallization points.

Results and Analysis: A Green Success Story

This biocatalytic approach consistently produces PCL with:

- High Molecular Weights: Comparable to or exceeding those achieved with traditional metal catalysts

- High Monomer Conversion: Often exceeding 95%

- Controlled Structure: Enzymes offer excellent control over the polymer chain ends and microstructure

Minimal Residues

The final polymer contains only trace amounts of the benign enzyme protein, unlike potentially toxic metal residues from conventional methods.

Scientific Importance

This experiment demonstrated that complex polymer synthesis can be achieved efficiently under mild, green conditions using biological catalysts. It proved that enzymes are not limited to small molecules but can handle the demanding chemistry of chain growth. This paved the way for synthesizing a wide range of biodegradable and biocompatible polyesters for medical and environmental applications using sustainable methods.

Data Tables

Table 1: Typical Results for CALB-Catalyzed PCL Synthesis

| Reaction Time (hours) | Temperature (°C) | Initiator Used? | Monomer Conversion (%) | Weight-Average Molecular Weight (Mw) | Dispersity (Ð = Mw/Mn) |

|---|---|---|---|---|---|

| 24 | 60 | Yes (BnOH) | 85% | 35,000 | 1.8 |

| 48 | 70 | No | 92% | 48,000 | 1.9 |

| 72 | 65 | Yes (1,4-BDO) | >99% | 72,000 | 2.1 |

Table 2: Properties Comparison

| Property | Biocatalytic PCL (CALB) | Conventional PCL (Sn(Oct)₂) |

|---|---|---|

| Melting Point (Tm) | ~55-60°C | ~55-60°C |

| Crystallinity | Moderate (~50%) | Moderate (~50%) |

| Biodegradation Rate | Comparable | Comparable |

| Catalyst Residue | Trace Protein | Trace Tin Compounds |

| Synthesis Temperature | 60-70°C | 120-180°C |

| Catalyst Toxicity Profile | Low | Moderate/Concern |

Table 3: Enzyme Performance

| Enzyme Form | Relative Activity* | Reusability (Cycles) |

|---|---|---|

| Free CALB (in solution) | High | Very Low (1-2) |

| CALB Immobilized (Novozym 435) | Very High | High (5-10+) |

| Genetically Engineered CALB | Variable (Often ↑) | Moderate |

| Crude Cell Extract (Lipase) | Low-Moderate | Very Low |

Key Insight: Immobilization is often essential for practical biocatalysis in polymer synthesis, enabling enzyme recovery and reuse, despite a higher initial cost.

The Scientist's Toolkit: Key Reagents for Enzymatic Polymerization

Here's a look at some essential components in the biocatalytic polymer chemist's arsenal, particularly for experiments like the PCL synthesis described:

Research Reagents for Biocatalytic Polymerization

| Research Reagent Solution | Function in Biocatalytic Polymerization | Example in PCL Synthesis |

|---|---|---|

| Enzyme Catalyst | The biological workhorse that accelerates the polymerization reaction with high specificity. | Candida antarctica Lipase B (CALB), often immobilized (Novozym 435). |

| Monomer | The small molecule building blocks that link together to form the polymer chain. | ε-Caprolactone (cyclic ester monomer). |

| Initiator | A molecule (often an alcohol or amine) that reacts with the enzyme-monomer complex to start the polymer chain growth. | Benzyl Alcohol (BnOH), 1,4-Butanediol (1,4-BDO). |

| Solvent (Optional) | Used to dissolve reactants or control viscosity. Ideally inert and non-disruptive to enzyme activity. | Toluene, Diphenyl Ether. Often avoided (solvent-free). |

| Immobilization Support | A solid material (e.g., resin, silica) to which the enzyme is attached. Enables easy recovery and reuse. | Acrylic resin beads (e.g., for Novozym 435). |

| Buffer (Rarely) | Used to maintain specific pH if crucial for enzyme stability (less common in solvent-free polyester ROP). | Phosphate buffer (pH 7.0). |

| Purification Solvents | Used to isolate and clean the final polymer product. | Chloroform (dissolution), Methanol (precipitation). |

Shaping a Sustainable Polymer Future

Biocatalysis in polymer science is no longer just a laboratory curiosity; it's rapidly evolving into a viable, sustainable manufacturing paradigm.

By harnessing the exquisite power of enzymes, scientists are learning to build complex, high-performance materials with unprecedented precision and minimal environmental footprint. From biodegradable plastics that safely return to nature, to ultra-pure polymers for life-saving medical devices, the potential applications are vast and transformative.

While challenges remain – such as further improving enzyme stability, cost-effectiveness for large-scale production, and expanding the range of compatible monomers – the progress is undeniable. The gentle clinking of enzymes building polymers at room temperature heralds a quieter, cleaner, and more sustainable revolution in materials science, proving that sometimes, the most powerful solutions are found by looking to nature's own molecular blueprints. The future of plastics is being written, one enzymatic reaction at a time.