Sweetening the Mix

Enzymes Craft Valuable Lactose Molecules Where Water Can't

Article Navigation

Introduction

Imagine trying to mix oil and water. Now, imagine trying to perform delicate molecular surgery on an oily substance using water-based tools. That's essentially the challenge scientists face when trying to modify hydrophobic (water-fearing) alcohols with valuable sugars like lactose. But a groundbreaking approach, nonaqueous biocatalysis, is turning this challenge into an opportunity, enabling a powerful one-step lactosylation reaction.

The Challenge

Hydrophobic alcohols don't mix with water, making traditional enzymatic reactions difficult or impossible.

The Solution

Nonaqueous biocatalysis allows enzymes to work in organic solvents, enabling direct modification of hydrophobic molecules.

The Powerhouse Experiment: Lactose Meets Octanol in a Dry Dance

A pivotal 2024 study from the University of Milan vividly demonstrated the potential of this one-step nonaqueous lactosylation.

Experimental Method

- Setting the Stage: Prepared a reaction mixture entirely free of water.

- The Actors:

- 1-Octanol (10 mmol) - the hydrophobic alcohol

- Vinyl lactoside (12 mmol) - activated lactose donor

- Thermomyces lanuginosus Lipase (TLL) (50 mg) - the enzyme catalyst

- Anhydrous tert-Butanol (5 mL) - the dry organic solvent

- The Performance: Mixture sealed and gently shaken at 50°C for 24 hours.

- The Finale: Products analyzed using HPLC and Mass Spectrometry.

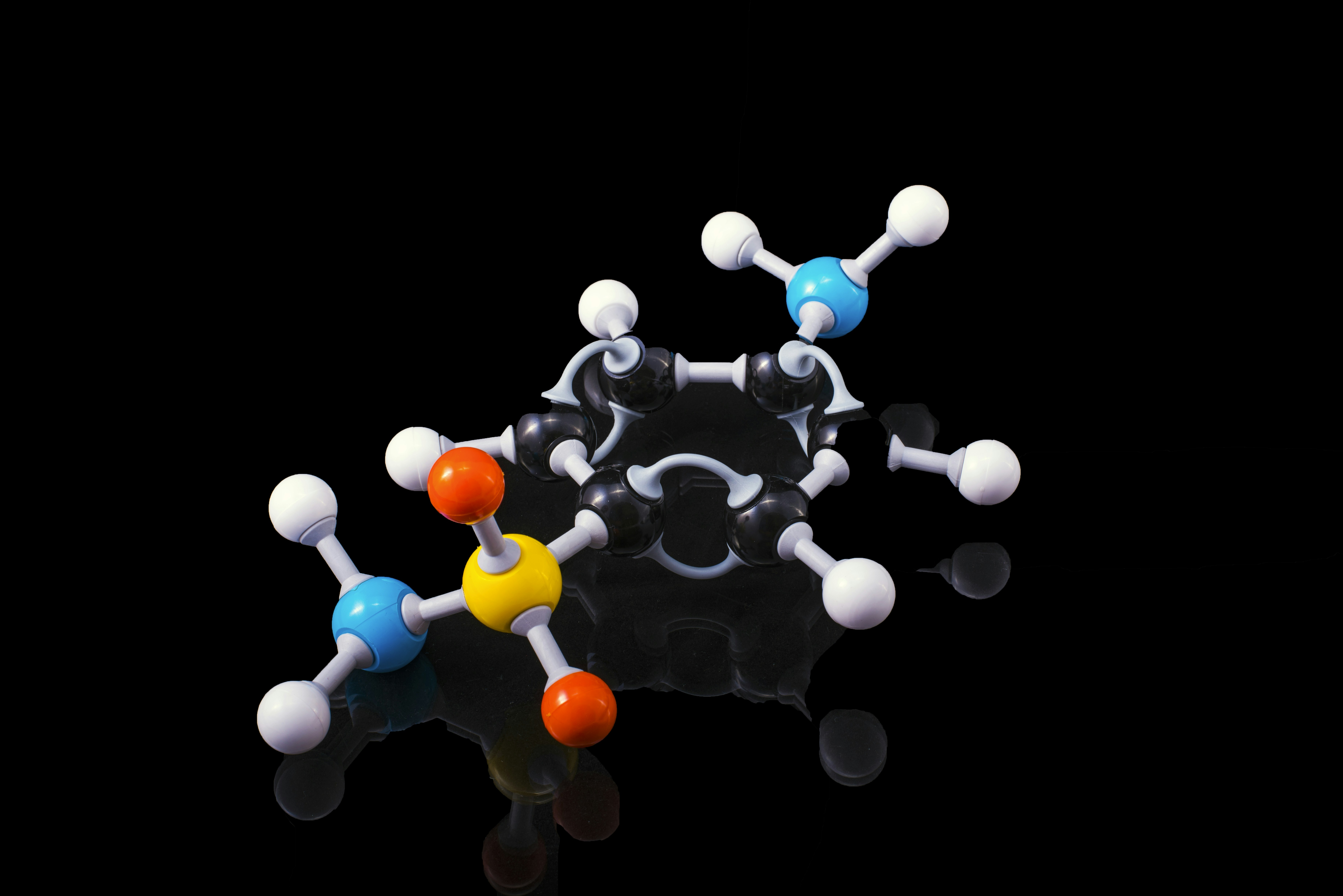

Experimental setup for nonaqueous biocatalysis (illustrative image)

The Encore: Results and Why They Rocked

85%

Yield of octyl lactoside

>99%

Regioselectivity

90%

Enzyme activity retained

Data Visualization

Detailed Data Tables

| Solvent | Log P* | Yield (%) | Regioselectivity (%) | Enzyme Activity Remaining (%) |

|---|---|---|---|---|

| tert-Butanol | 0.80 | 85 | >99 | 92 |

| Acetone | -0.24 | 15 | 95 | 75 |

| THF | 0.49 | 42 | 98 | 85 |

| Toluene | 2.50 | 68 | >99 | 78 |

| Solvent-Free | N/A | 72 | >99 | 88 |

Scientific Significance

This experiment wasn't just a success; it was a blueprint. It proved definitively that:

- Enzymes can perform complex sugar chemistry on hydrophobic molecules

- This can be achieved in a single step

- It works under mild, green conditions (moderate temperature, no toxic metals, minimal waste)

- It offers exceptional precision (high regioselectivity)

- The enzymes are tough enough for the job

Substrate Versatility

The method successfully lactosylated a range of structurally diverse hydrophobic alcohols:

The Scientist's Toolkit

Pulling off this molecular magic requires some key ingredients and tools:

Lipase Enzyme

The biological catalyst that performs the precise lactosylation in organic solvents.

Activated Lactose Donor

Provides the lactose molecule in a high-energy form the enzyme can readily transfer.

Anhydrous Solvent

Water-free reaction medium that dissolves hydrophobic substrates while keeping the enzyme active.

Molecular Sieves

Scavenges any trace water molecules, keeping the environment strictly nonaqueous.

Hydrophobic Alcohol

The target molecule to be modified (e.g., 1-Octanol, Benzyl Alcohol, Cholesterol).

Analytical Tools

HPLC and Mass Spectrometry to separate, identify, and quantify the reaction products.

A Sweeter Future, Built Greener

Potential Applications

Pharmaceuticals

Improved drug solubility and delivery systems

Cosmetics

Novel bioactive ingredients with better skin penetration

Food Additives

Functional ingredients with improved properties

Green Chemistry

Sustainable production methods with minimal waste

The Big Picture

The one-step lactosylation of hydrophobic alcohols using nonaqueous biocatalysis is more than a lab trick; it's a paradigm shift. By harnessing the precision of enzymes outside their natural aqueous habitat, chemists can now create valuable lactose-modified molecules with unprecedented efficiency, selectivity, and environmental friendliness.

The fusion of biology and solvent engineering is truly sweetening the pot for green chemistry and innovative product development.