Revolutionizing Biocatalysis: A Comprehensive Guide to 3D-Printed Reactor Design for Drug Discovery and Development

This article provides a detailed exploration of 3D-printed reactor technology for biocatalytic applications, tailored for researchers and drug development professionals.

Revolutionizing Biocatalysis: A Comprehensive Guide to 3D-Printed Reactor Design for Drug Discovery and Development

Abstract

This article provides a detailed exploration of 3D-printed reactor technology for biocatalytic applications, tailored for researchers and drug development professionals. It covers the foundational principles of additive manufacturing for reactor fabrication, examines methodological approaches for immobilizing enzymes and designing flow systems, addresses common troubleshooting and optimization challenges, and validates performance through comparative analysis with traditional methods. The full scope guides the reader from concept to implementation, highlighting how 3D printing enables precise control over reaction environments, accelerates process development, and unlocks new possibilities in synthesizing high-value pharmaceuticals and fine chemicals.

The Rise of Additive Manufacturing in Biocatalysis: Core Principles and Material Innovations

Application Notes: The Role of Biocatalysis in Modern Synthesis

Biocatalysis employs natural catalysts, such as enzymes or whole cells, to perform chemical transformations. It is central to sustainable chemistry, offering high selectivity, mild operational conditions, and reduced environmental impact. Key industrial applications include the synthesis of active pharmaceutical ingredients (APIs), chiral intermediates, and fine chemicals. For instance, over 70% of chiral pharmaceutical intermediates are now produced using biocatalytic methods, compared to ~30% a decade ago. However, widespread adoption is hampered by limitations in mass transfer, enzyme stability under process conditions, and scalability.

Advanced reactor design, particularly using 3D printing, addresses these bottlenecks by enabling geometries that maximize catalyst utilization and interfacial area, integrate unit operations, and provide precise control over microenvironmental conditions (e.g., pH, substrate concentration). This is the core thesis of our research: that tailored 3D-printed reactors are key to unlocking the full potential of biocatalysis.

Table 1: Comparative Performance of Conventional vs. Advanced Bioreactors for a Model Ketoreductase Reaction

| Parameter | Batch Stirred-Tank Reactor (STR) | Packed-Bed Reactor (PBR) | 3D-Printed Continuous-Flow Mesofluidic Reactor (Thesis Prototype) |

|---|---|---|---|

| Space-Time Yield (g L⁻¹ h⁻¹) | 12.5 | 45.2 | 118.7 |

| Enzyme Productivity (kg product kg⁻¹ enzyme) | 1,250 | 4,520 | 11,870 |

| Optical Purity (% ee) | 99.2 | 99.5 | 99.8 |

| Normalized Energy Input (kW m⁻³) | 1.0 (baseline) | 0.6 | 0.3 |

| Operational Stability (Half-life, days) | 7 | 21 | 45 |

Protocols

Protocol 2.1: Immobilization of Ketoreductase on 3D-Printed Monolith

Objective: To covalently immobilize a NADPH-dependent ketoreductase onto a 3D-printed epoxy-based monolith with internal lattice geometry for continuous-flow biocatalysis.

Materials:

- Monolith: 3D-printed epoxy resin structure (10 mm diameter x 50 mm length, 500 µm channel width).

- Enzyme: Recombinant Candida parapsilosis ketoreductase (CPKR), 10 mg/mL in 50 mM potassium phosphate buffer, pH 7.0.

- Activation Solution: 2% (v/v) glutaraldehyde in 0.1 M sodium carbonate buffer, pH 9.2.

- Quenching Solution: 1 M ethanolamine hydrochloride, pH 8.5.

- Wash Buffer: 50 mM potassium phosphate buffer, pH 7.0, containing 0.5 M NaCl.

Procedure:

- Monolith Activation: Connect the monolith to a peristaltic pump. Recirculate the glutaraldehyde activation solution at 0.5 mL/min for 2 hours at 25°C.

- Washing: Flush the monolith with 50 mL of deionized water at 2 mL/min to remove excess glutaraldehyde.

- Enzyme Immobilization: Recirculate the CPKR enzyme solution through the activated monolith at 0.2 mL/min for 18 hours at 4°C.

- Quenching: Flush with 20 mL of quenching solution at 1 mL/min for 1 hour to block unreacted aldehyde groups.

- Final Wash: Wash sequentially with 50 mL of Wash Buffer and 50 mL of standard reaction buffer (50 mM phosphate, pH 6.5).

- Activity Assay: Determine immobilization yield and activity by comparing protein concentration (Bradford assay) and initial reaction rate in a batch test before and after immobilization.

Protocol 2.2: Continuous-Flow Biocatalytic Reduction in a 3D-Printed Reactor

Objective: To perform the asymmetric reduction of ethyl 4-chloroacetoacetate to (S)-ethyl 4-chloro-3-hydroxybutyrate using the immobilized ketoreductase monolith in a cofactor-regenerating system.

Materials:

- Reactor System: Immobilized enzyme monolith (from Protocol 2.1) housed in a thermally jacketed 3D-printed module.

- Substrate Solution: 100 mM ethyl 4-chloroacetoacetate, 10 mM NADP⁺, 100 mM isopropanol (co-substrate for cofactor regeneration) in 50 mM potassium phosphate buffer, pH 6.5.

- Analytical: Chiral HPLC column (Chiralcel OD-H), hexane/isopropanol mobile phase.

Procedure:

- System Setup: Connect the substrate reservoir to the inlet of the enzyme module via HPLC tubing. Connect the module outlet to a fraction collector. Set the module temperature to 30°C via a circulating water bath.

- Reaction Initiation: Pump the substrate solution through the enzyme module at a defined flow rate (e.g., 0.1 mL/min). Allow system to stabilize for 30 minutes.

- Steady-State Operation: Collect effluent fractions over time. Analyze samples by chiral HPLC to determine conversion and enantiomeric excess.

- Parameter Optimization: Systematically vary flow rate (residence time) and substrate concentration to optimize space-time yield (see Table 1).

- Stability Assessment: Operate the system continuously for 500 hours, sampling periodically to monitor activity decay and determine operational half-life.

Diagrams

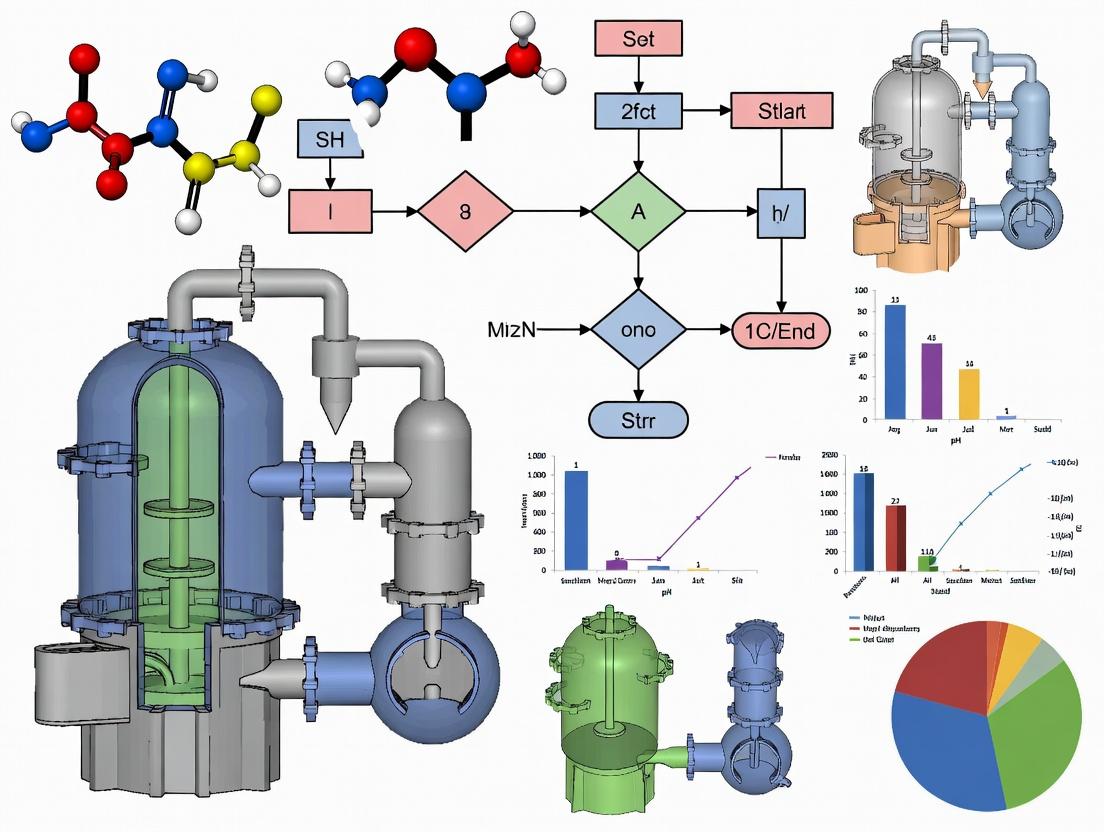

Title: Logic Flow: From Biocatalysis Challenges to 3D-Printed Solutions

Title: Enzyme & Cofactor Regeneration Pathway in Immobilized System

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for Biocatalytic Reactor Research

| Item Name / Solution | Function & Rationale |

|---|---|

| Chiral HPLC Columns (e.g., Chiralcel OD-H) | For accurate quantification of enantiomeric excess (% ee), the critical metric for asymmetric synthesis. |

| NADP⁺/NADPH Cofactor Systems | Essential redox cofactors for oxidoreductase enzymes; cost-effective in situ regeneration is required. |

| Epoxy or PEG-Based Photopolymer Resins | High-resolution, biocompatible materials for stereolithography (SLA) 3D printing of reactor prototypes. |

| Glutaraldehyde Crosslinking Solution | Standard reagent for activating hydroxylated surfaces and covalently immobilizing enzymes via lysine residues. |

| Recombinant Ketoreductase (e.g., CPKR, ADH-A) | Benchmark enzymes for asymmetric reduction, widely available and well-characterified for process development. |

| Cofactor Recycling Enzymes (G6PDH, FDH) | Provide alternative, efficient NAD(P)H regeneration systems from cheap sacrificial substrates (glucose, formate). |

| Continuous-Flow Pump Module (HPLC/Pertistaltic) | Provides precise, pulseless flow for residence time control in continuous biocatalysis experiments. |

The design and fabrication of reactors for biocatalytic applications require precise control over geometry, surface finish, and material properties to optimize enzyme immobilization, substrate flow, and product yield. Additive manufacturing (3D printing) enables the rapid prototyping and production of reactors with complex, tailored internal architectures (e.g., mixers, static baffles, packed-bed structures) that are difficult or impossible to achieve with traditional methods like milling or molding. This application note details the use of Stereolithography (SLA), Digital Light Processing (DLP), Fused Deposition Modeling (FDM), and PolyJet technologies specifically for creating reactors for biocatalysis research, providing protocols and comparisons to guide selection and implementation.

Technology Comparison & Quantitative Data

Table 1: Quantitative Comparison of 3D Printing Technologies for Reactor Fabrication

| Feature | SLA | DLP | FDM | PolyJet |

|---|---|---|---|---|

| Typical Resolution (XY) | 25-140 µm | 20-100 µm | 50-500 µm | 20-85 µm |

| Typical Resolution (Z) | 25-200 µm | 25-100 µm | 50-400 µm | 16-30 µm |

| Print Speed* | Medium | Fast (Full Layer) | Slow to Medium | Medium |

| Surface Finish | Excellent, Smooth | Excellent, Smooth | Good to Poor (Visible Layers) | Excellent, Very Smooth |

| Material Options | Photopolymers (Acrylates, Epoxies) | Photopolymers (Acrylates, Epoxies) | Thermoplastics (PLA, ABS, PP, PEEK) | Multi-Material Photopolymers |

| Biocompatibility | Select Biocompatible Resins Available | Select Biocompatible Resins Available | PLA, PP, PETG are Generally Suitable | Select Biocompatible Photopolymers Available |

| Chemical Resistance | Moderate to High (Resin-Dependent) | Moderate to High (Resin-Dependent) | Low to High (Material-Dependent) | Low to Moderate |

| Max. Operating Temp. | ~80-120°C (Post-Cured) | ~80-120°C (Post-Cured) | ~60°C (PLA) to ~250°C (PEEK) | ~50-70°C |

| Relative Cost (Machine) | Medium | Medium | Low | High |

| Relative Cost (Material) | High | High | Low | Very High |

| Key Advantage for Reactors | High-resolution, transparent parts for flow visualization. | Fast printing of small, high-resolution parts. | Low-cost, accessible; wide range of engineering thermoplastics. | Multi-material printing (e.g., rigid channels + flexible seals). |

| Primary Limitation | Limited material strength; requires post-processing. | Build size limited by projector resolution. | Anisotropic strength; poor seal for high pressure. | Lower chemical/thermal resistance; high material cost. |

*Speed is highly dependent on part size and print settings.

Experimental Protocols for Reactor Fabrication & Testing

Protocol 3.1: Design & Pre-Print Preparation

- Design (CAD): Design the reactor (e.g., continuous stirred-tank, packed-bed, microfluidic) using CAD software (e.g., SolidWorks, Fusion 360). Incorporate standard fittings (e.g., Luer lock, NPT threads) or design custom connectors.

- Critical Considerations:

- Wall Thickness: Ensure minimum wall thickness ≥ 1.0 mm for SLA/DLP/PolyJet and ≥ 1.5 mm for FDM to withstand fluid pressure.

- Support Structures: Design overhangs >45° will require supports (auto-generated in slicer software). For fluidic channels, orient model to minimize supports inside channels.

- Sealing: Design for O-rings or gaskets at sealing interfaces, or utilize PolyJet's multi-material capability to print gaskets directly.

- File Export: Export the final design as an STL or 3MF file.

Protocol 3.2: Printing & Post-Processing (SLA/DLP Specific)

Materials: Biocompatible, chemical-resistant resin (e.g., Formlabs BioMed or Rigid Resins, Anycubic Eco Resin); Isopropyl Alcohol (IPA, ≥99%); PPE (nitrile gloves, safety glasses). Equipment: SLA/DLP printer, wash station (e.g., ultrasonic bath), post-curing station (UV chamber).

- Slicing: Import STL into printer's slicer (e.g., Chitubox, PreForm). Orient to minimize cross-sectional area and supports. Generate supports, slice, and send file to printer.

- Printing: Follow manufacturer instructions. Ensure resin tank is clean and filled.

- Post-Processing:

- Cleaning: Remove part from build plate. Submerge in IPA bath for 3-5 minutes to remove uncured resin. Use gentle agitation or ultrasonic bath. For complex channels, flush with IPA using a syringe.

- Support Removal: Carefully remove all support structures using flush cutters.

- Post-Curing: Place the part in a UV curing chamber. Cure for 15-30 minutes per side, or as per resin specifications, to achieve final mechanical properties and biocompatibility.

Protocol 3.3: Printing & Post-Processing (FDM Specific)

Materials: Biocompatible filament (e.g., PLA, PP, PETG). Equipment: FDM 3D printer, build plate adhesive (glue stick, painter's tape).

- Slicing: Import STL into slicer (e.g., Ultimaker Cura, PrusaSlicer). Key parameters for reactors:

- Layer Height: 0.1-0.2 mm for better seal.

- Wall/Shell Count: ≥ 3 perimeters.

- Infill: 100% (solid) for pressure-containing parts.

- Print Temperature & Bed Temperature: Set per filament specifications.

- Enable Retraction: To prevent oozing in internal channels.

- Printing: Level build plate, apply adhesive, and start print.

- Post-Processing: Remove part. Visually inspect for leaks. Light sanding of sealing surfaces may improve seal. For PLA, annealing (heat treatment) can improve temperature resistance and seal.

Protocol 3.4: Reactor Sealing & Pressure Testing Protocol

Objective: To ensure the printed reactor is leak-proof under operational conditions. Materials: Printed reactor, tubing, syringe pump, pressure gauge, water, food dye.

- Assembly: Connect inlet/outlet ports to tubing using appropriate fittings (e.g., barbed fittings sealed with epoxy if not printed-in).

- Static Leak Test: Fill the reactor with dyed water via syringe. Seal all ports. Place reactor on dry paper towel. Apply gentle internal pressure with syringe. Monitor for leaks on paper towel for 15 minutes.

- Dynamic Pressure Test: Connect reactor in-line with a syringe pump and a downstream pressure gauge. Pump water at a set flow rate (e.g., 1-5 mL/min) while monitoring pressure. Gradually increase flow rate to the maximum intended operational pressure (target 2-3 bar for typical printed reactors). Hold for 30 minutes and monitor for pressure drop or visual leaks.

- Documentation: Record maximum held pressure and any failure points.

Visualization of Workflow and Material Selection

Workflow for Selecting 3D Printing Technology for Biocatalytic Reactors

General Workflow for 3D Printing a Functional Reactor

The Scientist's Toolkit: Key Research Reagent Solutions & Materials

Table 2: Essential Materials for 3D-Printed Biocatalytic Reactor Research

| Item | Function/Application | Example Brands/Types |

|---|---|---|

| Biocompatible SLA/DLP Resin | For printing reactors contacting biocatalysts (enzymes, cells). Must be non-cytotoxic and suitable for post-print sterilization. | Formlabs BioMed Amber, Dental SG; Anycubic Plant-Based Eco Resin (for prototyping). |

| Chemical-Resistant Resin | For reactors using organic solvents or harsh reagents in biocatalytic steps (e.g., transesterification). | Formlabs Rigid 10K, Loctite 3D IND405. |

| PP or PEEK Filament (FDM) | Polypropylene (PP) offers good chemical resistance. Polyetheretherketone (PEEK) offers exceptional thermal/chemical resistance for demanding applications. | Ultimaker PP, 3DXtech PEEK. |

| Silicone Sealant/Epoxy | For sealing threaded or bonded joints on FDM or SLA printed reactors to prevent leaks. | FDA-compliant silicone sealant; two-part epoxy (e.g., Devcon). |

| IPA (≥99% Purity) | Essential washing agent for removing uncured resin from SLA/DLP/PolyJet prints. | Lab-grade isopropyl alcohol. |

| UV Post-Curing Chamber | To fully cure photopolymer resins after printing, achieving final mechanical strength and biocompatibility. | Formlabs Form Cure, Anycubic Wash & Cure. |

| Syringe Pump & Pressure Sensor | For controlled flow testing, operational use, and pressure integrity validation of printed reactors. | Cole-Parmer syringe pumps; digital pressure gauges. |

| Enzyme Immobilization Reagents | To functionalize the internal surface of printed reactors for biocatalysis (e.g., glutaraldehyde for cross-linking, (3-Aminopropyl)triethoxysilane (APTES) for surface amination). | Sigma-Aldrich. |

Within the broader thesis on advanced 3D-printed reactor design for biocatalytic applications in pharmaceutical research, the selection of construction materials is paramount. The performance, reproducibility, and scalability of biocatalytic processes—such as enzyme-mediated synthesis of chiral intermediates or active pharmaceutical ingredients (APIs)—are directly dictated by three intertwined material properties: Biocompatibility, Chemical Resistance, and Surface Properties. This document outlines application notes and detailed experimental protocols to evaluate these characteristics for novel 3D-printing polymers and resins, ensuring their suitability for next-generation bioreactor systems.

Application Notes

Biocompatibility

Biocompatibility ensures the material does not adversely affect the biocatalyst (e.g., free enzyme, immobilized enzyme, or whole cell). Leachables from the printed material can denature proteins or inhibit catalytic activity.

Key Findings from Recent Literature (2023-2024):

- Enzyme Activity Retention: Studies on common 3D-printing resins show that post-processing is critical. UV-cured methacrylate-based resins can leach photo-initiators (e.g., phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide) which reduce enzyme activity by up to 40-60% without thorough cleaning. Proper post-curing and solvent extraction can improve activity retention to >90%.

- Cell Viability: For whole-cell biocatalysis in 3D-printed chambers, materials like medical-grade polypropylene (PP) and polyethylene terephthalate glycol (PETG) show >95% mammalian cell viability over 72 hours, whereas some stereolithography (SLA) resins exhibit cytotoxicity unless coated with a biocompatible layer (e.g., poly-L-lysine or silicone).

Chemical Resistance

Reactors must withstand varied conditions: aqueous buffers (pH 2-11), organic solvents (e.g., methanol, ethyl acetate for substrate/product solubility), and temperatures from 20°C to 60°C.

Key Findings from Recent Literature (2023-2024):

- Solvent Exposure: Accelerated aging tests (30-day immersion) reveal significant swelling (>5% mass change) in polylactic acid (PLA) when exposed to ethyl acetate, rendering it unsuitable. Acrylonitrile butadiene styrene (ABS) shows better resistance (<1% mass change) to alkanes but poor resistance to acetone.

- Hydrolytic Stability: Polypropylene (PP) and fluoropolymers (like PVDF) exhibit superior long-term hydrolytic stability with no significant loss in mechanical properties after 6 months in buffer, compared to polycarbonate (PC) which can undergo hydrolysis at elevated pH and temperature.

Surface Properties

Surface energy, roughness, and chemistry dictate fouling, cleaning efficiency, and the success of enzyme or cell immobilization.

Key Findings from Recent Literature (2023-2024):

- Fouling & Cleanability: Surface roughness (Ra) > 10 µm significantly increases protein adsorption and biofilm formation. 3D-printed parts with Ra < 1 µm, achieved via vapor smoothing or high-resolution printing, reduce fouling by >70%.

- Immobilization Yield: Aminosilane surface modification of printed parts increases covalent enzyme immobilization yield by 3-5 fold compared to untreated surfaces. The density of reactive surface groups, quantified via colorimetric assays (e.g., with picrylsulfonic acid), is a critical control parameter.

Table 1: Quantitative Comparison of Selected 3D-Printing Materials for Biocatalytic Reactors

| Material (Printing Method) | Biocompatibility (Enzyme Activity Retention %) | Chemical Resistance (Mass Change in EtOAc, 7 days %) | Surface Roughness, Ra (µm) | Recommended Application Scope |

|---|---|---|---|---|

| Medical PLA (FDM) | 85-90 | +8.5 | 5-15 | Single-use, aqueous-phase batch reactors |

| ABS (FDM) | 75-80* | +0.8 | 10-25 | Organic/aqueous two-phase systems (avoid ketones) |

| PETG (FDM) | 90-95 | +1.2 | 5-12 | Reusable flow reactor components |

| PP (FDM) | >95 | <+0.5 | 8-20 | Chemically resistant liners & fittings |

| Biocompatible Resin (SLA) | >90 | +3.0 | 0.5-2.0 | High-resolution, microfluidic enzyme reactors |

| PVDF (Specialized) | >95 | <+0.1 | 20-50* | Highly corrosive chemical environments |

Requires extensive post-processing and leaching tests. *After validated post-cure and extraction protocol. Can be surface finished to Ra < 2 µm.

Experimental Protocols

Protocol 3.1: Assessing Leachate Impact on Enzyme Activity

Objective: Quantify the effect of material leachables on a model enzyme's catalytic activity. Workflow: Material Sample Preparation → Leachate Generation → Incubation with Enzyme → Activity Assay.

Diagram Title: Enzyme Leachate Bioassay Workflow

Materials & Reagents:

- Test Material Coupons: 3D-printed, post-processed (e.g., cleaned, UV-cured) samples (1 cm² surface area/mL buffer).

- Control Buffer: Relevant assay buffer (e.g., 50 mM Tris-HCl, pH 7.5).

- Model Enzyme: Commercially available, well-characterized enzyme (e.g., Candida antarctica Lipase B).

- Assay Substrate: Para-nitrophenyl palmitate (p-NPP) or other chromogenic/fluorogenic substrate.

- Microplate Reader: For kinetic absorbance/fluorescence measurements.

Procedure:

- Leachate Generation: Immerse material coupons in control buffer (1 mL buffer per cm² surface area). Incubate with agitation (100 rpm) at 37°C for 24 hours. Filter supernatant (0.22 µm).

- Enzyme Incubation: Mix 100 µL of leachate with 100 µL of enzyme solution (0.1 mg/mL in control buffer). Incubate at 4°C for 18 hours. Prepare a control using pure buffer instead of leachate.

- Activity Assay: In a 96-well plate, combine 20 µL of incubation mixture with 180 µL of pre-warmed substrate solution. Immediately measure absorbance at 405 nm every 30 seconds for 10 minutes.

- Calculation: Calculate initial reaction rates (V0). Express activity retention as:

(V0_leachate / V0_control) * 100%.

Protocol 3.2: Chemical Resistance via Immersion Test

Objective: Determine mass change and visual degradation of materials upon solvent exposure. Workflow: Sample Conditioning → Solvent Immersion → Gravimetric Analysis.

Diagram Title: Chemical Immersion Test Protocol

Materials & Reagents:

- Test Solvents: Representative solvents (e.g., Water, Ethanol, Ethyl Acetate, Toluene, 1 M NaOH, 1 M HCl).

- Analytical Balance: Precision ±0.01 mg.

- Sealed Glass Vials: Chemically resistant (e.g., borosilicate).

- Drying Oven: Set to 50°C (or below material Tg).

Procedure:

- Conditioning: Dry printed samples (e.g., 10 mm x 10 mm x 2 mm) in an oven at 50°C for 24 hours. Cool in a desiccator.

- Initial Mass (M₀): Weigh each sample precisely.

- Immersion: Immerse each sample in 10 mL of solvent in a sealed vial. Maintain at constant temperature (e.g., 25°C). Use triplicates.

- Final Mass (M₁): After the set period (e.g., 7 days), remove sample, rinse with fresh solvent, pat dry, and weigh immediately.

- Analysis: Calculate percent mass change. Inspect for visual defects. A change >1% typically indicates poor compatibility.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Material Characterization in Biocatalytic Reactor Development

| Item | Function in Protocols | Example Product/Chemical |

|---|---|---|

| Model Enzyme | Provides a standardized, sensitive biological probe to test for leachable toxicity or inhibition. | Candida antarctica Lipase B (CALB), Lysozyme. |

| Chromogenic Assay Substrate | Enables rapid, quantitative measurement of enzyme activity post-exposure to material. | Para-Nitrophenyl Palmitate (p-NPP) for lipases/esterases. |

| Medical-Grade 3D-Printing Resin | A benchmark material with documented biocompatibility for comparative studies. | Somos WaterShed XC 11122 (Formlabs Dental SG Resin). |

| Surface Profilometer | Quantifies surface roughness (Ra), a key parameter influencing fouling and cleanability. | Stylus-based or optical profilometer. |

| Aminosilane Coupling Agent | For surface modification studies to enhance enzyme immobilization capacity. | (3-Aminopropyl)triethoxysilane (APTES). |

| Extraction Solvents | Used in post-processing protocols to remove uncured monomers and oligomers from printed parts. | Isopropanol, Ethanol (for rinsing). |

| Fluorescent Stain (for Biofilm) | Visualizes and quantifies protein/cell adhesion on material surfaces. | Syto 9 / Propidium Iodide for live/dead cells; FITC for protein. |

| pH-Stable Buffer Salts | For creating a range of biologically relevant chemical environments for resistance testing. | Phosphate, Tris, Citrate buffer salts. |

This document is framed within a broader thesis on 3D-printed reactor design for biocatalytic applications. The primary objective is to leverage additive manufacturing to create purpose-built geometries that optimize biocatalyst performance (e.g., immobilized enzymes, whole cells) by enhancing mass transfer, surface-to-volume ratio, and flow dynamics, ultimately advancing research in synthetic chemistry and drug development.

Comparative Analysis of Reactor Geometries

The performance of a reactor geometry is primarily dictated by its surface area to volume (SA:V) ratio and its impact on key hydrodynamic parameters. These parameters directly influence biocatalytic efficiency by affecting substrate-catalyst contact time and pressure drop. The table below summarizes quantitative data for common and advanced 3D-printable geometries.

Table 1: Comparative Metrics of 3D-Printed Reactor Geometries for Biocatalysis

| Geometry Type | Typical SA:V (mm⁻¹) | Porosity (%) | Relative Pressure Drop | Key Biocatalytic Advantage | Typical Fabrication Method |

|---|---|---|---|---|---|

| Simple Straight Channel | 0.5 - 2 | N/A (Open) | Very Low | Laminar flow, easy modeling, minimal clogging. | FDM, SLA, DLP |

| Serpentine/Spiral Channel | 2 - 5 | N/A (Open) | Low to Medium | Enhanced mixing via Dean vortices, increased path length. | SLA, DLP, PolyJet |

| Packed-Bed Mimic (e.g., Gyroid) | 10 - 50 | 50 - 80 | Medium to High | Extreme SA:V, excellent radial mixing, mimics random packing. | SLA, DLP, SLS (high-res) |

| Monolith (Parallel Channels) | 5 - 15 | 70 - 90 | Low | Low backpressure, high throughput, uniform flow distribution. | DLP, micro-SLA |

| Fiber/Tubular Bundle | 8 - 25 | 60 - 85 | Medium | Good mechanical stability, high interfacial area. | Custom DLP, FDM with soluble support |

Data synthesized from recent literature on 3D-printed flow reactors (2023-2024). SA:V and porosity are highly dependent on print resolution and design parameters.

Experimental Protocols

Protocol 3.1: Digital Design and Printing of Reactor Geometries

Objective: To fabricate a test suite of reactor geometries using stereolithography (SLA).

- Design: Using CAD software (e.g., Fusion 360), create models of a straight channel (1mm diameter, 100mm length), a serpentine channel (equivalent length), and a gyroid-packed bed (10mm diameter, 20mm length, 2mm unit cell size). Export as

.STL. - Slicing: Import

.STLfiles into printer software (e.g., Chitubox). Orient models to minimize print failures and supports. Use layer height of 50µm for high resolution. - Printing: Use a bio-compatible, high-resolution resin (e.g., Formlabs BioMed Clear). Perform print according to manufacturer instructions.

- Post-Processing: Wash printed reactors in isopropanol (2 x 5 min) to remove uncured resin. Cure in a UV oven (365 nm, 60°C) for 30 minutes.

Protocol 3.2: Immobilization of β-Galactosidase in a 3D-Printed Monolith

Objective: To covalently immobilize an enzyme onto the surface of a 3D-printed methacrylate-based monolith.

- Surface Activation: Flush the printed monolith with 10 mL of 2M NaOH at 0.5 mL/min to hydrolyze ester groups, generating surface hydroxyls. Rinse with 20 mL DI water.

- Silanization: Flush with 10 mL of (3-aminopropyl)triethoxysilane (APTES) solution (5% v/v in anhydrous toluene) at 0.2 mL/min. Incubate statically for 2 hours at 70°C. Wash sequentially with toluene and ethanol.

- Glutaraldehyde Activation: Flush with 10 mL of 2.5% glutaraldehyde in phosphate buffer (0.1 M, pH 7.0) at 0.2 mL/min. Incubate for 1 hour at room temperature. Wash with buffer to remove excess crosslinker.

- Enzyme Coupling: Circulate a solution of β-galactosidase (5 mg/mL in 0.1 M phosphate buffer, pH 7.0) through the activated monolith at 0.1 mL/min for 12 hours at 4°C.

- Quenching & Storage: Flush with 20 mL of buffer to remove unbound enzyme. Store the functionalized reactor in assay buffer at 4°C.

Protocol 3.3: Evaluating Hydraulic Performance and Biocatalytic Conversion

Objective: To characterize pressure drop and substrate conversion across different reactor geometries.

- Hydraulic Setup: Connect the reactor to an HPLC pump and a pressure sensor. Use DI water as the fluid.

- Pressure Drop Measurement: For each geometry, record the pressure at flow rates from 0.1 to 2.0 mL/min. Plot pressure drop (ΔP) vs. flow rate (Q).

- Biocatalytic Assay: For an enzyme-immobilized reactor, pump a solution of substrate (e.g., ONPG for β-galactosidase, 2 mM in buffer) through the reactor at a set flow rate.

- Analysis: Collect effluent at timed intervals. Measure product concentration (e.g., ortho-nitrophenol absorbance at 420 nm). Calculate conversion percentage.

- Data Fitting: Model conversion vs. residence time to determine apparent reaction kinetics for each geometry.

Visualizations

Title: 3D-Printed Biocatalytic Reactor Design Workflow

Title: Enzyme Covalent Immobilization Reaction Pathway

The Scientist's Toolkit

Table 2: Key Research Reagent Solutions for 3D-Printed Biocatalytic Reactors

| Item | Function in Research | Example/Note |

|---|---|---|

| High-Resolution Biocompatible Resin | Primary material for printing reactors compatible with aqueous/biologic systems. | Formlabs BioMed Clear, Dental SG. Ensures no inhibitor leaching. |

| (3-Aminopropyl)triethoxysilane (APTES) | Coupling agent for introducing amine functional groups onto glass/polymer surfaces. | Enables subsequent covalent enzyme attachment. Use anhydrous conditions. |

| Glutaraldehyde (25% Solution) | Homobifunctional crosslinker for coupling amine-bearing enzymes to amine-functionalized surfaces. | Forms stable Schiff base linkages. Handle in fume hood. |

| Enzyme of Interest (Lyophilized) | The biocatalyst (e.g., lipase, transaminase). Critical for target reaction. | Select for stability, specific activity. Recombinant purity often required. |

| Chromogenic/Nitrogeic Substrate | Allows for facile, quantitative assay of immobilized enzyme activity. | e.g., pNPG for β-glucosidase, ONPG for β-galactosidase. |

| Phosphate Buffered Saline (PBS), 0.1M, pH 7.4 | Standard buffer for immobilization steps and biochemical assays. | Maintains enzyme stability and consistent reaction conditions. |

| Peristaltic or Syringe Pump | Provides precise, pulseless flow for reactor characterization and continuous operation. | Essential for residence time control and kinetic studies. |

| UV-Vis Flow Cell & Spectrophotometer | Enables real-time, in-line monitoring of product formation during continuous flow reactions. | Key for rapid process optimization and kinetic data acquisition. |

The Synergy Between Enzyme Engineering and Tailored 3D-Printed Microenvironments

Application Notes

The integration of enzyme engineering and 3D printing enables the creation of bespoke biocatalytic reactors with unparalleled control over reaction parameters. This synergy addresses key limitations in traditional batch biocatalysis, such as enzyme instability, mass transfer constraints, and difficulties in scaling. Below are key application notes demonstrating this convergence.

Application Note 1: Immobilization of Engineered PET Hydrolases in 3D-Printed Flow Reactors for Plastic Depolymerization

- Objective: Enhance the continuous degradation of polyethylene terephthalate (PET) using engineered, thermostable PETase variants.

- Key Findings: A 3D-printed polypropylene reactor with a triply periodic minimal surface (TPMS) geometry was functionalized with polydopamine to covalently immobilize an engineered FAST-PETase variant.

- Quantitative Data Summary:

| Parameter | Free Enzyme (Batch) | Immobilized Enzyme (3D-Printed Flow Reactor) | Improvement Factor |

|---|---|---|---|

| Operational Stability (Half-life at 40°C) | 48 hours | > 240 hours | >5x |

| PET Conversion Yield (72h) | 45% | 92% | ~2x |

| Productivity (mg TPA / mg enzyme) | 550 | 2100 | ~3.8x |

| Reusability (Cycles to 50% activity) | Not applicable | 15 cycles | N/A |

Application Note 2: 3D-Printed Multi-Enzyme Cascade Reactors for Chiral Amine Synthesis

- Objective: Perform efficient, multi-step synthesis of a chiral API intermediate using spatially organized enzyme cascades.

- Key Findings: A modular reactor was printed using a biocompatible resin. Separate compartments were loaded with an engineered transaminase (ATA-117 variant) and a lactate dehydrogenase (LDH) for cofactor regeneration, connected by controlled microchannels.

- Quantitative Data Summary:

| Parameter | Mixed Free Enzymes | 3D-Printed Compartmentalized Reactor |

|---|---|---|

| Overall Conversion | 78% | 99% |

| Product Enantiomeric Excess (ee) | 95% | >99.5% |

| Total Space-Time Yield (g L⁻¹ day⁻¹) | 12.4 | 41.7 |

| Byproduct Formation | 15% | <2% |

Application Note 3: Oxygen-Managed Microenvironments for Engineered P450 Monoxygenases

- Objective: Overcome oxygen mass transfer limitations in the oxyfunctionalization of complex terpenes.

- Key Findings: A gas-permeable polydimethylsiloxane (PDMS) reactor was printed with internal lattice structures. An engineered P450BM3 variant (with increased H₂O₂ tolerance) was encapsulated in a gelatin-based bioink within this structure.

- Quantitative Data Summary:

| Parameter | Conventional Stirred-Tank | 3D-Printed O₂-Managed Reactor |

|---|---|---|

| Oxygen Transfer Rate (OTR, mmol L⁻¹ h⁻¹) | 8.5 | 35.2 |

| Product Titer (mg L⁻¹) | 120 | 605 |

| Total Turnover Number (TTN) | 4,500 | 22,000 |

Experimental Protocols

Protocol 1: Fabrication and Functionalization of a TPMS Reactor for Enzyme Immobilization

Objective: To create a 3D-printed reactor with high surface area for covalent enzyme attachment. Materials: See "The Scientist's Toolkit" below. Method:

- Reactor Design & Printing: Design a gyroid-type TPMS structure (5 cm³) using CAD software. Export as an STL file. Print using a fused deposition modeling (FDM) printer with polypropylene filament (nozzle: 0.4 mm, layer height: 0.1 mm, 100% infill).

- Surface Activation: Place the printed reactor in a plasma cleaner for 5 minutes (air, 100 W). Immediately submerge it in a 2 mg/mL dopamine solution in 10 mM Tris-HCl buffer (pH 8.5). Agitate gently for 18 hours at room temperature.

- Polydopamine Coating: Remove the reactor and rinse thoroughly with deionized water. A gray coating confirms polydopamine (PDA) deposition.

- Enzyme Immobilization: Incubate the PDA-coated reactor with 5 mL of 1 mg/mL engineered enzyme solution in 0.1 M phosphate buffer (pH 7.4) for 12 hours at 4°C with gentle shaking.

- Washing & Storage: Wash the reactor with 20 mL of buffer to remove unbound enzyme. Store at 4°C in storage buffer until use. Determine immobilization yield via Bradford assay on the initial and flow-through solutions.

Protocol 2: Operation of a Compartmentalized Cascade Reactor

Objective: To conduct a continuous asymmetric synthesis using spatially separated enzymes. Method:

- Reactor Assembly: Print a two-chamber reactor (1 mL each chamber) with an interconnecting channel (500 µm diameter) using a high-resolution stereolithography (SLA) printer with a PEGDA-based resin. Post-cure and wash according to manufacturer instructions.

- Enzyme Loading: In Chamber A, mix 50 mg of lyophilized engineered transaminase with 1 mL of a 2% (w/v) agarose solution at 40°C and allow to gel. Fill Chamber B similarly with LDH and catalase (to degrade H₂O₂ byproduct).

- Reactor Setup: Connect Chamber A inlet to substrate feed (20 mM prochiral ketone, 25 mM alanine donor, 0.1 mM PLP in 0.1 M Tris-HCl, pH 8.0). Connect Chamber B inlet to a separate co-substrate feed (10 mM NAD⁺ in buffer). Use syringe pumps for both feeds (flow rate: 0.1 mL/min total).

- Operation & Monitoring: Connect the outlets to a fraction collector. Monitor product formation in Chamber A effluent via HPLC. Adjust relative flow rates to optimize residence time in each chamber.

Protocol 3: Bioprinting of Enzyme-Laden Hydrogels in Gas-Permeable Architectures

Objective: To entrap oxygen-sensitive enzymes in a controlled, oxygen-rich microenvironment. Method:

- Bioink Preparation: Dissolve 8% (w/v) gelatin and 2% (w/v) alginate in 0.1 M HEPES buffer (pH 7.2) at 40°C. Cool to 25°C and mix with an equal volume of engineered P450 enzyme solution (10 mg/mL) and 10 mM CaCl₂. Keep on ice.

- Extrusion Bioprinting: Load the bioink into a sterile cartridge. Print a 3D lattice structure (15 mm x 15 mm x 2 mm) directly into a pre-printed gas-permeable PDMS well. Use a pneumatic dispensing system (pressure: 15 kPa, nozzle: 22G, stage temp: 15°C).

- Cross-linking: After printing, immerse the structure in 100 mM CaCl₂ solution for 10 minutes to ionically cross-link the alginate.

- Reaction Initiation: Submerge the printed hydrogel structure in the substrate solution (e.g., 5 mM amorpha-4,11-diene in 0.1 M potassium phosphate, pH 7.4). Place the entire PDMS well in a chamber under gentle oxygen flow (1 standard cubic centimeter per minute). Monitor product by GC-MS.

Visualizations

Title: Synergy Workflow for Biocatalytic Reactor Design

Title: Protocol for 3D-Printed Enzyme Reactor Fabrication

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Context | Example/Specification |

|---|---|---|

| Engineered Enzyme Variants | Core biocatalyst with enhanced properties (thermostability, activity, solvent tolerance). | FAST-PETase, ATA-117-Rd11, P450BM3-A82F/F87V. |

| Functionalized 3D-Printing Resins | Enable covalent enzyme attachment post-printing. | PEGDA-MA (poly(ethylene glycol) diacrylate-methacrylate), Polydopamine-coated filaments. |

| Gas-Permeable Elastomers | Facilitate oxygen supply for oxidoreductases. | Sylgard 184 PDMS, 3D-printable silicone resins. |

| Shear-Thinning Bioinks | Allow extrusion printing while maintaining enzyme activity. | Gelatin-Alginate blends, PEG-based hydrogels with rheology modifiers. |

| Cross-linking Agents | Stabilize printed hydrogel structures. | Calcium chloride (for alginate), microbial transglutaminase (for gelatin). |

| Coenzyme/Substrate Solutions | Drive enzymatic reactions in continuous flow. | NAD(P)H/NAD(P)+ stocks, amino donor solutions (e.g., isopropylamine, alanine). |

| Immobilization Linkers | Provide chemical handles for stable enzyme fixation. | Glutaraldehyde, N-Hydroxysuccinimide (NHS) esters, Epoxy-activated resins. |

From CAD to Catalyst: A Step-by-Step Workflow for Fabricating and Implementing 3D-Printed Bioreactors

The design of 3D-printed reactors for biocatalysis requires the integration of advanced software tools and the precise optimization of critical fluid dynamic parameters. Within a broader thesis on advanced reactor design, this phase dictates reactor performance by influencing enzyme stability, substrate conversion, and product yield. Computational Fluid Dynamics (CFD) simulations are central to predicting and controlling shear stress, mixing efficiency, and residence time distribution (RTD) before committing to physical fabrication via additive manufacturing. This protocol details the application notes for this integrated digital design process.

Key Software Tools for Design and Simulation

Table 1: Essential Software for 3D-Printed Biocatalytic Reactor Design

| Software Category | Specific Tool(s) | Primary Function in Design Phase | Relevance to Biocatalysis |

|---|---|---|---|

| Computer-Aided Design (CAD) | SolidWorks, Fusion 360, FreeCAD, nTopology | 3D geometry creation of reactor internals (static mixers, channels). Enables design for additive manufacturing (DFAM). | Creation of complex, tortuous paths to enhance mixing and control residence time for viscous biocatalytic slurries. |

| Computational Fluid Dynamics (CFD) | ANSYS Fluent, COMSOL Multiphysics, OpenFOAM | Solving Navier-Stokes equations to simulate flow, shear stress, mixing, and concentration fields. | Predicting local shear stresses that may deactivate shear-sensitive enzymes or cells. Visualizing substrate dispersion. |

| Reactor Network Analysis | COMSOL (with Reaction Engineering), Python (Cantera, SciPy) | Modeling RTD and simplified kinetics to estimate conversion and selectivity. | Coupling fluid dynamics with Michaelis-Menten or more complex kinetic models for biotransformations. |

| Slicing & 3D Printing Prep | PrusaSlicer, Ultimaker Cura, Formlabs PreForm | Translating CAD to printer instructions (G-code), optimizing print orientation, supports. | Ensuring printed reactor geometry (e.g., surface roughness, channel fidelity) matches designed parameters. |

Protocol for Integrated CFD and Kinetic Modeling

Protocol 3.1: Coupled Shear Stress and Reaction Performance Analysis

Objective: To predict the impact of reactor geometry-induced shear stress on the apparent activity of a shear-sensitive enzyme (e.g., lipase, cellulase) in a continuous 3D-printed packed-bed reactor.

Materials (Digital Toolkit):

- CAD file of proposed reactor design (.STEP format).

- ANSYS Fluent or COMSOL Multiphysics software with "Laminar Flow" and "Species Transport" modules.

- Kinetic parameters (Km, Vmax) for the target enzyme.

- Physicochemical properties of reaction mixture (density, viscosity).

Procedure:

- Geometry Import & Meshing: Import the reactor CAD model. Generate a computational mesh, applying refinements near walls and packing elements. Aim for a mesh independence study (see Table 2).

- Boundary Conditions: Set inlet boundary to a defined volumetric flow rate (Q). Set outlet to pressure-outlet. Walls are set to no-slip conditions.

- Material Properties: Define fluid properties (e.g., aqueous solution, ρ ~1000 kg/m³, μ ~0.001 Pa·s).

- Shear Stress Calculation: Solve for the velocity field. Compute wall shear stress (τ_w) and the spatial distribution of shear rate (γ˙) within the fluid.

- Enzyme Activity Coupling: Implement a user-defined function (UDF) or reaction rate modifier that scales the local reaction rate based on the local shear rate. For example: k_local = k_ideal / (1 + (γ˙ / γ˙_crit)^2), where γ˙_crit is a critical shear rate for deactivation.

- Species Transport Simulation: Activate species transport. Define inlet substrate concentration. Implement the modified Michaelis-Menten kinetics as a source term.

- Simulation & Analysis: Run the simulation to steady-state. Extract contours of shear rate, substrate concentration, and local reaction rate. Calculate overall conversion.

Table 2: Example Results from Mesh Independence Study (Hypothetical Data)

| Mesh Size (elements) | Max Wall Shear Stress (Pa) | Predicted Outlet Conversion (%) | Computation Time (hr) |

|---|---|---|---|

| 50,000 | 0.85 | 76.2 | 0.5 |

| 200,000 | 0.91 | 74.8 | 2.1 |

| 800,000 | 0.92 | 74.5 | 8.5 |

| 2,000,000 | 0.92 | 74.5 | 22.0 |

Conclusion: Mesh with 800,000 elements provides a good compromise between accuracy and computational cost.

Protocol 3.2: Experimental Validation of Residence Time Distribution (RTD)

Objective: To experimentally determine the RTD of a fabricated 3D-printed reactor and validate the CFD-predicted flow behavior.

Materials:

- 3D-printed reactor (e.g., resin or metal).

- Peristaltic or syringe pump.

- Tracer solution (e.g., 1 M NaCl solution).

- Conductivity meter and data logger.

- Main fluid (deionized water).

Procedure:

- Setup: Connect the pump to the reactor inlet. Place the conductivity probe at the reactor outlet, connected to the data logger.

- Baseline: Pump DI water at the desired operational flow rate (Q) until a stable baseline conductivity (C_∞) is reached.

- Tracer Pulse Injection: Swiftly inject a small, sharp pulse of NaCl tracer (δt < 2% of mean residence time) into the inlet stream without interrupting flow.

- Data Collection: Record outlet conductivity (C(t)) at high frequency (e.g., 10 Hz) until it returns to baseline.

- Data Analysis: Calculate normalized concentration: E(t) = (C(t) - C_∞) / (∫_0^∞ (C(t) - C_∞) dt). Calculate mean residence time: τ_mean = ∫_0^∞ t·E(t) dt. Compare τ_mean to theoretical (V/Q).

Research Reagent & Material Solutions Toolkit

Table 3: Key Research Reagents and Materials for Biocatalytic Reactor Characterization

| Item | Function/Application | Example/Notes |

|---|---|---|

| Stereolithography (SLA) Resin (Biocompatible) | Fabrication of transparent reactors for flow visualization. | Formlabs Biocompatible Resin; allows rapid prototyping of complex geometries. |

| 316L Stainless Steel Powder | Metal 3D printing (SLM) for high-pressure/temperature biocatalytic reactions. | Provides chemical resistance and mechanical strength for industrial conditions. |

| Enzyme Immobilization Beads | Packing material for fixed-bed reactor designs. | Eupergit C, chitosan beads, or 3D-printed porous scaffolds functionalized with linkers (e.g., glutaraldehyde). |

| Fluorescent Tracer (e.g., Fluorescein) | Visualization of mixing and flow patterns in transparent reactors. | Used in Particle Image Velocimetry (PIV) or simple UV-light imaging studies. |

| Shear-Sensitive Enzyme Probe | Quantifying functional shear stress in validation experiments. | Catalase or other known shear-labile enzymes; loss of activity correlates with shear exposure. |

Visualization of Integrated Design Workflow

Diagram Title: Integrated Digital Design Workflow for 3D-Printed Biocatalytic Reactors

Diagram Title: Interplay of Key Parameters in Biocatalytic Reactor Performance

Within the thesis framework of designing advanced 3D-printed reactors for biocatalytic applications—such as enzyme immobilization and continuous-flow biotransformations—post-processing is a critical determinant of reactor performance. This document provides detailed application notes and standardized protocols for the curing, washing, and surface functionalization of 3D-printed parts, specifically for materials used in bioreactor fabrication (e.g., resins, polymers). Proper execution ensures structural integrity, biocompatibility, and provides chemically functional surfaces for subsequent biocatalyst attachment.

Post-Print Curing Protocols

Curing ensures complete photopolymerization of resin-based prints, maximizing mechanical strength and reducing leaching of uncured monomers—a crucial factor for reactor biocompatibility.

Protocol 1.1: Standard UV Post-Curing

Objective: To achieve final material properties and reduce cytotoxicity. Materials:

- UV curing chamber (wavelength 365-405 nm).

- Isopropyl Alcohol (IPA) for pre-wash.

- Nitrile gloves.

- Curing turntable (optional, for uniform exposure). Method:

- After printing, gently remove the part from the build platform.

- Submerge the part in a bath of fresh IPA for 2 minutes with gentle agitation to remove surface resin.

- Transfer the part to a second clean IPA bath for an additional 2 minutes.

- Allow the part to air-dry in a dark place for 15 minutes.

- Place the part in the UV curing chamber. For clear/translucent biocompatible resins, cure for 15-20 minutes per side at 25°C. For darker pigmented resins, increase time to 25-30 minutes per side.

- After curing, store the part in a clean, dark environment until ready for functionalization.

Table 1: Curing Parameters for Common Bioreactor Materials

| Material Type | Recommended Wavelength | Cure Time per Side | Post-Cure Temp | Key Property Achieved |

|---|---|---|---|---|

| Standard Clear Resin | 405 nm | 15 min | 25°C | Full Polymerization |

| Biocompatible Resin (Class I) | 365 nm | 20 min | 25°C | Cytotoxicity Reduction |

| High-Temp Resin | 405 nm | 25 min | 60°C | Thermal Stability |

| Flexible Resin | 385 nm | 20 min | 25°C | Elastic Modulus |

Washing and Cleaning Protocols

Effective washing removes support material, uncured oligomers, and processing aids that can foul catalysts or inhibit enzymes.

Protocol 2.1: Solvent-Based Washing for Resin Parts

Objective: To remove all uncured resin residue without degrading the part. Materials:

- Two ultrasonic baths.

- Fresh Isopropyl Alcohol (IPA, ≥99%).

- Deionized water.

- Dedicated waste containers. Method:

- Place the part with supports in the first ultrasonic bath containing IPA. Sonicate for 3 minutes at 40 kHz.

- Transfer the part to the second ultrasonic bath with clean IPA. Sonicate for an additional 3 minutes.

- Remove supports manually.

- Rinse the part thoroughly under a gentle stream of deionized water for 1 minute.

- Dry using filtered, oil-free compressed air or a nitrogen gun.

Surface Functionalization for Biocatalyst Immobilization

Surface modification creates reactive anchor points (e.g., amines, carboxyls) for covalent immobilization of enzymes or biofilms.

Protocol 3.1: Alkaline Hydrolysis for Generating Surface Carboxyl Groups

Objective: To hydrolyze ester groups in acrylate-based resins to generate hydrophilic, carboxyl-rich surfaces. Materials:

- 1.0 M Sodium Hydroxide (NaOH) solution.

- 0.1 M Hydrochloric Acid (HCl) solution.

- Phosphate Buffered Saline (PBS, pH 7.4).

- Orbital shaker or incubator. Method:

- Immerse the cured and washed part in 1.0 M NaOH solution. Agitate gently on an orbital shaker (50 rpm) for 4 hours at 40°C.

- Carefully remove the part and rinse with copious amounts of deionized water.

- Neutralize by immersing in 0.1 M HCl for 10 minutes.

- Rinse thoroughly with PBS (pH 7.4) to prepare for immobilization chemistry. Surface carboxyl density can be quantified via toluidine blue O assay.

Protocol 3.2: Silanization with (3-Aminopropyl)triethoxysilane (APTES) for Amine Groups

Objective: To introduce primary amine groups onto glass-filled or silica-containing printed/composite surfaces for enzyme coupling. Materials:

- (3-Aminopropyl)triethoxysilane (APTES), 2% (v/v) in anhydrous toluene.

- Anhydrous toluene.

- Oven set to 110°C.

- Desiccator. Method:

- Dehydrate the printed part in an oven at 110°C for 1 hour. Cool in a desiccator.

- Submerge the part in the 2% APTES/toluene solution for 2 hours at room temperature under an inert atmosphere (e.g., in a sealed vessel with argon).

- Rinse sequentially with fresh toluene, acetone, and ethanol to remove physisorbed silane.

- Cure the silane layer by heating at 110°C for 30 minutes. Store under dry conditions.

Table 2: Surface Functionalization Methods & Outcomes

| Method | Target Surface Group | Reaction Conditions | Immobilization Chemistry Enabled | Typical Binding Density |

|---|---|---|---|---|

| Alkaline Hydrolysis | Carboxyl (-COOH) | 1M NaOH, 40°C, 4h | EDC/NHS coupling to enzyme amines | 0.8-1.2 nmol/cm² |

| APTES Silanization | Amine (-NH₂) | 2% APTES, RT, 2h | Glutaraldehyde cross-linking | 3-5 nmol/cm² |

| Plasma Treatment | Hydroxyl (-OH) / Peroxy | O₂ Plasma, 100W, 1min | Direct adsorption or silanization precursor | Variable |

| UV-Induced Grafting | Variable (e.g., Acrylic Acid) | UV, Benzophenone, 30min | Direct copolymerization | 5-15 nmol/cm² |

The Scientist's Toolkit: Key Research Reagent Solutions

| Item | Function in Post-Processing & Functionalization |

|---|---|

| Isopropyl Alcohol (IPA), ≥99% | Primary solvent for washing uncured resin from vat polymerization prints. |

| (3-Aminopropyl)triethoxysilane (APTES) | Coupling agent for introducing primary amine groups onto hydroxylated surfaces. |

| 1-Ethyl-3-(3-dimethylaminopropyl)carbodiimide (EDC) | Zero-length crosslinker for activating carboxyl groups to couple with amines. |

| N-Hydroxysuccinimide (NHS) | Used with EDC to form stable amine-reactive NHS esters. |

| Glutaraldehyde (25% solution) | Homobifunctional crosslinker for coupling amine-modified surfaces to amine-bearing enzymes. |

| Toluidine Blue O dye | Used in colorimetric assay for quantifying surface carboxyl group density. |

| Anhydrous Toluene | Solvent for silanization reactions to prevent APTES hydrolysis prior to surface reaction. |

| Phosphate Buffered Saline (PBS), pH 7.4 | Standard buffer for rinsing and storing functionalized parts prior to biocatalyst immobilization. |

Experimental Workflow and Pathway Visualizations

Diagram Title: Workflow for 3D-Printed Bioreactor Post-Processing

Diagram Title: Surface Chemistries for Enzyme Immobilization

Enzyme Immobilization Techniques Directly onto 3D-Printed Surfaces.

1. Introduction and Context Within the broader thesis on 3D-printed reactor design for biocatalytic applications, the direct immobilization of enzymes onto the reactor's structural surface is a critical enabling technology. This approach eliminates the need for separate packing materials, enhances mass transfer by reducing diffusion paths, and enables the creation of complex, tailored flow geometries. Direct immobilization leverages the 3D printing process to create surfaces with inherent chemical functionality or post-printing modifications for enzyme coupling. These Application Notes provide a comparative overview of established techniques and detailed protocols for implementing them on 3D-printed substrates.

2. Comparison of Immobilization Techniques The choice of technique depends on the enzyme, 3D-printed polymer, and intended application. Key performance metrics are compared below.

Table 1: Comparison of Direct Enzyme Immobilization Techniques for 3D-Printed Surfaces

| Technique | Mechanism | Typical 3D Printing Materials | Advantages | Limitations | Immobilization Yield (Typical Range)* | Activity Retention* |

|---|---|---|---|---|---|---|

| Physical Adsorption | Hydrophobic/Ionic interactions | PLA, ABS, Nylon, Resins | Simple, no modification required, inexpensive | Leakage under operational conditions, non-specific | 10-50 µg/cm² | 20-70% |

| Covalent Binding | Formation of stable covalent bonds | Functionalized resins, surface-activated PLA, PEG-DA | High stability, no leakage, durable | Can cause enzyme denaturation, requires surface activation | 20-200 µg/cm² | 30-90% |

| Covalent via Spacers | Covalent binding with a molecular spacer (e.g., PEG) | Surface-activated materials (acrylates, amines) | Reduces steric hindrance, improves enzyme flexibility | Multi-step protocol, more complex chemistry | 15-100 µg/cm² | 50-95% |

| Bioaffinity | Specific non-covalent binding (e.g., His-Tag / Ni-NTA) | Metal-infused/composite polymers (e.g., with Cu, Ni) | Oriented immobilization, gentle, reversible | Requires genetic modification of enzyme, cost of functional resins | 5-40 µg/cm² | 60-100% |

| Entrapment/Encapsulation | Enzyme trapped within a polymer layer/matrix | Hydrogel resins (GelMA, PEG-DA), during printing | Protects enzyme from shear & denaturation | High diffusion barriers, potential enzyme leakage | N/A (bulk load) | 40-80% |

*Values are highly dependent on specific enzyme, surface chemistry, and immobilization conditions.

3. Detailed Experimental Protocols

Protocol 3.1: Covalent Immobilization via EDC/NHS Chemistry on Amine-Functionalized 3D-Printed Surfaces. Objective: To covalently immobilize carboxyl-containing enzymes onto a 3D-printed part with surface amine groups. Materials: 3D-printed part (e.g., from amine-containing resin or aminated post-processed PLA), enzyme solution (in low-ionic strength buffer, pH ~6-7), 2-(N-morpholino)ethanesulfonic acid (MES) buffer (0.1 M, pH 5.5), 1-ethyl-3-(3-dimethylaminopropyl)carbodiimide (EDC), N-hydroxysuccinimide (NHS), quenching buffer (e.g., 1 M Tris-HCl, pH 7.4), washing buffer (e.g., PBS with 0.05% Tween 20).

Procedure:

- Surface Activation: Prepare a fresh solution of EDC (40 mM) and NHS (10 mM) in cold MES buffer. Submerge the 3D-printed part in the activation solution. React for 15-30 minutes at room temperature with gentle agitation.

- Rinse: Quickly rinse the part three times with cold MES buffer to remove excess EDC/NHS.

- Enzyme Coupling: Immediately transfer the part to the enzyme solution (0.1-1.0 mg/mL in a suitable buffer, pH 7-8). Incubate for 2-4 hours at 4°C with gentle agitation.

- Quenching: Remove the part and submerge it in quenching buffer for 1 hour to block any remaining active esters.

- Washing: Wash the part thoroughly with washing buffer (3 x 10 min) and finally with storage buffer to remove any physisorbed enzyme.

- Characterization: Determine immobilization yield via Bradford assay of solution before/after coupling. Measure activity via a suitable enzymatic assay.

Protocol 3.2: Bioaffinity Immobilization of His-Tagged Enzymes on 3D-Printed Cu/PLA Composite. Objective: To exploit metal-affinity interactions for oriented immobilization of His-tagged enzymes. Materials: 3D-printed part from Cu-PLA composite filament, His-tagged enzyme, phosphate buffer (PBS, 20 mM, pH 7.4 with 300 mM NaCl), imidazole elution buffer (PBS with 300 mM imidazole, pH 7.4), blocking buffer (PBS with 1% BSA).

Procedure:

- Surface Conditioning: Wash the printed part with PBS buffer for 15 minutes.

- Blocking: Incubate the part in blocking buffer for 1 hour at 4°C to minimize non-specific binding.

- Enzyme Binding: Incubate the part with the His-tagged enzyme solution (in PBS, concentration optimized) for 2 hours at 4°C with gentle agitation.

- Washing: Wash with PBS buffer (5 x 5 min) to remove unbound enzyme.

- Elution (Optional, for characterization): To quantify bound enzyme, incubate the part in imidazole elution buffer for 15 min. Measure enzyme concentration in the eluate.

- Use: The immobilized enzyme reactor is ready for biocatalytic testing. For continuous flow, equilibrate with appropriate reaction buffer.

4. Visual Workflows

Title: Covalent Immobilization Workflow

Title: Immobilization Technique Decision Tree

5. The Scientist's Toolkit: Essential Reagents and Materials Table 2: Key Research Reagent Solutions for Direct Immobilization

| Item | Function/Benefit | Example/Note |

|---|---|---|

| Functionalized Resins | Provide inherent chemical handles (amines, acrylates) for direct coupling. | Methacrylate resins with pendant amines (e.g., PR48), PEG-DA resins. |

| Surface Activation Kits | Modify inert polymers (PLA, ABS) to introduce reactive groups (-OH, -NH₂, -COOH). | Plasma cleaner with reactive gases (O₂, NH₃), chemical amination kits. |

| Crosslinking Reagents | Facilitate covalent bond formation between enzyme and surface. | EDC, NHS, glutaraldehyde, genipin. |

| Spacer Arms | Reduce steric hindrance, improve enzyme activity retention. | Polyethylene glycol (PEG) diamine, succinimidyl esters with PEG spacers. |

| Metal-Composite Filaments | Enable bioaffinity immobilization without further modification. | Cu-PLA, Fe-PLA for His-tag and surface coordination chemistry. |

| Hydrogel Precursors | For entrapment methods, printed as encapsulating matrix. | Gelatin methacryloyl (GelMA), polyethylene glycol diacrylate (PEG-DA). |

| Blocking Agents | Reduce non-specific protein adsorption after immobilization. | Bovine Serum Albumin (BSA), casein, ethanolamine. |

| Activity Assay Kits | Quantify functional performance of the immobilized enzyme reactor. | Fluorogenic/colorimetric substrate kits specific to the enzyme (e.g., pNPP for phosphatases). |

This application note provides protocols for establishing continuous-flow biocatalytic systems, framed within a broader thesis on 3D-printed reactor design. The transition from batch to continuous biocatalysis offers significant advantages in productivity, reproducibility, and integration with downstream processing, particularly for pharmaceutical intermediate synthesis. This document details the core components—pumping systems, real-time monitoring, and process integration—required for robust operation.

Core System Components & Quantitative Comparison

Pump Selection for Biocatalytic Flow Systems

The choice of pump is critical for maintaining enzyme stability and consistent residence time. Key parameters are summarized below.

Table 1: Quantitative Comparison of Pump Technologies for Biocatalytic Flow

| Pump Type | Flow Rate Range (µL/min to mL/min) | Pulse Frequency (Hz) | Recommended Max Pressure (bar) | Biocompatibility / Shear Stress Concern | Typical Use Case in Biocatalysis |

|---|---|---|---|---|---|

| Syringe Pump | 0.01 - 500 mL/min | <0.01 (High pulsation at low flow) | 10-20 | High (Low shear) | Lab-scale screening, precise substrate feed. |

| Peristaltic Pump | 0.05 - 4000 mL/min | 1-100 | 2-6 | Medium (Moderate shear) | Pilot-scale production, recycling of immobilized enzymes. |

| HPLC Pump | 0.001 - 100 mL/min | >100 (Damped pulsation) | 400 | High (Low shear) | High-pressure applications, packed-bed reactors. |

| Diaphragm Pump | 10 - 5000 mL/min | 50-200 | 8-16 | Low (High shear) | Buffer or solvent delivery where enzyme contact is indirect. |

| Gear Pump | 1 - 5000 mL/min | Continuous | 15 | Low (High shear) | Viscous process streams, post-reaction quenching. |

In-line Monitoring Techniques

Real-time analytics are essential for closed-loop control. The following table compares common methods.

Table 2: Key Parameters for In-line Monitoring Techniques

| Technique | Measured Parameter | Response Time (s) | Limit of Detection (Typical) | Compatibility with Aqueous / Organic Flow | Suitability for Enzyme Stability Monitoring |

|---|---|---|---|---|---|

| In-line FTIR / ATR | Functional group conversion | 5-30 | ~0.1% (concentration dependent) | High (Requires IR-transparent window) | Medium (Can probe cofactor states). |

| In-line UV/Vis | Concentration, enzyme cofactors | 1-5 | µM range | High (Requires flow cell) | High (Direct NAD(P)H monitoring). |

| In-line pH / Conductivity | Proton release/uptake, ionic strength | <1 | 0.01 pH units | High | High (For reactions producing/consuming acids). |

| In-line HPLC/UHPLC | Multi-analyte separation | 60-300 | nM-µM range | High | Low (Sampling interface complexity). |

| In-line Mass Spectrometry | Molecular weight, conversion | 1-10 | nM range | Medium (Interface challenges) | Low. |

Experimental Protocols

Protocol 3.1: Assembly and Priming of a Low-Shear Continuous-Flow System for Immobilized Enzyme Cartridges

Objective: To establish a pulsation-damped, low-shear flow system for a packed-bed reactor containing immobilized transaminase.

Materials:

- 3D-printed reactor housing (e.g., PEEK or coated resin) with cartridge interface.

- 2x Syringe pumps (Pump A: substrate; Pump B: cofactor recycle stream).

- Damping unit (e.g., 5 m x 0.5 mm ID PFA tubing coil or commercial pulse damper).

- In-line pressure sensor (0-10 bar range).

- Immobilized enzyme cartridge (e.g., transaminase on controlled-pore glass).

- Back-pressure regulator (set to 2 bar).

- In-line UV flow cell (path length: 2 mm) and detector.

- Data acquisition/control software (e.g., LabVIEW, Python with NI-DAQ).

Method:

- System Assembly: Connect Pump A outlet to the damping unit inlet using 1/16" OD tubing and fingertight fittings. Connect the damping unit outlet to a mixing tee.

- Connect Pump B outlet to the second port of the mixing tee.

- Connect the mixing tee outlet to the inlet of the immobilized enzyme cartridge housed in the 3D-printed reactor block.

- Connect the cartridge outlet sequentially to: a) the in-line pressure sensor, b) the in-line UV flow cell, and c) the back-pressure regulator.

- Priming and Leak Check: Fill all pump lines and the damping unit with reaction buffer (e.g., 50 mM potassium phosphate, pH 7.5). Set both pumps to a high flow rate (e.g., 1 mL/min) and run until all air bubbles are purged from the tubing, fittings, and the UV cell. Visually inspect all connections for leaks.

- Flow Rate Calibration: Prime the system with buffer. Collect effluent from the back-pressure regulator outlet in a pre-weighed vial for a precisely timed interval (e.g., 300 s). Calculate the actual flow rate (mass collected / (time * density)). Adjust the pump calibration factor until the set point matches the actual flow rate within ±2%.

- System Operation: Load substrate and cofactor solutions into Pump A and B syringes, respectively. Set to desired flow rates to achieve target residence time (τ = reactor volume / total flow rate). Initiate flow and monitor pressure and UV absorbance (e.g., 340 nm for NADH) until stable baselines are achieved before collecting product fractions.

Protocol 3.2: Integration of In-line ATR-FTIR for Reaction Progress Monitoring

Objective: To implement real-time conversion analysis for a continuous-flow ketoreductase-catalyzed reaction.

Materials:

- Continuous-flow microreactor (3D-printed, with integrated or externally coupled ATR crystal).

- FTIR spectrometer with flow-through ATR accessory (e.g., diamond crystal).

- Peristaltic pump with fluoropolymer tubing.

- Standard solutions of substrate (ketone) and product (alcohol) for calibration.

Method:

- Calibration Model Development: Prepare a series of standard mixtures of ketone and alcohol in reaction solvent spanning 0-100% conversion. Pump each standard through the ATR cell at a constant flow rate (e.g., 0.5 mL/min).

- Acquire IR spectra (e.g., 16 scans at 4 cm⁻¹ resolution) for each standard. Identify a characteristic peak for the ketone C=O stretch (e.g., ~1715 cm⁻¹) and the alcohol O-H stretch (e.g., broad peak ~3300 cm⁻¹).

- Using spectroscopic software, create a univariate calibration model (peak height or area vs. concentration) or a partial least squares (PLS) multivariate model using the relevant spectral region.

- In-line Monitoring: Connect the effluent stream from the biocatalytic reactor directly to the ATR flow cell. Pump at a constant rate exceeding the spectrometer measurement frequency to ensure a fresh sample for each scan.

- Acquire spectra continuously (e.g., every 30 seconds). Apply the calibration model in real-time to convert spectral data into concentration or conversion percentage. Output the conversion vs. time data to a process control dashboard.

System Integration Diagrams

Title: Integrated Flow Biocatalysis System with PAT Control

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Continuous-Flow Biocatalysis Research

| Item / Reagent Solution | Function in Continuous-Flow Biocatalysis | Key Consideration for 3D-Printed Reactors |

|---|---|---|

| Immobilized Enzyme Kits (e.g., EziG carriers, immobilized CALB on acrylic resin) | Provides robust, reusable biocatalysts for packed-bed or segmented flow reactors. Enables high catalyst loading and prevents protein fouling of reactor channels. | Compatibility of carrier size (e.g., 100-300 µm) with 3D-printed frits or mesh features to retain catalyst. |

| Cofactor Recycling Systems (e.g., NADH/NADPH with glucose dehydrogenase (GDH); Formate with FDH) | Regenerates expensive cofactors in situ, making processes economically viable. Often requires a second enzyme. | May require separate immobilized enzyme beds or co-immobilization strategies within a single reactor cartridge. |

| Stabilizing Buffers & Additives (e.g., Trehalose, Polyethyleneimine (PEI), Glycerol) | Enhances enzyme longevity under continuous flow conditions by reducing shear-induced denaturation and interfacial inactivation. | Additives must not cause swelling or degradation of 3D-printed polymer resins (e.g., certain organic solvents). |

| Blocking & Passivation Solutions (e.g., 1% BSA, Silane-PEG solutions) | Reduces non-specific adsorption of enzymes or products onto reactor and tubing surfaces, crucial for accurate yield determination and maintaining flow. | Essential for 3D-printed resins which can have high surface roughness and residual leachables. |

| In-line Quenching Reagents (e.g., acidic or basic streams, enzyme inhibitors) | Rapidly stops the reaction post-reactor for accurate off-line analysis or before purification. | Requires a secondary, precisely controlled pump and a mixing zone (e.g., a 3D-printed static mixer) integrated post-PAT. |

| Calibration Standards for PAT (e.g., Certified pH buffers, analyte-specific UV/IR standards) | Enables quantitative calibration of in-line sensors (pH, UV, FTIR) for real-time conversion calculation. | Standards must be flowed through the exact same flow path as the reaction mixture to account for cell path length and window material. |

Within the broader thesis on 3D-printed reactor design for biocatalytic applications, this document explores case studies in the pharmaceutical synthesis of chiral intermediates and Active Pharmaceutical Ingredients (APIs). The convergence of enzyme engineering, flow chemistry, and advanced reactor fabrication is enabling more sustainable, efficient, and precise manufacturing routes for complex molecules. These application notes and protocols detail current methodologies, emphasizing processes amenable to implementation in novel 3D-printed bioreactor systems.

Application Notes

Note 1: Biocatalytic Synthesis of Sitagliptin Intermediate

Sitagliptin, a DPP-4 inhibitor for type 2 diabetes, requires a chiral amine intermediate. Traditional chemical synthesis used a metal-catalyzed asymmetric hydrogenation. A biocatalytic route was developed using an engineered transaminase.

Key Performance Data: Table 1: Comparison of Chemical vs. Biocatalytic Synthesis for Sitagliptin Intermediate

| Parameter | Chemical Route (Rh/Josiphos) | Biocatalytic Route (Engineered Transaminase) |

|---|---|---|

| Yield | 97% | 92% |

| Enantiomeric Excess (ee) | >99.5% | >99.95% |

| Productivity (g/L/day) | 160 | 200 |

| E Factor (kg waste/kg product) | ~58 | ~19 |

| Step Count | 4 steps (from prochiral ketone) | 1 step (single enzymatic transamination) |

Research Reagent Solutions Toolkit: Table 2: Essential Reagents for Transaminase-Catalyzed Synthesis

| Reagent/Material | Function in the Process |

|---|---|

| (R)-ω-Transaminase (Engineered) | Key biocatalyst; catalyzes the asymmetric amination of a pro-sitagliptin ketone to the chiral amine. |

| PLP (Pyridoxal-5'-phosphate) | Essential cofactor for transaminase activity. |

| Isopropylamine | Amine donor, driving the reaction equilibrium toward product formation. |

| Ketone Substrate (pro-sitagliptin) | The prochiral precursor molecule to be aminated. |

| Phosphate Buffer (pH 7.5) | Provides optimal pH environment for enzymatic activity. |

| 3D-Printed Flow Reactor (e.g., with immobilized enzyme) | Proposed reactor design for continuous processing, improving productivity and catalyst reuse. |

Note 2: Chemoenzymatic Synthesis of Islatravir Intermediate

Islatravir, an investigational nucleoside reverse transcriptase inhibitor, features a chiral cyclopentane core. A chemoenzymatic dynamic kinetic resolution (DKR) using a ketoreductase (KRED) and an iridium catalyst was developed.

Key Performance Data: Table 3: Performance Metrics for Islatravir Intermediate DKR Process

| Parameter | Value |

|---|---|

| Conversion | >99% |

| Diastereomeric Excess (de) | >99.9% |

| Yield (isolated) | 91% |

| Turnover Number (TON) - Enzyme | >5,000 |

| Turnover Number (TON) - Metal | >1,500 |

| Space-Time Yield (g/L/h) | 85 |

Research Reagent Solutions Toolkit: Table 4: Essential Reagents for DKR Synthesis

| Reagent/Material | Function in the Process |

|---|---|

| Ketoreductase (KRED, engineered) | Biocatalyst that selectively reduces one enantiomer from the racemizing mixture. |

| NADP+ (Nicotinamide adenine dinucleotide phosphate) | Oxidized cofactor; recycled in situ by the enzyme and sacrificial donor. |

| Iridium-based Racemization Catalyst | Catalyzes the in-situ racemization of the unfavored alcohol enantiomer back to ketone. |

| 2-Propanol | Solvent and sacrificial electron donor for cofactor recycling. |

| Racemic cis/trans Alcohol Substrate | Starting material for the dynamic kinetic resolution. |

| 3D-Printed Packed-Bed Reactor | Proposed design to compartmentalize or co-immobilize enzymatic and metal catalysts. |

Experimental Protocols

Protocol 1: Continuous Flow Transamination for Chiral Amine Synthesis

This protocol details the enzymatic synthesis of a chiral amine intermediate, optimized for a continuous flow system utilizing enzyme immobilization on a 3D-printed reactor scaffold.

Materials:

- Engineered (R)-ω-transaminase (lyophilized powder)

- Pyridoxal-5'-phosphate (PLP)

- Prochiral ketone substrate (e.g., 100 mM in DMSO)

- Isopropylamine hydrochloride (500 mM, pH adjusted to 7.5)

- Potassium phosphate buffer (1.0 M, pH 7.5)

- 3D-printed reactor with designed surface area/geometry for immobilization

- Immobilization resin (e.g., epoxy-activated methacrylate beads)

- Peristaltic or HPLC pumps

- In-line UV detector

Methodology:

- Enzyme Immobilization: Rehydrate transaminase (50 mg) in phosphate buffer (5 mL, 100 mM, pH 7.5) with PLP (0.1 mM). Mix with epoxy-activated resin (1 g) and incubate on a roller at 4°C for 16 hours. Wash thoroughly with buffer and pack into the 3D-printed reactor chamber.

- Reagent Preparation: Prepare Feed A: Ketone substrate (100 mM) and PLP (0.1 mM) in 100 mM phosphate buffer (pH 7.5) with 10% v/v DMSO. Prepare Feed B: Isopropylamine (1.0 M) in 100 mM phosphate buffer (pH 7.5).

- System Setup: Connect Feed A and B lines via a T-mixer prior to the reactor inlet. Connect the reactor outlet to an in-line UV detector (monitoring at 254 nm) and then to a fraction collector. Maintain system temperature at 30°C using a water jacket or incubator.

- Process Execution: Initiate flow at a combined flow rate of 0.2 mL/min (residence time ~30 min). Collect effluent and monitor conversion via in-line UV or periodic offline HPLC analysis.

- Work-up & Analysis: Acidify collected fractions to pH 2.0, extract with ethyl acetate to remove unreacted ketone, then basify to pH 12.0 and extract the chiral amine product into fresh ethyl acetate. Dry over anhydrous Na₂SO₄, concentrate, and determine yield, ee (by chiral HPLC), and conversion.

Protocol 2: Dynamic Kinetic Resolution in a Batch Bioreactor

This protocol describes the one-pot DKR process for the synthesis of a chiral alcohol, a precursor to Islatravir.

Materials:

- Ketoreductase (KRED) enzyme solution (20 mg/mL)

- NADP+ sodium salt (2 mM final concentration)

- Iridium racemization catalyst ([Cp*Ir(dmpy)Cl]Cl, 0.5 mol%)

- Racemic alcohol substrate (50 mM)

- 2-Propanol (5% v/v, as cosolvent and sacrificial donor)

- Potassium phosphate buffer (100 mM, pH 7.0)

- Orbital shaker incubator

Methodology:

- Reaction Setup: In a 50 mL conical flask, add magnetic stir bar, phosphate buffer (10 mL), racemic alcohol substrate (from a 500 mM stock in 2-propanol), NADP+ (from a 20 mM stock in buffer), and the iridium catalyst (from a 10 mM stock in DMSO).

- Initiation: Place the flask in an incubator set to 30°C and 250 rpm. Start the reaction by adding the KRED enzyme solution (1 mL, 20 mg/mL).

- Monitoring: Withdraw 100 µL aliquots periodically (e.g., 0, 1, 2, 4, 8, 24 h). Quench each aliquot with 900 µL of acetonitrile, vortex, centrifuge, and analyze the supernatant by chiral HPLC to determine conversion and diastereomeric excess.

- Termination & Extraction: After >99% conversion is confirmed (typically 24-48 h), quench the reaction by adding 10 mL of ethyl acetate. Separate the organic layer. Extract the aqueous layer twice more with ethyl acetate. Combine organic layers, dry over anhydrous Na₂SO₄, and concentrate under reduced pressure.

- Purification: Purify the crude product by flash chromatography to obtain the desired chiral alcohol. Calculate isolated yield and confirm de by chiral HPLC or NMR.

Visualizations

Title: Sitagliptin Intermediate Biocatalytic Synthesis Workflow

Title: Dynamic Kinetic Resolution Pathway for Islatravir

Title: Integrated Continuous Biocatalytic Reactor System

Overcoming Challenges: Practical Solutions for Optimizing 3D-Printed Biocatalytic Reactor Performance

Addressing Common Print Defects and Their Impact on Fluid Dynamics and Enzyme Loading

Within the thesis on "Advanced 3D-Printed Reactor Design for High-Efficiency Biocatalytic Processing," a critical challenge is the variability introduced by additive manufacturing. This document details the most prevalent 3D printing defects, their quantifiable impact on reactor performance metrics (fluid dynamics and enzyme immobilization loading/capacity), and provides validated protocols for their identification and mitigation.

Common Print Defects: Characterization and Impact

The following table summarizes key defects, their root causes, and primary impacts on reactor function.

Table 1: Common 3D Printing Defects and Their Functional Impacts