Optimizing Multi-Enzyme Cascades: A Comprehensive Design of Experiments (DoE) Guide for Biomedical Researchers

This article provides a complete roadmap for applying Design of Experiments (DoE) to optimize complex multi-enzyme cascade reactions, critical for biocatalysis and pharmaceutical synthesis.

Optimizing Multi-Enzyme Cascades: A Comprehensive Design of Experiments (DoE) Guide for Biomedical Researchers

Abstract

This article provides a complete roadmap for applying Design of Experiments (DoE) to optimize complex multi-enzyme cascade reactions, critical for biocatalysis and pharmaceutical synthesis. We cover foundational principles, strategic experimental design for multi-factor systems, troubleshooting common pitfalls, and robust methods for validation. Tailored for researchers and drug development professionals, this guide bridges statistical methodology with practical application to accelerate the development of efficient, scalable enzymatic processes.

The Why and What: Understanding DoE Fundamentals for Complex Enzyme Systems

Application Notes: The Case for DoE in Cascade Optimization

Multi-enzyme cascades mimic natural metabolic pathways for sustainable synthesis of complex molecules, including pharmaceutical intermediates. However, their development is hampered by multidimensional optimization challenges. Traditional One-Variable-at-a-Time (OVAT) approaches are inefficient and fail to capture critical factor interactions, leading to suboptimal performance and missed synergies.

Table 1: Key Optimization Variables & Their Interactions in a Model Cascade (e.g., Cell-Free NADPH Regeneration)

| Variable Category | Specific Factor | Typical Range Studied | Observed Interaction with Enzyme Ratio (Example) |

|---|---|---|---|

| Physical-Chemical | pH | 6.5 - 8.5 | Strong interaction with cofactor stability and enzyme kinetics. |

| Chemical | Mg²⁺ Concentration | 1 - 10 mM | Interacts with ATP concentration and kinase activity. |

| Enzyme-Related | Enzyme A : Enzyme B Ratio | 1:5 to 5:1 | Central driver of flux; interacts with substrate loading. |

| Process | Temperature | 25 - 37 °C | Interacts with pH and enzyme half-life. |

| Substrate/Cofactor | Initial ATP Load | 0.1 - 2.0 mM | Interacts with Mg²⁺ and impacts feedback inhibition. |

Table 2: OVAT vs. DoE Approach Outcomes for a 3-Enzyme Cascade

| Optimization Metric | OVAT Method Result | Structured DoE (Fractional Factorial) Result | % Improvement |

|---|---|---|---|

| Final Product Titer (mM) | 4.8 ± 0.3 | 8.1 ± 0.2 | +68.8% |

| Total Reaction Time (hrs) | 6.0 | 3.5 | -41.7% |

| Cofactor Turnover Number (TON) | 120 | 450 | +275% |

| Number of Experiments Required | 45 | 16 | -64.4% |

Protocol: Design of Experiments (DoE) for Initial Cascade Screening

Objective: To efficiently screen the main effects and two-factor interactions of four critical variables (pH, [Mg²⁺], Enzyme Ratio, Temperature) on product yield and reaction rate using a fractional factorial design.

Materials & Reagent Solutions:

- Research Reagent Solutions:

- Immobilized Enzyme Cocktail: Lyophilized or co-immobilized enzymes (e.g., kinase, dehydrogenase, synthase). Function: Central biocatalysts; immobilization can enhance stability and reusability.

- Regenerated Cofactor System (e.g., NADP⁺/NADPH): Includes sacrificial substrate and regenerating enzyme (e.g., glucose dehydrogenase). Function: Maintains cofactor homeostasis cost-effectively.

- Broad-Range Buffer System (e.g., HEPES or Tris): 1.0 M stock, pH adjustable. Function: Maintains pH across the experimental design space.

- High-Purity Substrate/Precursor: >98% purity in DMSO or buffer stock. Function: Ensures reproducible initial reaction conditions.

- Stopping/Quenching Agent: e.g., 2M HCl or acetonitrile with internal standard. Function: Precisely halts reaction for analysis.

Procedure:

- Experimental Design: Generate a 2⁴⁻¹ fractional factorial design (Resolution IV) using statistical software (e.g., JMP, Minitab, R). This creates 8 unique experimental runs, plus 3 center point replicates (total n=11).

- Factor Level Preparation:

- Prepare master reaction mix containing all common components (substrate, cofactor, regenerating system).

- Aliquot master mix into 11 reaction vials.

- Independently adjust each vial to specified levels of pH (using buffer stock), [Mg²⁺] (from a MgCl₂ stock), and Temperature (using a thermocycler or water baths).

- Reaction Initiation: Start reactions by adding the predetermined Enzyme Ratio (varied by volume of separate enzyme stock solutions) to each vial. Vortex briefly.

- Kinetic Monitoring: Immediately transfer an aliquot to a pre-equilibrated microplate. Monitor initial reaction rate (V₀) spectrophotometrically (e.g., NADPH absorbance at 340 nm) for 5 minutes.

- Endpoint Analysis: Quench remaining main reaction at t=60 minutes with stopping agent. Analyze product formation via HPLC or LC-MS using a validated method.

- Data Analysis: Input Yield (mM) and V₀ (mM/min) as responses into the DoE software. Perform ANOVA to identify significant main effects and interactions. Generate response surface and contour plots.

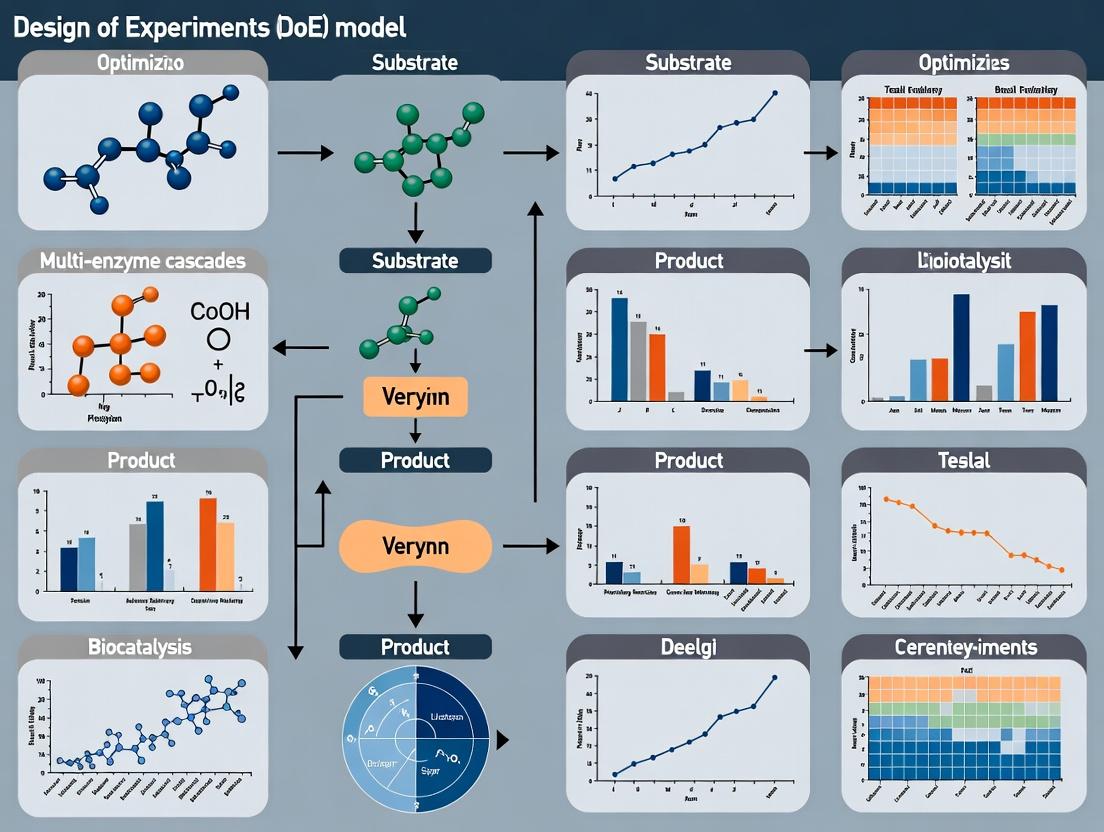

Visualizations

(Title: OVAT vs DoE in Cascade Development)

(Title: Structured DoE Workflow for Cascade Optimization)

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Multi-Enzyme Cascade Optimization |

|---|---|

| Stabilized Cofactor Pools | Engineered cofactors (e.g., polyethylene glycol (PEG)-NAD⁺) with enhanced stability and membrane permeability for in vitro or whole-cell systems. |

| Broad-Specificity Assay Kits | Coupled enzymatic/colorimetric assays for rapid, high-throughput quantification of common functional groups (amines, aldehydes, phosphates). |

| Cross-Linking Enzyme Aggregates (CLEAs) | Immobilized enzyme preparations offering enhanced stability, easy recovery, and tunable enzyme ratios in a single carrier-free particle. |

| Oxygen-Scavenging/Control Systems | Enzyme-based (e.g., glucose oxidase/catalase) or chemical systems to precisely control dissolved O₂, critical for oxidoreductases. |

| Time-Sampled Quenching Devices | Automated microfluidic or handheld devices for precise, reproducible quenching of reactions at millisecond intervals for accurate kinetics. |

Application Notes: DoE for Multi-Enzyme Cascade Optimization

Design of Experiments (DoE) is a systematic, statistical approach for planning and conducting experiments to efficiently optimize processes. In multi-enzyme cascade research—a cornerstone of modern biocatalysis for drug intermediate synthesis—DoE is indispensable for navigating complex variable landscapes. Unlike one-factor-at-a-time (OFAT) approaches, DoE identifies not just main effects but also critical interaction effects between factors such as pH, temperature, cofactor concentrations, and enzyme ratios, which are pivotal for cascade efficiency and yield.

Key Principles in a Biocatalytic Context

- Factors: The independent variables deliberately varied. These are categorized as:

- Controllable: (e.g., Temperature (°C), pH, Enzyme A:B Ratio, Substrate Influx Rate, Cofactor [Mg²⁺]).

- Uncontrollable (Noise): (e.g., batch-to-batch enzyme activity variation, minor impurity profiles in substrates).

- Responses: The measured outcomes or dependent variables. For an enzyme cascade, primary responses include:

- Final Product Yield (%)

- Total Turnover Number (TTN)

- Reaction Rate (mM/min)

- By-product Formation (%)

- Process Mass Intensity (PMI)

- Interactions: Occur when the effect of one factor depends on the level of another. For example, the optimal temperature for maximal yield may shift depending on the pH of the buffer. DoE models these interactions (e.g., Temp*pH), which are often the key to robust process understanding.

Table 1: Typical Factor Ranges and Effects on Cascade Yield (Response)

| Factor | Low Level (-1) | High Level (+1) | Main Effect on Yield (Typical) | Key Interaction (Example) |

|---|---|---|---|---|

| Temperature | 25°C | 37°C | Positive (to an optimum) | Temp * pH: High temp may be deleterious at low pH. |

| pH | 7.0 | 8.5 | Curvilinear | pH * [Cofactor]: Cofactor stability often pH-dependent. |

| [Enzyme A] | 0.5 mg/mL | 2.0 mg/mL | Positive, subject to saturation | [Enz A] * [Enz B]: Optimal ratio is critical for flux. |

| [Cofactor] | 1.0 mM | 5.0 mM | Positive, then plateau | [Cofactor] * Temp: May affect binding kinetics. |

Table 2: Example Full Factorial DoE (2^3 Design) for Screening

| Run | Temp | pH | [Cofactor] | Yield (%) |

|---|---|---|---|---|

| 1 | -1 (25°C) | -1 (7.0) | -1 (1 mM) | 45 |

| 2 | +1 (37°C) | -1 | -1 | 58 |

| 3 | -1 | +1 (8.5) | -1 | 62 |

| 4 | +1 | +1 | -1 | 71 |

| 5 | -1 | -1 | +1 (5 mM) | 52 |

| 6 | +1 | -1 | +1 | 65 |

| 7 | -1 | +1 | +1 | 75 |

| 8 | +1 | +1 | +1 | 82 |

Experimental Protocols

Protocol 1: Screening Experiments Using a 2-Level Full Factorial Design

Objective: Identify significant factors (Temperature, pH, Enzyme Ratio) influencing final product yield in a 3-enzyme cascade.

Materials: See "The Scientist's Toolkit" below.

Method:

- Experimental Design: Generate a 2³ full factorial design matrix (8 experiments + 3 center points for curvature check) using statistical software (e.g., JMP, Minitab, Design-Expert).

- Reaction Setup:

- Prepare a master mix of buffer (e.g., 50 mM Tris) and primary substrate.

- Aliquot the master mix into 24-well micro-reactor plates according to the design matrix.

- Adjust pH of each well to target levels (±0.05) using dilute HCl or NaOH.

- Place the plate on a thermostated microplate shaker set to the specified temperatures (±0.5°C).

- Initiation & Quenching:

- Start reactions by adding an enzyme cocktail (Enzymes A, B, C) at the specified ratios via a multichannel pipette.

- Allow reactions to proceed for a fixed time (e.g., 60 min).

- Quench reactions instantly by adding 50 µL of 1M HCl (or appropriate quenching agent) to each well.

- Analysis:

- Centrifuge plates (3000 x g, 5 min) to remove precipitates.

- Dilute supernatants appropriately with mobile phase.

- Analyze product concentration via calibrated UPLC-UV/MS.

- Data Analysis:

- Input yield data into the DoE software.

- Fit a first-order linear model with interaction terms:

Yield = β₀ + β₁(Temp) + β₂(pH) + β₃(Ratio) + β₁₂(Temp*pH) + β₁₃(Temp*Ratio) + β₂₃(pH*Ratio). - Use ANOVA (p<0.05) and Pareto charts to identify significant factors/interactions.

Protocol 2: Response Surface Methodology (RSM) for Optimization

Objective: Find the optimal levels of two critical factors (identified in Screening) to maximize yield.

Method:

- Design: Employ a Central Composite Design (CCD) around the suspected optimum (e.g., 5 levels for each of the two key factors, 13 runs total).

- Execution: Perform cascade reactions as in Protocol 1, strictly following the CCD matrix for the two factors while holding others constant.

- Modeling & Optimization:

- Fit a second-order quadratic model:

Yield = β₀ + β₁A + β₂B + β₁₁A² + β₂₂B² + β₁₂AB. - Generate contour (2D) and response surface (3D) plots from the model.

- Use the software's numerical optimizer to find factor levels that maximize predicted yield, potentially with constraints (e.g.,

[Cofactor] < 4 mM).

- Fit a second-order quadratic model:

Visualizations

DoE Workflow for Enzyme Cascade Optimization

Factors Influencing a 2-Step Enzyme Cascade

The Scientist's Toolkit

Table 3: Essential Research Reagent Solutions for DoE in Enzyme Cascades

| Reagent / Material | Function in DoE Context |

|---|---|

| Multi-Buffer Stock System (e.g., Tris, Phosphate, HEPES across pH range) | Enables rapid, precise pH adjustment across factorial design points without introducing confounding ionic strength variables. |

| Enzyme Master Stocks (Lyophilized) | Ensures consistent starting activity across all experimental runs; critical for distinguishing true factor effects from noise. |

| Quenching Solution Plates (Pre-dispensed acid/base/chelator) | Allows simultaneous, precise quenching of microplate reactions for accurate kinetic snapshots. |

| Internal Standard Mix for Analytics | Added post-quench to correct for analytical instrument variability (UPLC/MS), improving response data quality. |

| Thermostated Microplate Shaker/Incubator | Precisely controls temperature (a key factor) with mixing for uniform reaction conditions in high-throughput setups. |

| Statistical DoE Software (JMP, Design-Expert, Minitab) | Used to generate design matrices, randomize run order, and perform ANOVA & regression modeling of responses. |

Application Notes: DoE for Multi-Enzyme Cascade Optimization

Quantitative Efficiency Gains

A comparative analysis between One-Factor-At-a-Time (OFAT) and Definitive Screening Design (DSD) for a three-enzyme cascade (Cellulase, Xylanase, β-Glucosidase) reveals stark differences in resource utilization and information yield.

Table 1: Experimental Efficiency Comparison

| Metric | OFAT Approach | DSD (DoE) Approach | Advantage Ratio |

|---|---|---|---|

| Total Experiments | 81 (3^4 factors) | 17 runs | 4.8x more efficient |

| Time to Completion | 5 weeks | 7 days | 5x faster |

| Interaction Effects Discovered | 0 (by design) | 6 significant | ∞ |

| Predictive Model R² | Not possible | 0.92 | N/A |

| Material Consumed | 810 mL | 170 mL | 4.8x less |

Critical Interaction Discovery

In a recent study optimizing a cytochrome P450 cascade with a ferredoxin reductase partner, a full factorial DoE (2^3) uncovered a profound synergistic interaction between pH and cofactor concentration (NADPH). This interaction, invisible to OFAT, accounted for a 40% increase in total turnover number (TTN).

Table 2: Significant Interactions in a P450 Cascade

| Factor A | Factor B | Interaction p-value | Effect on TTN | Biological Implication |

|---|---|---|---|---|

| pH | [NADPH] | 0.003 | +40% | Protonation state affects cofactor binding affinity |

| [Enzyme A] | [Enzyme B] | 0.017 | +22% | Complex formation reduces substrate diffusion distance |

| Temperature | Mg²⁺ | 0.032 | +15% | Divalent cation stabilizes enzyme structure at higher T |

Predictive Power for Response Surface Mapping

A Central Composite Design (CCD) applied to a transaminase-amine dehydrogenase cascade generated a robust quadratic model. This model accurately predicted an optimal operating space, later validated, yielding a 3.1-fold improvement in product enantiomeric excess (e.e.) over the OFAT-derived baseline.

Table 3: Model Validation Results

| Predicted Optimal Point | Predicted e.e. | Actual e.e. (Validation Run) | Prediction Error |

|---|---|---|---|

| pH=7.8, T=32°C, [Sub]=45mM | 94.5% | 92.7% | 1.8% |

| OFAT "Optimum" (pH=7.5, T=37°C, [Sub]=30mM) | N/A (No model) | 30.1% | N/A |

Detailed Experimental Protocols

Protocol 1: Definitive Screening Design for Initial Cascade Characterization

Objective: Rapidly screen 5-7 critical factors (e.g., enzyme ratios, pH, temp, cofactors) for main effects and active two-factor interactions with minimal runs.

Materials: See "Scientist's Toolkit" below. Procedure:

- Design Generation: Use statistical software (JMP, Design-Expert, R

rsmpackage) to generate a DSD forkfactors (e.g., 6 factors in 13 runs). - Experimental Setup: Prepare master mixes for each enzyme component. In a 96-deep well plate, assemble reactions according to the randomized run order specified by the design matrix. Maintain a constant total reaction volume (e.g., 200 µL).

- Process Execution: Incubate plate in a thermocycler or thermal shaker with precise temperature control. Quench reactions at a predetermined timepoint with 20 µL of 2M HCl.

- Analysis: Quantify product via UPLC-MS or a calibrated fluorescent/colorimetric assay. Record response (e.g., yield, rate, TTN).

- Statistical Analysis:

- Fit a model containing all main effects and two-factor interactions.

- Use forward selection with a stringent alpha (e.g., 0.01) to identify significant effects.

- Generate a Pareto chart of effects and a prediction profiler.

Protocol 2: Response Surface Methodology (RSM) for Optimization

Objective: Model the nonlinear relationship between key factors identified in screening and find the optimum.

Procedure:

- Design Selection: For 2-4 critical factors, employ a Central Composite Design (CCD) or Box-Behnken Design (BBD). A CCD for 3 factors requires ~20 runs (8 factorial points, 6 axial points, 6 center points).

- Experimental Execution: Perform runs in fully randomized order to avoid confounding with temporal drift. Include center point replicates to estimate pure error.

- Model Fitting & Validation:

- Fit a second-order polynomial model:

Y = β₀ + ΣβᵢXᵢ + ΣβᵢᵢXᵢ² + ΣβᵢⱼXᵢXⱼ. - Perform ANOVA to assess model significance and lack-of-fit.

- Check diagnostics: Normal probability plot of residuals, residuals vs. predicted plot.

- Use the model's optimization function to find desired maximum(s) or minimum(s).

- Conduct 3-5 confirmation experiments at the predicted optimum.

- Fit a second-order polynomial model:

Visualizations

Title: OFAT vs DoE Workflow for 2 Factors

Title: Multi-Enzyme Cascade with Critical Factors

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Materials for DoE in Enzyme Cascades

| Item | Function & Relevance to DoE |

|---|---|

| Statistical Software (JMP/Design-Expert/R) | Generates efficient design matrices, analyzes complex data, fits models, and performs optimization. Crucial for implementing DoE. |

| Automated Liquid Handler (e.g., Beckman FX) | Enables precise, high-throughput assembly of dozens of unique reaction conditions specified by a design matrix with minimal error. |

| 96- or 384-Well Deep Well Plates | Miniaturized reaction vessels allowing parallel execution of many DoE runs, conserving precious enzyme and substrate. |

| Multi-Channel Pipette & Reagent Reservoirs | For rapid, parallel dispensing of common components (buffers, cofactors) across multiple DoE runs. |

| Controlled-Temperature Incubator/Shaker | Precisely controls a critical factor (temperature) across all experimental runs, reducing noise. |

| Rapid-Quench Solution (e.g., Acid/Base) | Stops all enzymatic activity at exact timepoints, ensuring accurate kinetic measurements for model responses. |

| UPLC-MS/HPLC System with Autosampler | Provides quantitative, multi-analyte data (substrate, intermediates, product) for comprehensive response measurement from small-volume DoE runs. |

| Stable, Lyophilized Enzyme Preps | Ensures consistent activity across the entire DoE study, a prerequisite for reliable model building. |

| Designated DoE Lab Notebook Template | Pre-formatted sheets to record run order, factor levels, and responses, preventing transcription errors from design matrix to lab record. |

Application Notes for DoE in Multi-Enzyme Cascade Optimization

Within a Design of Experiments (DoE) framework for multi-enzyme cascade research, rigorous preliminary planning is critical. These initial steps define the experimental space and ensure data quality and relevance.

Defining Objectives: The primary objective is to systematically identify and model the effects of key process parameters (e.g., pH, temperature, enzyme ratios, substrate concentration, cofactor levels) on the cascade's performance. This moves beyond one-factor-at-a-time (OFAT) approaches to capture interactions and nonlinear effects, aiming to establish a robust, predictive model for optimization.

Selecting Critical Quality Attributes (CQAs): CQAs are measurable indicators of cascade performance and product quality. Selection is based on risk to process efficacy and final product specifications. For a therapeutic enzyme cascade producing an active pharmaceutical ingredient (API), CQAs are hierarchically linked to Quality Target Product Profile (QTPP) elements.

Scoping Factors: A risk assessment, often using prior knowledge and literature, is conducted to screen potential factors. High-risk factors likely to significantly impact CQAs are selected as independent variables for the DoE. Low-risk or fixed parameters are controlled at constant levels.

Table 1: Hierarchy of CQAs for a Model API-Producing Enzyme Cascade

| QTPP Element | Associated CQA | Target | Justification |

|---|---|---|---|

| Potency | Final Product Titer (mM) | > 50 mM | Directly impacts dosage and economic viability. |

| Purity | % API by HPLC | > 98.5% | Critical for patient safety and regulatory approval. |

| Process Efficiency | Total Yield (%) | > 85% | Key metric for resource utilization and cost. |

| Process Robustness | Space-Time Yield (g/L/h) | Maximize | Indicates productivity and scalability potential. |

| Impurity Profile | % Key Side-Product | < 1.0% | Must be controlled within toxicology limits. |

Table 2: Scoped Experimental Factors and Ranges for Screening DoE

| Factor Name | Type | Low Level (-1) | High Level (+1) | Rationale for Inclusion |

|---|---|---|---|---|

| pH | Continuous | 6.5 | 8.0 | Affects activity/stability of all enzymes. |

| Temperature (°C) | Continuous | 25 | 37 | Trade-off between reaction rate and enzyme denaturation. |

| Enzyme 1:Enzyme 2 Ratio | Continuous | 1:2 | 2:1 | Stoichiometry and kinetics dictate optimal balance. |

| Initial Substrate [S] (mM) | Continuous | 50 | 200 | May influence rate and potential inhibition. |

| Cofactor Concentration (mM) | Continuous | 0.5 | 2.0 | Essential for oxidoreductase classes; cost driver. |

| Buffer Ionic Strength (mM) | Categorical | 50 (Low) | 150 (High) | Can modulate enzyme activity and protein-protein interactions. |

Experimental Protocols

Protocol 1: Defining CQAs via High-Throughput Microscale Screening

Objective: To rapidly quantify primary CQAs (Titer, Yield) from multiple cascade reactions run in parallel under varying conditions. Materials: See "Scientist's Toolkit" below. Method:

- Experimental Design Setup: Use DoE software to generate a screening design (e.g., fractional factorial or Plackett-Burman) for the factors in Table 2. Randomize the run order.

- Reaction Assembly: In a 96-deep well plate, prepare master mixes of buffer components. Using a liquid handler, dispense variable volumes to achieve the designed factor levels. Add enzyme stocks last to initiate reactions. Seal plate to prevent evaporation.

- Incubation: Place plate in a thermostatted shaker (compatible with microplates) set to the designed temperature with orbital shaking at 500 rpm for the fixed reaction duration (e.g., 2 hours).

- Quenching & Dilution: After incubation, automatically quench reactions by adding 100 µL of 1 M HCl (or suitable quenching agent) to each well. Perform appropriate dilutions in a new 96-well PCR plate using a diluent compatible with downstream analysis.

- Analytical Sampling: Inject samples from the dilution plate via an autosampler into an UHPLC system equipped with a UV/VIS or CAD detector. Use a validated method to separate and quantify the API and key side-products.

- Data Processing: Integrate chromatographic peaks. Calculate titer (mM) and yield (%) based on external standard curves. Compile data matrix for DoE analysis.

Protocol 2: Scoping Factors via Risk Assessment and Prior Knowledge Review

Objective: To systematically identify and prioritize potential factors for inclusion in the initial DoE. Method:

- Brainstorming Session: Assemble a multidisciplinary team (biocatalysis, process engineering, analytics) to list all conceivable factors that could influence the cascade. Use tools like cause-and-effect (Ishikawa) diagrams.

- Literature Mining: Perform a structured search (e.g., in PubMed, Scopus) for similar multi-enzyme systems or individual enzyme homologs. Extract reported optimal ranges and sensitive parameters.

- Risk Ranking and Filtering: Create a risk assessment matrix. Score each factor on a scale (e.g., 1-5) for its Potential Impact on CQAs (based on literature/mechanism) and the Level of Uncertainty (lack of data). Multiply scores to obtain a risk priority number (RPN).

- Factor Categorization: Factors with high RPN are designated as Experimental Variables for DoE. Factors with moderate RPN but that are expensive or difficult to vary (e.g., expression host) may be set as Controlled Constant factors. Factors with low RPN are Noise Factors to be monitored.

- Range Justification: For each experimental variable, define the minimum and maximum level based on literature extremes, enzyme stability data, or solubility limits, ensuring the range is wide enough to detect an effect but not so wide as to cause complete failure.

Mandatory Visualizations

(Diagram 1: Preliminary Steps in the DoE Workflow)

(Diagram 2: Relationship Between QTPP, CQAs, and Parameters)

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Preliminary DoE Studies on Enzyme Cascades

| Item | Function/Application | Example Vendor/Product |

|---|---|---|

| Multi-Enzyme System (Lyophilized) | The biocatalysts of interest, often recombinantly expressed and purified. Required for assembling the cascade. | Sigma-Aldrich (various), Codexis (engineered enzymes) |

| High-Purity Substrates & Cofactors | Reaction starting materials and essential co-substrates (e.g., NAD(P)H, ATP, SAM). Purity critical for reproducible kinetics. | Carbosynth, Toronto Research Chemicals |

| Tris or Phosphate Buffer Salts | For preparing buffers at precise pH and ionic strength levels, a key controlled or experimental factor. | Thermo Fisher Scientific |

| 96-Deep Well Microplates (1-2 mL) | High-throughput reaction vessel for running many DoE conditions in parallel with small reagent volumes. | Azenta, Corning |

| Automated Liquid Handling System | Enables precise, reproducible dispensing of enzymes, substrates, and buffers for DoE assembly. | Hamilton Company, Beckman Coulter (Biomek) |

| Microplate Thermo-Shaker | Provides temperature control and agitation for reactions in microplates, a key experimental factor. | Eppendorf (ThermoMixer C) |

| UHPLC System with Autosampler | For rapid, quantitative analysis of reaction outcomes (titer, purity, yield) across many samples. | Waters (H-Class), Agilent (1290 Infinity II) |

| DoE Software | For designing statistically sound experiments and analyzing multivariate response data (e.g., JMP, Design-Expert, MODDE). | JMP (SAS), Minitab |

Within the thesis on Design of Experiments (DoE) for optimizing multi-enzyme cascades, selecting the appropriate experimental design is paramount. Enzyme cascades involve complex interactions between pH, temperature, substrate concentrations, cofactors, and enzyme ratios. This application note contrasts two critical, sequential DoE phases: initial factor screening using designs like Plackett-Burman (PBD) and subsequent optimization using Response Surface Methodology (RSM). Screening identifies the "vital few" influential factors from many, while RSM models curvature and interactions to find optimal conditions.

Theoretical Framework & Comparison

Core Objectives and Applications

Screening designs are used early in cascade development to efficiently eliminate non-significant variables. Optimization designs are employed to precisely model the response surface and locate a maximum (e.g., yield), minimum (e.g., byproduct), or desired operating window.

Quantitative Design Comparison

Table 1: Comparison of Screening and Optimization DoE Designs

| Aspect | Screening Designs (e.g., Plackett-Burman) | Optimization Designs (e.g., Response Surface) |

|---|---|---|

| Primary Goal | Identify key influential factors from many | Model curvature & find optimal factor settings |

| Experimental Runs | Low (N = multiple of 4; e.g., 12, 20, 24) | Higher (e.g., 13-30 for Central Composite) |

| Factor Coverage | High (can screen up to N-1 factors) | Low (typically 2-5 key factors) |

| Model Fidelity | Main effects only (aliased with interactions) | Full quadratic model (interactions & curvature) |

| Resolution | Resolution III or IV | Resolution V or higher |

| Best For Phase | Early-stage factor prioritization | Late-stage process optimization |

Table 2: Example Run Counts for Common Designs

| Design Type | Specific Design | Factors | Runs | Notes |

|---|---|---|---|---|

| Screening | Plackett-Burman | 11 | 12 | Resolution III |

| Screening | Fractional Factorial (2^(5-2)) | 5 | 8 | Resolution III |

| Optimization | Central Composite (CCD) | 3 | 20 (8 cube, 6 star, 6 center) | Full quadratic model |

| Optimization | Box-Behnken | 3 | 15 | Spherical, no corner points |

Application Protocols

Protocol A: Screening with a Plackett-Burman Design for a 3-Enzyme Cascade

Objective: Identify which of 7 factors significantly affect the final product titer (mg/L) of a cascade. Factors & Levels (-1, +1):

- A: pH (6.5, 7.5)

- B: Temperature (°C) (25, 35)

- C: [Enzyme 1] (mg/mL) (0.1, 0.5)

- D: [Enzyme 2] (mg/mL) (0.1, 0.5)

- E: [Enzyme 3] (mg/mL) (0.05, 0.2)

- F: [Cofactor] (mM) (0.5, 2.0)

- G: Incubation time (min) (30, 90)

Procedure:

- Design Generation: Generate a 12-run Plackett-Burman design matrix (N=12). Randomize run order.

- Reaction Assembly: In 1.5 mL microcentrifuge tubes, prepare reaction mixtures according to the design matrix. Use a master mix for common buffer components.

- Cascade Execution: Initiate reactions by adding the rate-limiting enzyme. Incubate in a thermomixer at the specified temperature with shaking (500 rpm).

- Quenching & Analysis: Stop reactions at the specified time by adding 50 µL of 1M HCl. Clarify by centrifugation (13,000 x g, 5 min). Analyze product concentration via HPLC-UV.

- Data Analysis: Perform linear regression/ANOVA. Rank factors by Pareto chart of standardized main effects. Select factors with p-value < 0.05 (or using half-normal plot) for optimization.

Protocol B: Optimization with a Central Composite Design (CCD)

Objective: Optimize the 3 most significant factors (e.g., pH, [Enzyme 1], [Cofactor]) from Protocol A to maximize product titer. Design: A face-centered CCD with 3 factors (α=1), comprising 8 factorial points, 6 axial points, and 6 center points (total 20 runs). Center points assess pure error and curvature.

Procedure:

- Design Setup: Define low, middle, and high levels for each factor. The axial points are set at ±α (here, ±1) from the center.

- Experimental Execution: Perform cascades as in Protocol A, following the randomized CCD run order. Include analytical replicates.

- Model Fitting: Fit a second-order polynomial model:

Y = β₀ + ΣβᵢXᵢ + ΣβᵢᵢXᵢ² + ΣβᵢⱼXᵢXⱼ. Use multiple regression. - Analysis & Validation: Check model adequacy (R², adj-R², pred-R², lack-of-fit test). Generate 3D response surface and contour plots. Locate the stationary point (maximum). Perform confirmatory runs at predicted optimum.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Reagents for DoE in Enzyme Cascades

| Reagent/Material | Function & Importance in DoE |

|---|---|

| Multifactor Thermonixer | Precise, simultaneous control of temperature and shaking for parallel miniaturized reactions, enabling execution of randomized design runs. |

| LC-MS/HPLC System | Provides accurate, quantitative analysis of cascade substrates, intermediates, and products—the critical response data for DoE models. |

| Statistical Software (JMP, Design-Expert, R) | Required for generating design matrices, randomizing runs, performing ANOVA, regression, and visualizing response surfaces. |

| 96-Well Deep Well Plates | Enable high-throughput assembly of reaction mixtures for screening designs, compatible with liquid handling robots. |

| Enzyme Cocktail Master Mixes | Ensure consistency when dispensing common components across many experimental runs, reducing preparation error. |

| Quenching Solution | Rapidly and uniformly stops enzymatic reactions at precise times, critical for accurate time-point data. |

| Internal Standards (isotope-labeled) | Used in LC-MS analysis to correct for sample preparation and instrument variability, improving data quality for modeling. |

Visualized Workflows

Diagram 1: Sequential DoE workflow for enzyme cascades (max 760px width).

Diagram 2: Structure of a Plackett-Burman screening design matrix (max 760px width).

Diagram 3: Central Composite Design point structure for optimization (max 760px width).

Strategic Design and Execution: Building Your DoE Plan for Cascade Optimization

Within the broader thesis on "Design of Experiments (DoE) for Optimizing Multi-Enzyme Cascades," this framework provides a structured protocol to transition from a theoretical hypothesis to a statistically robust experimental array. Efficient optimization of enzyme cascades—critical for biocatalysis in pharmaceutical synthesis—requires a systematic approach to navigate complex parameter spaces (e.g., pH, temperature, enzyme ratios, cofactor concentrations).

The Step-by-Step Framework

Phase 1: Hypothesis Formulation

- Objective: Define a clear, testable hypothesis linking process parameters to cascade performance metrics.

- Protocol:

- Identify Response Variables (Y): Select quantifiable outputs (e.g., % yield, final product titer, total turnover number (TTN)).

- Define Critical Process Parameters (X): List all potential influencing factors via literature review and preliminary data.

- Formulate Hypothesis: State an expected cause-effect relationship. Example: "Simultaneous adjustment of pH (X₁) and molar ratio of Enzyme A to B (X₂) will significantly impact the product yield (Y₁) of the cascade reaction, with an anticipated interaction effect."

Phase 2: Factor Screening

- Objective: Distinguish vital few factors from the trivial many.

- Protocol: Employ a Plackett-Burman or Fractional Factorial design.

- Set each factor at a "High" (+1) and "Low" (-1) level.

- Execute the minimal experimental array per the design matrix.

- Analyze data using ANOVA to identify factors with statistically significant (p < 0.05) effects on the response.

Phase 3: Experimental Array Design (DoE)

- Objective: Create an optimized set of experiments to model system behavior.

- Protocol: For 2-5 critical factors, use a Response Surface Methodology (RSM) design.

- Select Design Type: Central Composite Design (CCD) or Box-Behnken Design.

- Define Levels: Include axial/center points (e.g., 5 levels per factor in CCD).

- Generate Array: Use statistical software (JMP, Minitab, Design-Expert) to create a randomized run order, minimizing batch effects.

Phase 4: Execution & Analysis

- Objective: Run experiments and fit a predictive model.

- Protocol:

- Execute reactions per the array under controlled conditions.

- Quantify responses via HPLC or UV/Vis spectrometry.

- Fit data to a second-order polynomial model:

Y = β₀ + ΣβᵢXᵢ + ΣβᵢᵢXᵢ² + ΣβᵢⱼXᵢXⱼ. - Validate model via lack-of-fit test and R² (adjusted & predicted).

Data Presentation

Table 1: Example 2-Factor Central Composite Design (CCD) Array for Enzyme Cascade Optimization

| Run Order | Coded Value: pH (X₁) | Coded Value: Enzyme Ratio (X₂) | Actual pH | Actual Ratio (A:B) | Observed Yield % (Y) |

|---|---|---|---|---|---|

| 1 | -1 | -1 | 6.0 | 1:1 | 45.2 |

| 2 | +1 | -1 | 8.0 | 1:1 | 62.1 |

| 3 | -1 | +1 | 6.0 | 1:3 | 38.7 |

| 4 | +1 | +1 | 8.0 | 1:3 | 81.5 |

| 5 | -α | 0 | 5.5 | 1:2 | 33.0 |

| 6 | +α | 0 | 8.5 | 1:2 | 70.4 |

| 7 | 0 | -α | 7.0 | 1:0.5 | 58.9 |

| 8 | 0 | +α | 7.0 | 1:3.5 | 65.2 |

| 9-13 | 0 | 0 | 7.0 | 1:2 | 71.3, 72.8, 70.5, 73.1, 71.9 |

Experimental Protocols

Protocol: High-Throughput Screening for Initial Factor Assessment

- Purpose: Rapid assessment of factor levels for screening design.

- Materials: 96-well deep-well plate, multichannel pipette, thermoshaker, microplate reader.

- Method:

- Prepare master mixes of buffer components and substrates.

- Vary one factor per column/row as per the design matrix.

- Initiate reactions by adding enzyme mix. Final reaction volume: 500 µL.

- Incubate at 30°C, 500 rpm for 2 hours.

- Quench with 100 µL of 1M HCl. Centrifuge at 3000 x g for 5 min.

- Transfer 150 µL supernatant to a UV-star plate. Measure product absorbance at 340 nm.

- Calculate yield against a standard curve.

Protocol: Analytical HPLC for Response Quantification (Definitive Runs)

- Purpose: Accurate quantification of cascade product yield for RSM analysis.

- Materials: HPLC system with C18 column, UV detector, 0.22 µm syringe filters.

- Method:

- Quench 100 µL reaction aliquot with 300 µL acetonitrile. Vortex for 1 min.

- Centrifuge at 14,000 x g for 10 min. Filter supernatant.

- Inject 10 µL onto column equilibrated with 95% Solvent A (0.1% TFA in H₂O), 5% Solvent B (0.1% TFA in Acetonitrile).

- Run gradient: 5% B to 60% B over 15 min. Flow rate: 1.0 mL/min.

- Detect at 254 nm. Integrate peaks and calculate yield using external standard calibration curve (1-100 mg/L).

Mandatory Visualization

Title: DoE Framework for Enzyme Cascade Optimization

Title: Multi-Enzyme Cascade for Drug Synthesis

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Multi-Enzyme Cascade DoE Studies

| Item | Function / Role in DoE |

|---|---|

| Immobilized Enzyme Systems (e.g., on magnetic beads) | Enables easy ratio adjustment (a key factor) and reuse; improves stability across pH/temperature gradients. |

| Cofactor Recycling Systems (e.g., GDH/Glucose for NADPH) | Decouples cofactor cost from optimization, allowing focus on enzyme kinetic parameters. |

| High-Throughput Analytics Kit (e.g., coupled spectrophotometric assay) | Allows rapid data collection for the many runs required in a screening or RSM array. |

| Statistical Software (JMP, Design-Expert, Minitab) | Generates optimal experimental arrays, randomizes run order, and performs ANOVA/RSM analysis. |

| Modular Buffer System (e.g., Tris, Phosphate, HEPES stocks) | Facilitates precise and reproducible pH adjustment across a wide range (a common continuous factor). |

| In-Line Process Analyzers (pH, dissolved O₂ probes) | Provides real-time monitoring of critical process parameters (CPPs) during reaction progress. |

Within the thesis "Design of Experiments (DoE) for Optimizing Multi-Enzyme Cascades," factor selection is the critical first step. A well-designed multi-enzyme cascade for biosynthesis or drug intermediate production requires systematic optimization of interdependent biochemical and physical parameters. This Application Note details the pivotal factors—enzyme ratios, pH, temperature, cofactors, and substrate concentrations—providing protocols for their initial characterization and integration into a subsequent DoE framework to efficiently identify optimal reaction conditions.

Table 1: Typical Operational Ranges for Key Factors in Multi-Enzyme Cascades

| Factor | Typical Investigative Range | Common Optimal Zone (Varies by system) | Key Interaction Considerations |

|---|---|---|---|

| pH | 6.0 - 9.0 | 7.0 - 8.0 (for many cytosolic enzymes) | Strongly affects enzyme stability, activity, and cofactor affinity. Interacts with temperature. |

| Temperature | 20°C - 50°C | 30°C - 37°C (for mesophilic enzymes) | Affects reaction rate, enzyme denaturation, and byproduct formation. Interacts with pH. |

| Cofactor Conc. (e.g., NAD+) | 0.1 - 5.0 mM | 0.5 - 2.0 mM | Must be balanced with substrate flux to avoid depletion or excessive cost. Often recycled. |

| Substrate Conc. ([S]) | 0.1x - 10x Km | 1x - 5x Km (to avoid inhibition) | High [S] can cause inhibition; must match enzyme capacity. Critical for cascade flux. |

| Enzyme Ratio (E1:E2:En) | 1:1:1 to 1:10:10 (molar or activity-based) | Highly system-dependent | Determines flux balance, minimizes intermediate accumulation, and maximizes yield. |

Table 2: Example Initial Screening Data for a Two-Enzyme Cascade (Glucose → Fructose → Sorbitol)

| Condition | pH | Temp (°C) | [ATP] (mM) | [NADH] (mM) | Enzyme 1:2 Ratio | Observed Final Product Yield (%) |

|---|---|---|---|---|---|---|

| Baseline | 7.5 | 30 | 1.0 | 0.5 | 1:1 | 42 |

| High pH | 8.5 | 30 | 1.0 | 0.5 | 1:1 | 58 |

| High Temp | 7.5 | 40 | 1.0 | 0.5 | 1:1 | 35 |

| High Cofactor | 7.5 | 30 | 2.0 | 1.0 | 1:1 | 65 |

| High E2 | 7.5 | 30 | 1.0 | 0.5 | 1:2 | 78 |

Detailed Experimental Protocols

Protocol 1: Initial Factor Screening Using Univariate Analysis

Objective: To determine the approximate optimal range for each factor individually prior to DoE. Materials: See "The Scientist's Toolkit" below. Procedure:

- Establish Baseline: Run the cascade reaction at pH 7.5, 30°C, with mid-range cofactor and substrate concentrations, and a 1:1 enzyme activity ratio.

- Vary pH:

- Prepare separate reaction buffers (e.g., HEPES for pH 6.5-8.0, Tris for pH 7.5-9.0) adjusted to target pH values (6.0, 6.5, 7.0, 7.5, 8.0, 8.5).

- Initiate reactions with all other factors at baseline.

- Quench at fixed time points (e.g., 5, 10, 30 min).

- Vary Temperature:

- Using optimal pH from step 2, run reactions in thermostatted blocks or cyclers at 20, 25, 30, 35, 40, 45°C.

- Vary Cofactor Concentration:

- For each essential cofactor (e.g., NADH, ATP, Mg2+), prepare a dilution series (e.g., 0.1, 0.5, 1.0, 2.0, 5.0 mM).

- Run reactions at optimal pH and temperature.

- Vary Enzyme Ratio:

- Hold total protein constant or vary total activity. Prepare mixtures where the molar or activity ratio of E1:E2:En spans from 1:0.5:0.5 to 1:2:2.

- Run reactions under conditions optimized from steps 2-4.

- Analysis: Quantify final product yield and initial reaction velocity for each condition. Plot response vs. factor level to identify promising ranges for DoE.

Protocol 2: Coupled Activity Assay for Determining Functional Enzyme Ratios

Objective: To empirically determine the ratio that minimizes intermediate accumulation. Procedure:

- Setup: In a spectrophotometer or HPLC vial, combine buffer, cofactors, and substrates for the first enzyme.

- Initiate Cascade: Add a fixed amount of the first enzyme (E1). Monitor the appearance of the first intermediate (I1) spectroscopically or by rapid sampling for HPLC.

- Titrate Second Enzyme (E2): Repeat the reaction, but now include varying amounts of E2 (e.g., 0.1x, 0.5x, 1x, 2x relative to E1 activity).

- Monitor: Track both I1 accumulation and final product (P) formation. The optimal ratio is where I1 concentration remains low and steady-state, and P formation rate is maximal.

- Extend: For >2 enzymes, iterate this process downstream.

Visualization Diagrams

Title: DoE Optimization Workflow for Enzyme Cascades

Title: Key Factor Interactions in a Cascade Reaction

The Scientist's Toolkit: Research Reagent Solutions

| Item / Reagent | Function & Application | Key Consideration |

|---|---|---|

| HEPES Buffer | Effective buffering range pH 6.8-8.2. Used for initial pH screening of enzymes. | Minimal metal ion binding, ideal for cofactor-dependent enzymes. |

| Tris-HCl Buffer | Buffering range pH 7.0-9.0. Common for alkaline pH optima studies. | Temperature-sensitive pKa (~0.03/°C); requires precise temp control. |

| NAD+/NADH (or NADP+/NADPH) | Essential redox cofactors for dehydrogenases. Used to vary cofactor concentration and monitor reactions at 340 nm. | Prepare fresh solutions; check stability at working pH. Use recycling systems for cost-effectiveness. |

| Mg-ATP | Energy co-substrate for kinases and ATP-dependent enzymes. Varying [Mg2+] and [ATP] is critical. | Maintain Mg2+ in excess of ATP to ensure free Mg2+ for activation. |

| Immobilized Enzyme Kits | For facile adjustment of enzyme ratios via measured activity units (U). Simplifies recycling and ratio testing. | Ensure compatibility of immobilization matrix with all cascade components. |

| Stopped-Flow Apparatus | For rapid kinetic measurement of initial rates under different factor conditions (pH, temp). | Essential for capturing fast kinetics before product inhibition sets in. |

| LC-MS/HPLC System | For quantifying substrate, intermediate, and product concentrations to calculate yields and identify bottlenecks. | Enables monitoring of all chemical species simultaneously. |

| DoE Software (e.g., JMP, Modde, R) | For designing efficient experimental matrices (e.g., Central Composite Design) and modeling responses. | Critical for moving from univariate screening to multivariate optimization. |

Within the broader thesis on Design of Experiments (DoE) for optimizing multi-enzyme cascade reactions, selecting an appropriate initial screening design is paramount. Early-stage research often involves numerous factors—such as pH, temperature, enzyme ratios, cofactor concentrations, and substrate loadings—with potentially complex interactions. This Application Note compares two powerful design strategies for factor screening: Fractional Factorial Designs (FFD) and D-Optimal Designs. The objective is to efficiently identify the most influential factors affecting cascade yield and selectivity while minimizing experimental runs, conserving precious enzymes and substrates.

Quantitative Comparison of Screening Designs

Table 1: Core Characteristics of Fractional Factorial vs. D-Optimal Designs for Screening

| Feature | Fractional Factorial Design (FFD) | D-Optimal Design (for Screening) | ||

|---|---|---|---|---|

| Primary Goal | Identify main effects and low-order interactions with minimal runs. | Identify key effects from a large set of candidate factors, especially when classical designs are impractical. | ||

| Design Structure | Based on orthogonal arrays; a fraction (e.g., 1/2, 1/4) of a full factorial. | Computer-generated; selects a subset of runs from a candidate set to maximize the | X'X | determinant. |

| Run Efficiency | Highly efficient for factors with 2 levels (e.g., 8 runs for 7 factors in a 2^(7-4) design). | Highly flexible; can model specific terms with near-minimal runs (e.g., 12-20 runs for 8-10 factors). | ||

| Factor Levels | Typically 2 levels per factor (High/Low). | Can accommodate 2 or more levels, and mixture factors. | ||

| Aliasing Structure | Clear, known aliasing of effects (e.g., main effects confounded with 2-way interactions). | Aliasing is minimized for specified model but must be checked; not as inherently clear as FFD. | ||

| Model Assumptions | Requires pre-specification of resolution (e.g., Resolution III, IV). | Requires pre-specification of the model form to be estimated (e.g., main effects only). | ||

| Best for Screening When... | The number of factors is moderate (5-15), and run economy is critical. Assumptions about effect sparsity hold. | The design space is constrained (e.g., combinations of factor levels are impossible), or factors are categorical with >2 levels. | ||

| Key Limitation | Cannot estimate the full model; relies on effect hierarchy and sparsity. | Design is optimal only for the pre-specified model; may not perform well if model is incorrect. |

Table 2: Example Run Comparison for an 8-Factor Screening Study

| Design Type | Specific Design | Number of Runs | Effects Estimated Unambiguously | Key Assumption/Alias |

|---|---|---|---|---|

| Fractional Factorial | 2^(8-4) Resolution IV | 16 | All 8 main effects free of two-factor interaction (2FI) aliasing. | 2FI's are aliased with each other. |

| Fractional Factorial | 2^(8-3) Resolution III | 8 | All 8 main effects. | Main effects are aliased with 2FI's. |

| D-Optimal | Main Effects Model | 12 | 8 main effects + 3-4 degrees of freedom for error/lack of fit. | Model is correctly specified as main effects only. |

| D-Optimal | Main Effects + select 2FI's | 20 | 8 main effects + specified 2FI's. | Correct pre-identification of critical interactions is needed. |

Experimental Protocols for Screening Multi-Enzyme Cascades

Protocol 3.1: Screening Factor Selection and Level Definition

Objective: To define critical factors and their experimental ranges for the initial screening of a multi-enzyme cascade.

- Assemble Expert Knowledge: Form a team of enzymologists and process chemists. Use prior knowledge, literature, and preliminary data to list all potential influential factors (e.g., E1:E2 ratio, pH, [Mg2+], [NADPH], temperature, substrate concentration, reaction time).

- Categorize Factors: Classify as continuous (e.g., temperature) or categorical (e.g., buffer type).

- Define Practical Ranges: Set "Low" and "High" levels for each factor based on enzyme stability, solubility, and practicality. Avoid ranges that lead to complete reaction failure.

- Select Screening Design: Based on the number of factors (k) and resource constraints, choose between FFD and D-Optimal.

- If k is large (>7) and run economy is paramount, choose a Resolution III or IV FFD.

- If the design space has constraints (e.g., high pH and low temperature cannot run together) or includes categorical factors with >2 levels, choose a D-Optimal design.

- Generate Design Matrix: Use statistical software (JMP, Design-Expert, Minitab, R) to create the randomized run order.

Protocol 3.2: Execution of a Fractional Factorial Screening Experiment

Objective: To conduct the cascade reactions according to a 2^(7-4) Resolution IV FFD. Materials: See "Research Reagent Solutions" below. Procedure:

- Preparation: Prepare stock solutions of all enzymes, cofactors, and substrates. Pre-equilbrate water baths or thermoshakers to the target temperatures specified in the design matrix.

- Reaction Assembly (96-well plate scale): a. To each well, first add buffer to achieve final specified pH and volume. b. Sequentially add cofactors (e.g., NADPH, ATP) and metal ions (e.g., MgCl2) as per the design levels. c. Add the substrate(s) at the specified concentrations. d. Initiate the reaction by adding the enzyme mixture at the specified ratios (E1:E2:E3). Mix gently by pipetting.

- Incubation: Seal the plate and incubate at the specified temperature for the defined reaction time.

- Quenching: At the end of the incubation, quench all reactions simultaneously by adding 50 µL of quenching solution (e.g., 10% trichloroacetic acid or 90% MeOH) to each well.

- Analysis: Centrifuge the plate (3000 x g, 10 min) to precipitate proteins. Analyze the supernatant for product concentration via HPLC-UV/MS or a coupled enzymatic assay. Record yield (µM) and selectivity (if applicable) as response variables.

- Replication: Include at least 2-3 center points (all factors at mid-level) randomly distributed throughout the experiment to estimate pure error and check for curvature.

Protocol 3.3: Analysis of Screening Data and Model Selection

Objective: To identify significant factors from the screening experiment.

- Data Preparation: Compile response data with the corresponding factor levels for each run.

- Model Fitting (for FFD): Perform a linear regression analysis, fitting a model with all main effects. For Resolution IV designs, consider adding 2FI terms in a stepwise manner if degrees of freedom allow.

- Half-Normal Probability Plot: Construct a half-normal plot of the estimated effects. Effects that deviate significantly from the straight line formed by the negligible effects are deemed active.

- ANOVA & Pareto Analysis: Perform Analysis of Variance (ANOVA) for the model containing the active effects. Generate a Pareto chart of the standardized effects to visualize their relative magnitude and significance (p-value < 0.05 or 0.1).

- Model Diagnostics: Check residual plots (vs. predicted, vs. run order) for randomness and constant variance.

- Decision Point: Based on the identified 3-5 critical factors, plan a subsequent optimization design (e.g., Response Surface Methodology) for deeper investigation.

Visualizations

Design Selection Decision Pathway

Screening Experiment Core Workflow

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for DoE Screening of Enzyme Cascades

| Item | Function/Benefit in Screening |

|---|---|

| Recombinant Enzymes (lyophilized) | Essential catalysts. High purity and activity are critical for reproducible results across many experimental runs. |

| Cofactor Regeneration Systems | (e.g., Glucose/GDH for NADPH). Maintains cofactor homeostasis, reduces cost, and prevents signal depletion in long cascades. |

| Multi-Channel Pipettes & 96-Well Plates | Enables high-throughput, parallel assembly of many reaction conditions as per the design matrix, improving speed and consistency. |

| Thermostatted Microplate Shaker | Provides precise temperature control with mixing for incubation of small-volume reactions in plates. |

| Rapid Quenching Solution | (e.g., Acid, Organic Solvent). Instantly stops enzymatic activity at precise time points, fixing the reaction state for analysis. |

| UPLC/HPLC with Autosampler | Provides quantitative analysis of substrate depletion and product formation for multiple samples with high sensitivity and resolution. |

| Statistical Software | (JMP, Design-Expert, R with 'DoE.base', 'skpr'). Critical for generating design matrices, randomizing runs, and analyzing complex response data. |

| pH Buffer Starter Kit | Pre-mixed buffers covering a wide pH range (e.g., 5.0-9.0) to accurately set this critical factor without introducing ionic composition variability. |

Within the broader thesis on Design of Experiments (DoE) for optimizing multi-enzyme cascades, this application note details the practical implementation of two advanced response surface methodology (RSM) designs: Central Composite Designs (CCD) and Box-Behnken Designs (BBD). For drug development scientists and researchers, these designs are critical for efficiently modeling quadratic response surfaces, identifying optimal conditions (e.g., for enzyme activity, yield, or purity), and understanding complex factor interactions with a minimal number of experimental runs.

Core Design Principles & Comparative Analysis

Central Composite Design (CCD)

CCD is constructed from a factorial or fractional factorial design (2^k) augmented with center points and axial (star) points. This allows estimation of curvature. The distance of the axial points from the center (α) determines whether the design is rotatable (α = (2^k)^(1/4)) or face-centered (α = 1).

Box-Behnken Design (BBD)

BBD is a spherical, rotatable design based on incomplete three-level factorial designs. It combines two-level factorial designs with incomplete block designs. Notably, it avoids experiments at the extreme vertices (corner points) of the factor space, which can be advantageous when such combinations are impractical or unsafe.

Table 1: Quantitative Comparison of CCD and BBD for 3-Factor Optimization

| Feature | Central Composite Design (CCD) | Box-Behnken Design (BBD) |

|---|---|---|

| Total Runs (3 factors) | 20 (Full: 8 cube + 6 axial + 6 center) | 15 (12 edge midpoints + 3 center) |

| Factor Levels | 5 (if α≠1) | 3 |

| Design Space | Cuboidal or Spherical (depending on α) | Spherical |

| Ability to estimate full quadratic model | Yes | Yes |

| Location of Points | Cube vertices, axial points, center | Midpoints of edges and center |

| Rotatability | Achievable with appropriate α | Spherical and rotatable |

| Practical Advantage | Can explore extreme conditions; flexible α. | Fewer runs; avoids extreme corners. |

Experimental Protocols for Multi-Enzyme Cascade Optimization

Protocol: Implementing a CCD for a 3-Enzyme Cascade Reaction

Objective: Optimize temperature (X1), pH (X2), and cofactor concentration (X3) to maximize product yield.

Materials & Reagents: See "Scientist's Toolkit" (Section 6).

Procedure:

- Define Ranges: Set low (-1) and high (+1) levels for each factor (e.g., Temp: 20°C, 40°C; pH: 6.5, 8.5; Cofactor: 0.5 mM, 2.5 mM).

- Choose α Value: For a face-centered CCD (α=1), the axial points will be at the factorial boundaries.

- Generate Design Matrix: The 20-run design includes:

- Factorial Portion (8 runs): All combinations of ±1 levels.

- Axial Portion (6 runs): Vary one factor to ±α while others are at 0 (center).

- Center Points (6 runs): All factors at midpoint (0). These assess pure error and model stability.

- Randomize & Execute: Randomize the run order to mitigate confounding effects.

- Assay Product Yield: For each run, conduct the cascade reaction under specified conditions and quantify product via HPLC or spectrophotometry.

- Model Fitting: Use statistical software (e.g., JMP, Minitab, R) to fit a second-order polynomial model:

Y = β0 + ΣβiXi + ΣβiiXi² + ΣβijXiXj. - Validation: Perform confirmation experiments at predicted optimum conditions.

Protocol: Implementing a BBD for a 2-Step Cascade Purification

Objective: Optimize precipitation time (A), salt concentration (B), and flow rate (C) for maximum protein recovery and purity.

Procedure:

- Define Ranges: Set low (-1), middle (0), and high (+1) levels for each factor.

- Generate Design Matrix: The BBD for 3 factors arranges 12 experiments at the midpoints of the edges of the factor cube, plus 3-5 center point replicates (typically 15 total runs).

- Randomize & Execute: Perform purification runs in random order.

- Dual Response Measurement: For each run, measure both Recovery (%) and Purity (AU).

- Model Fitting & Desirability Function: Fit separate quadratic models for each response. Use a desirability function to find factor settings that simultaneously maximize both recovery and purity.

- Validation: Run the predicted optimal setting in triplicate to confirm.

Visualization of DoE Workflows

Diagram 1: CCD Implementation Protocol Flow (99 chars)

Diagram 2: BBD Avoids Extreme Factor Combinations (100 chars)

Data Analysis & Interpretation Example

Table 2: Sample ANOVA for a CCD on Cascade Yield (Partial)

| Source | Sum of Sq. | df | Mean Square | F-value | p-value |

|---|---|---|---|---|---|

| Model | 2450.6 | 9 | 272.3 | 24.8 | < 0.001 |

| X1-Temp | 850.1 | 1 | 850.1 | 77.4 | < 0.001 |

| X2-pH | 320.5 | 1 | 320.5 | 29.2 | 0.0002 |

| X3-Cofactor | 205.8 | 1 | 205.8 | 18.7 | 0.001 |

| X1X2 | 64.0 | 1 | 64.0 | 5.8 | 0.032 |

| X1² | 420.3 | 1 | 420.3 | 38.3 | < 0.001 |

| Residual | 109.9 | 10 | 11.0 | ||

| Lack of Fit | 89.2 | 5 | 17.8 | 4.1 | 0.065 |

| Pure Error | 20.7 | 5 | 4.1 |

Interpretation: The significant model (p<0.001) and non-significant lack of fit (p=0.065) indicate a good fit. All linear terms, one interaction (X1X2), and one quadratic term (X1²) are significant drivers of yield.

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for Multi-Enzyme Cascade DoE Studies

| Item | Function in Optimization | Example/Note |

|---|---|---|

| Thermostable Enzyme Mix | Core biocatalyst; must withstand varied DoE conditions (temp, pH). | Commercial blend or recombinantly expressed enzymes. |

| Cofactor Regeneration System | Maintains stoichiometry for NAD(P)H/ATP-dependent steps. | Glucose dehydrogenase (GDH) with glucose for NADPH recycle. |

| Buffered Substrate Cocktail | Provides consistent starting material across all experimental runs. | Prepared in bulk, aliquoted, pH-adjusted to central point. |

| HPLC-MS System | Quantifies final product and potential intermediates with high accuracy. | Critical for measuring cascade yield and selectivity. |

| Microplate Spectrophotometer | Enables rapid, parallel kinetic assays of enzyme activity. | For preliminary screening or measuring secondary responses. |

| Statistical Software | Generates design matrices, randomizes runs, and fits RSM models. | JMP, Design-Expert, Minitab, or R (rsm package). |

| pH & Temperature Station | Precisely controls and monitors critical environmental factors. | Ensures fidelity to DoE factor level settings. |

This application note presents a case study within a broader thesis on applying systematic Design of Experiments (DoE) to optimize complex multi-enzyme cascade reactions. Efficient biocatalytic cascades are critical for synthesizing chiral pharmaceutical intermediates, but their optimization is challenging due to interacting factors. This protocol details a DoE strategy for a model 3-enzyme system converting a prochiral substrate to a high-value intermediate.

The 3-Enzyme Cascade System

The model system synthesizes a chiral lactone, a precursor to a statin-side chain, via a three-step cascade:

- Ketoreductase (KRED): Asymmetric reduction of a keto-ester to a hydroxy-ester.

- Lipase: Hydrolysis of the ethyl ester to a hydroxy-acid.

- Lactonase: Intramolecular cyclization to form the chiral lactone. Key challenges include balancing reaction kinetics, cofactor (NADPH) regeneration, and pH shifts.

DoE Strategy & Screening Design

A two-phase DoE was implemented: screening to identify critical factors, followed by optimization.

Screening Phase: A Resolution IV fractional factorial design (2^(7-3)) was used to efficiently screen seven potential factors without confounding main effects with two-factor interactions.

Table 1: Factors and Levels for Screening Design

| Factor | Code | Low Level (-1) | High Level (+1) | Unit |

|---|---|---|---|---|

| KRED Concentration | A | 0.5 | 2.0 | g/L |

| Lipase Concentration | B | 1.0 | 5.0 | g/L |

| Lactonase Concentration | C | 0.1 | 0.5 | g/L |

| pH | D | 6.5 | 7.5 | - |

| Temperature | E | 25 | 35 | °C |

| Cofactor (NADP+) Concentration | F | 0.05 | 0.20 | mM |

| Substrate Loading | G | 10 | 30 | g/L |

Primary Response: Overall Cascade Yield (%) at 24 hours. Secondary Response: Enantiomeric Excess (e.e., %) of the final lactone.

Detailed Experimental Protocol for Screening

Protocol 4.1: Biocascade Reaction Setup

Objective: Execute the 7-factor, 16-run screening design in randomized order.

Materials & Reagents:

- Purified KRED, Lipase, and Lactonase enzymes.

- Substrate: Ethyl 4-chloro-3-oxobutanoate.

- NADP+ sodium salt.

- Potassium phosphate buffer (100 mM, pH adjustable).

- Isopropanol (10% v/v, for cofactor regeneration).

- HPLC vials and mobile phase (acetonitrile/water with 0.1% TFA).

Procedure:

- Buffer Preparation: Prepare 500 mL of 100 mM potassium phosphate buffer at the two target pH levels (6.5 and 7.5) using HCl or KOH. Verify pH with a calibrated meter.

- Master Mixture (MM): For each run, calculate required volumes. In a 10 mL reaction vessel, combine:

- Buffer (to achieve final 5 mL volume).

- NADP+ stock solution (10 mM in buffer) to target concentration.

- Substrate from a 100 g/L stock in isopropanol.

- Isopropanol to a final fixed concentration of 10% v/v.

- Enzyme Addition: Pre-equilibrate the MM to the target temperature (25°C or 35°C) in a temperature-controlled incubator shaker. Add the three enzymes at the concentrations specified by the design matrix. Start timing.

- Reaction Execution: Incubate with shaking at 200 rpm for 24 hours. Sample (100 µL) at t=0 and t=24h.

- Quenching & Analysis: Transfer samples to HPLC vials containing 100 µL of acetonitrile to stop the reaction. Vortex, centrifuge (13,000 rpm, 5 min), and analyze supernatant via chiral HPLC (e.g., Chiralpak AD-H column, 25°C, 1.0 mL/min, 220 nm detection).

- Data Collection: Calculate yield based on substrate depletion and lactone formation against a calibrated standard. Determine e.e. from chromatogram peak areas of enantiomers.

Results Analysis & Path Forward

Analysis of Variance (ANOVA) on the screening data identified pH (D), Temperature (E), and Substrate Loading (G) as the most statistically significant factors (p < 0.01) affecting yield. KRED concentration (A) was significant for e.e. Lipase and Lactonase concentrations were less critical within tested ranges.

Table 2: Pareto Analysis of Standardized Effects (Yield Response)

| Factor | Code | Effect | p-value |

|---|---|---|---|

| pH | D | +15.2 | 0.001 |

| Temperature | E | -8.7 | 0.012 |

| Substrate Loading | G | -12.5 | 0.003 |

| KRED Conc. | A | +4.1 | 0.152 |

| D x E Interaction | DE | -6.3 | 0.045 |

This informed the optimization phase, where a central composite design (CCD) was applied to the three critical factors (pH, Temperature, Substrate Loading) with KRED concentration held at its high level to maintain e.e. >99%.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for 3-Enzyme Cascade Optimization

| Item | Function/Justification |

|---|---|

| Lyophilized KRED (Code: KR-110) | Highly active, NADPH-dependent ketoreductase with broad substrate scope and excellent stereoselectivity. |

| Immobilized Lipase B (from C. antarctica) | Robust, thermostable hydrolase; immobilization allows for potential recovery and reuse. |

| Recombinant Lactonase (His-tagged) | Facilitates purification and activity assessment; crucial for driving equilibrium toward lactone. |

| NADP+ Sodium Salt (High Purity) | Essential cofactor for KRED; its stability and cost necessitate efficient in-situ regeneration. |

| Isopropanol (ACS Grade) | Serves as a co-solvent for substrate and as the sacrificial donor for NADPH regeneration. |

| Chiral HPLC Column (e.g., Chiralpak AD-H) | Mandatory for accurate determination of enantiomeric excess and reaction progress. |

| Design of Experiments Software (e.g., JMP, MODDE, Minitab) | Critical for designing arrays, randomizing runs, performing ANOVA, and generating response surface models. |

Visualization of DoE Workflow & Pathway

Title: DoE Workflow for Cascade Optimization

Title: 3-Enzyme Cascade with Cofactor Regeneration

Solving Real-World Problems: Troubleshooting DoE in Complex Cascade Reactions

Application Notes: A DoE Framework for Cascade Optimization

Within the thesis "A Systematic Design of Experiments (DoE) Approach for Robust Multi-Enzyme Cascade Bioprocessing," three recurrent pitfalls are identified as primary causes of yield and productivity loss. Their mitigation is central to effective experimental design.

1. Enzyme Inactivation Kinetic instability of one enzyme can dictate the lifetime of the entire cascade. DoE moves beyond simple activity assays to model inactivation as a function of multiple stressors.

- Key Factors: Temperature, pH, shear force, co-solvent concentration, byproduct inhibitors.

- DoE Strategy: A full factorial or central composite design to model the half-life (t₁/₂) of each enzyme against critical abiotic factors, identifying overlapping stability windows.

Table 1: DoE Matrix for Inactivation Kinetics

| Factor | Low Level (-1) | High Level (+1) | Response Measured |

|---|---|---|---|

| Temperature | 25°C | 45°C | Apparent t₁/₂ (hr) |

| pH | 6.5 | 8.5 | Residual Activity (%) |

| [Co-solvent] | 5% v/v | 20% v/v | First-order k_inact (min⁻¹) |

| [Inhibitor] | 0 mM | 10 mM | Time to 50% activity loss |

Protocol 1: High-Throughput Inactivation Profiling

- Objective: To determine the operational stability of individual cascade enzymes under process-relevant conditions.

- Materials: Purified enzymes, reaction buffer stock, substrate stock, microplate reader with temperature control.

- Method:

- Prepare master mixes of each enzyme in the buffer conditions defined by the DoE matrix (e.g., 96-well format).

- Incplicate plates at designated temperatures with shaking.

- At time intervals (0, 15, 30, 60, 120 min), aliquot a sample from each well into a pre-prepared, optimal assay mix containing saturating substrate.

- Measure initial velocities (V₀) via absorbance/fluorescence.

- Fit residual activity (V₀,t / V₀,t=0) over time to a first-order decay model to calculate k_inact for each condition.

2. Unbalanced Flux Optimal cascade performance requires matched reaction velocities. DoE is used to titrate enzyme loading ratios to minimize intermediate accumulation while maximizing final product formation.

Table 2: DoE for Enzyme Loading Ratio Optimization

| Enzyme 1 Load (U/mL) | Enzyme 2 Load (U/mL) | Enzyme 3 Load (U/mL) | [Intermediate B] (mM) | Final Yield (%) |

|---|---|---|---|---|

| 1.0 | 1.0 | 1.0 | 2.5 ± 0.3 | 45 |

| 2.0 | 1.0 | 1.0 | 0.8 ± 0.1 | 78 |

| 1.0 | 2.0 | 1.0 | 4.1 ± 0.4 | 31 |

| 2.0 | 2.0 | 2.0 | <0.1 | 95 |

Protocol 2: Flux Balance Analysis via Stopped-Flow Sampling

- Objective: To dynamically profile intermediate concentrations and identify rate-limiting steps.

- Materials: Multi-enzyme cascade mix, quench solution (e.g., acid, organic solvent), HPLC or LC-MS.

- Method:

- Initiate the cascade reaction by adding the starting substrate to the complete enzyme mix.

- At precise time points (e.g., 0.5, 1, 2, 5, 10 min), withdraw an aliquot and immediately quench it.

- Centrifuge quenched samples to remove precipitated protein.

- Analyze supernatant for concentrations of starting material, all known intermediates, and final product using calibrated analytical methods (HPLC/LC-MS).

- Use time-course data to calculate instantaneous fluxes for each step.

3. Unmeasured Intermediate Buildup Toxic or inhibitory intermediates can form from side reactions or non-optimal flux. DoE coupled with inline analytics is essential for detection.

Protocol 3: Inline Monitoring for Intermediate Detection

- Objective: To identify and quantify unknown or suspected inhibitory intermediates in real-time.

- Materials: Bioreactor or flow cell, inline FTIR or Raman probe, multivariate analysis software.

- Method:

- Set up the cascade reaction in a vessel equipped with an inline spectroscopic probe.

- Collect spectral data continuously throughout the reaction time course.

- Use Principal Component Analysis (PCA) on the spectral time series to identify time points where the spectra deviate from the expected pathway.

- Isolate and identify compounds from these critical time points using preparative scale reactions and LC-MS/NMR.

- Add identified compounds to a DoE screening plate to test their inhibitory effects on each enzyme.

The Scientist's Toolkit

| Research Reagent / Material | Function in Cascade DoE |

|---|---|

| Phusion High-Fidelity DNA Polymerase | For error-free cloning of enzyme genes into expression vectors. |

| HisTrap HP Nickel Affinity Column | Standardized purification of His-tagged recombinant enzymes. |

| HaloTag Covalent Ligand Resin | For irreversible, oriented enzyme immobilization on solid supports. |

| Cytiva HiTrap Desalting Column | Rapid buffer exchange to create consistent enzyme stocks. |

| Sigma-Aldrich SUBSTRATE Libraries | For high-throughput kinetic screening of enzyme variants. |

| Promega NADP/NADPH-Glo Assay | Sensitive, luminescent detection of cofactor turnover. |

| Agilent InfinityLab HPLC Column | For quantitative analysis of substrates, intermediates, and products. |

| MATLAB Statistics and Machine Learning Toolbox | For designing DoE matrices and performing response surface modeling. |

Visualizations

DoE Optimization Workflow

Cascade Flux & Side Reaction

Within the broader thesis on Design of Experiments (DoE) for optimizing multi-enzyme cascades in synthetic biochemistry, statistical interpretation is paramount. Multi-enzyme systems are characterized by complex interactions between factors such as pH, temperature, cofactor concentrations, and enzyme ratios. This document provides Application Notes and Protocols for employing Analysis of Variance (ANOVA) and Regression Modeling to decode these interactions, transforming screening data into predictive, actionable models for cascade optimization.

Foundational Statistical Concepts for DoE

- ANOVA: Used to dissect the total variability in a response (e.g., product yield, total turnover number) into attributable sources. It tests the null hypothesis that means from different experimental conditions are equal, identifying which factors (e.g., Enzyme A concentration) and interactions (e.g., Enzyme A x pH) have statistically significant effects.

- Regression Analysis (Linear & Polynomial): Builds a quantitative model relating the response variable (Y) to the controlled factors (X's). For DoE, a polynomial model is often used:

Y = β₀ + ΣβᵢXᵢ + ΣβᵢⱼXᵢXⱼ + ΣβᵢᵢXᵢ² + ε, where β are coefficients, X are factors, and ε is error. This model quantifies the magnitude and direction of effects.

Application Notes: A Case Study on a 3-Enzyme Cascade

Objective: Optimize the final product yield of a 3-enzyme cascade (E1, E2, E3) converting substrate S to product P.

DoE Performed: A 2³ full factorial design with 2 central points (10 total runs). Factors: [E1] (low: 5 µM, high: 15 µM), pH (low: 6.8, high: 7.6), Mg²⁺ (low: 1 mM, high: 5 mM).

Table 1: Experimental Design Matrix and Results

| Run | [E1] (µM) | pH | [Mg²⁺] (mM) | Yield (%) |

|---|---|---|---|---|

| 1 | 5 | 6.8 | 1 | 12.4 |

| 2 | 15 | 6.8 | 1 | 38.7 |

| 3 | 5 | 7.6 | 1 | 18.9 |

| 4 | 15 | 7.6 | 1 | 52.1 |

| 5 | 5 | 6.8 | 5 | 15.1 |

| 6 | 15 | 6.8 | 5 | 35.3 |

| 7 | 5 | 7.6 | 5 | 22.4 |

| 8 | 15 | 7.6 | 5 | 48.9 |

| 9 (CP) | 10 | 7.2 | 3 | 33.8 |

| 10 (CP) | 10 | 7.2 | 3 | 32.1 |

Analysis Protocol:

- Model Fitting: Fit a linear regression model with interaction terms to the data in Table 1 using statistical software (e.g., R, Python statsmodels, JMP).

- ANOVA Table Construction: Generate an ANOVA table to assess significance.

Table 2: ANOVA Table for Yield Model

| Source | Sum Sq | df | Mean Sq | F-value | p-value |

|---|---|---|---|---|---|

| [E1] | 1852.1 | 1 | 1852.1 | 256.4 | <0.001 |

| pH | 270.8 | 1 | 270.8 | 37.5 | 0.002 |

| [Mg²⁺] | 9.6 | 1 | 9.6 | 1.33 | 0.298 |

| [E1] x pH | 36.1 | 1 | 36.1 | 5.00 | 0.070 |

| [E1] x [Mg²⁺] | 10.2 | 1 | 10.2 | 1.42 | 0.284 |

| pH x [Mg²⁺] | 1.2 | 1 | 1.2 | 0.17 | 0.697 |

| Residual | 36.1 | 5 | 7.2 |

Interpretation: [E1] and pH are highly significant (p<0.01). The [E1] x pH interaction is marginally significant (p=0.07), suggesting the effect of enzyme concentration depends on pH level.

- Final Model Interpretation:

The significant model (p < 0.001) after removing non-significant terms (α=0.1) is:

Yield (%) = 32.95 + 12.01*[E1] + 4.12*pH + 1.88*([E1]*pH)(Coded units: -1 for low, +1 for high level). Conclusion: Yield increases with higher [E1] and pH. The positive interaction coefficient indicates the synergistic effect of high [E1] and high pH is greater than their individual additive effects.

Visualization of Statistical Workflow & Interpretation

Diagram Title: Statistical Analysis Workflow for DoE

Diagram Title: Interaction Effect Interpretation Table

The Scientist's Toolkit: Research Reagent & Software Solutions

Table 3: Essential Materials for Enzyme Cascade DoE & Analysis

| Item/Category | Example/Product | Function in Protocol |

|---|---|---|

| Enzymes | Recombinant dehydrogenases, transaminases, kinases | The biocatalysts comprising the cascade. Purity and specific activity must be standardized. |

| Cofactors | NAD(P)H, ATP, PLP (Pyridoxal phosphate) | Essential co-substrates for many enzymes. Their concentration is a key DoE factor. |

| Buffers | HEPES, Tris, Phosphate buffers (varying pH) | Maintain precise reaction pH, a critical factor for enzyme activity and stability. |

| Metal Salts | MgCl₂, MnCl₂, KCl | Act as cofactors or stabilizers (e.g., Mg²⁺ for kinases). Concentration is a common DoE factor. |

| Analytical Standard | Pure final product (P) | Used to generate calibration curves for accurate yield quantification via HPLC/GC. |

| Statistical Software | JMP, Minitab, R (with DoE.base, rsm packages), Python (statsmodels, scikit-learn) |

Platform for designing experiments, performing ANOVA, regression, and generating response surface models. |

| Data Visualization | Graphviz, ggplot2 (R), matplotlib/seaborn (Python) | Creates clear diagrams of workflows and interaction plots for publication and presentation. |

Within the context of optimizing multi-enzyme cascade reactions for pharmaceutical synthesis, this document details the application of iterative Design of Experiments (DoE) as a strategic framework for navigating complex experimental landscapes. Sequential experimentation enables efficient resource allocation by iteratively building models and focusing experimental efforts on regions of interest, accelerating the path to optimal cascade performance (e.g., yield, productivity, purity).